Novel cutter-exchange mechanism for manipulator

A tool changing mechanism and manipulator technology, applied in metal processing mechanical parts, clamping, support and other directions, can solve the problems of unsatisfactory tool change reliability, large manipulator swing angle, low work efