Zip head moving device for zip assembly line

A mobile device and assembly line technology, applied in the direction of application, sliding fastener components, fasteners, etc., can solve problems such as increased cost, poor cutting, poor upper stop structure, etc., and achieve the effect of saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

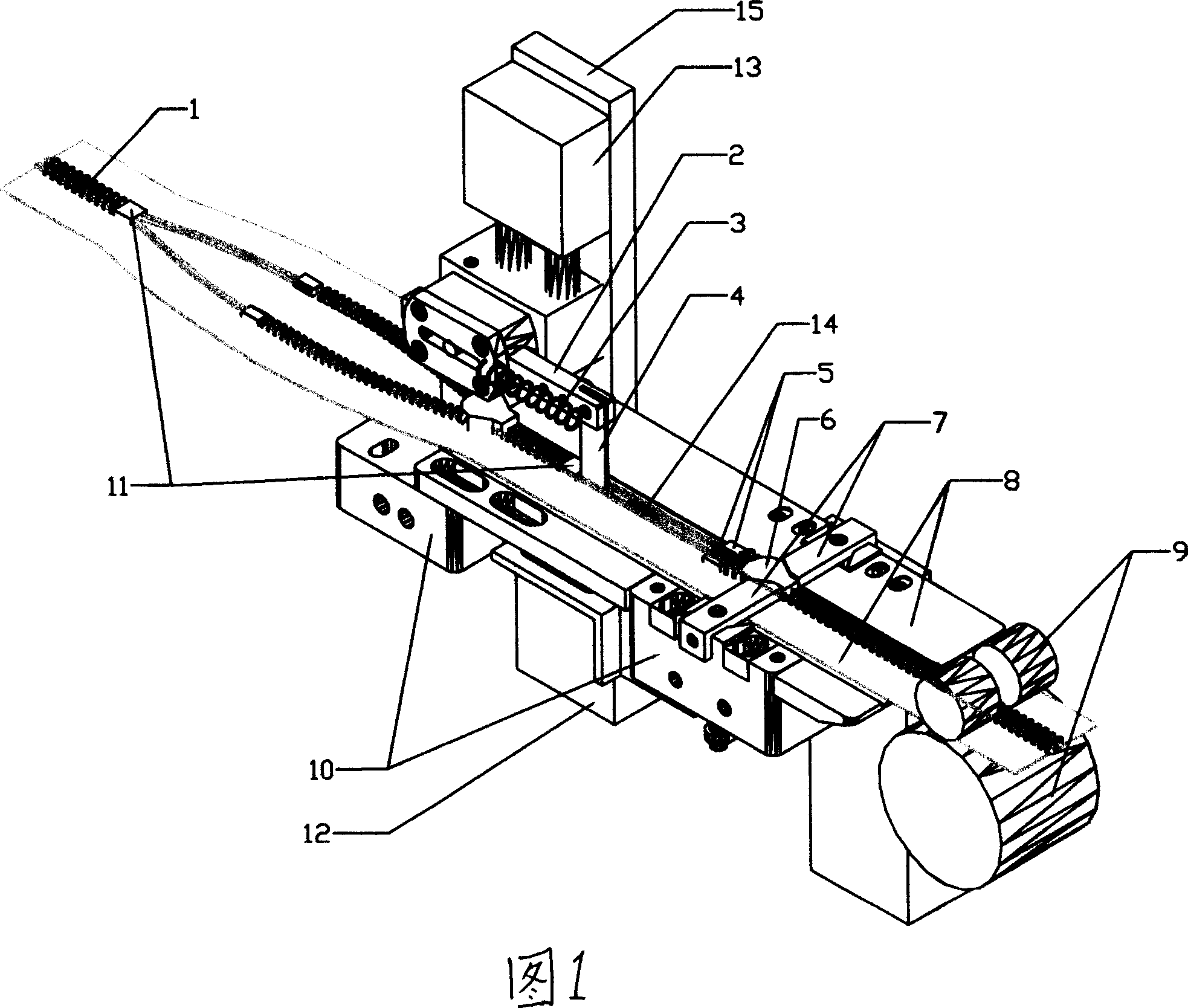

[0018] As shown in Figure 1, the base 10 is fixedly connected to the chain guide plate 8, the pulley 9 is connected to the rear end of the chain guide plate 8, and the left and right stoppers 7 of the slider that can rotate at a certain angle are set on the chain guide plate 8. The left and right setting directions of the left and right stoppers 7 are perpendicular to the chain guide plate 8, that is, perpendicular to the processing direction of the uncut zipper tape 1. The slider 6 can be caught and the zipper tape 1 can be passed through, and the slider 6 can be passed after turning. The rear end of the chain guide plate 8 is provided with a pulling pulley 9 for controlling the movement of the zipper belt 1 at a constant speed.

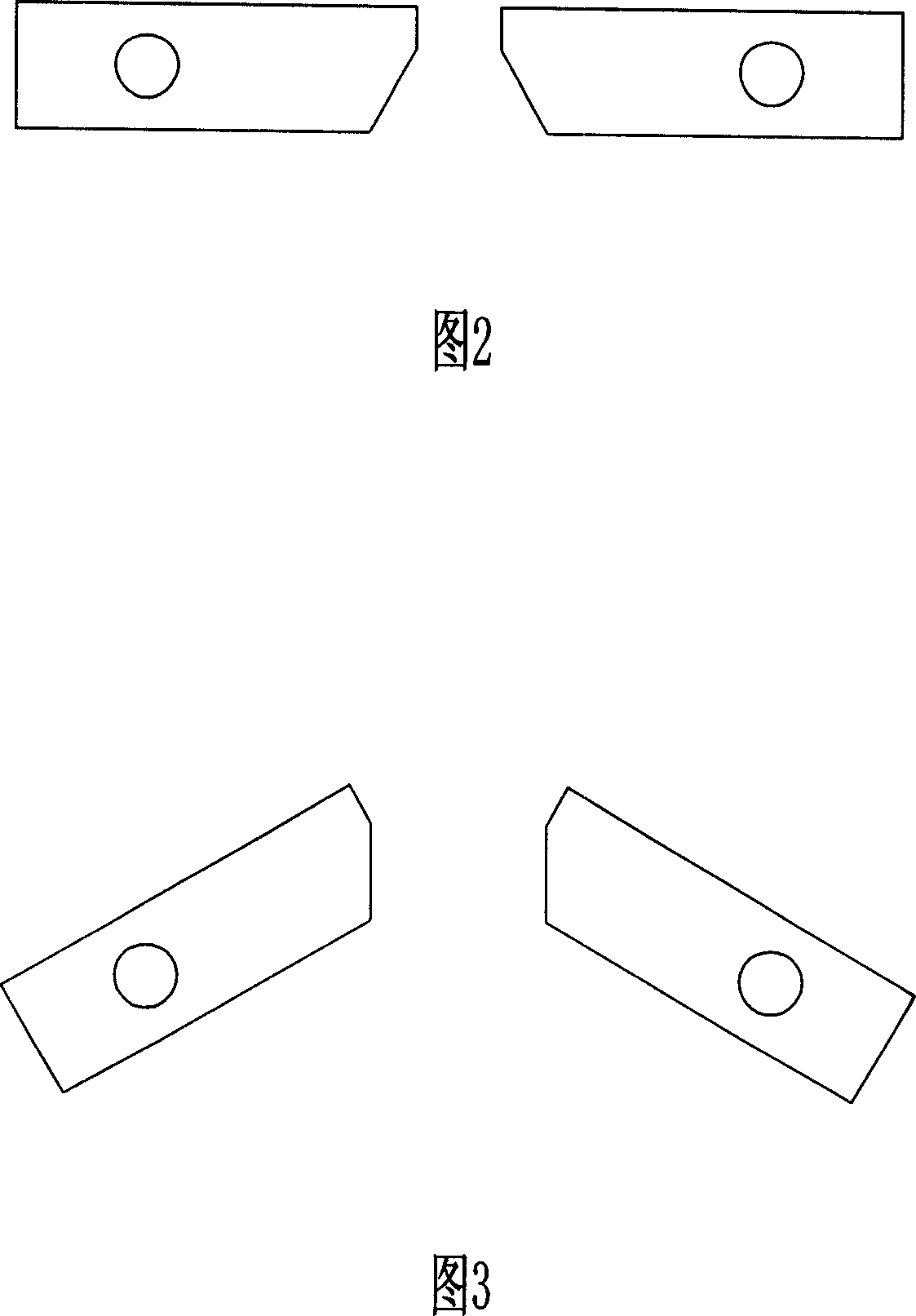

[0019] As shown in FIG. 2 , it is a schematic diagram when the left and right stoppers 7 of the slider ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com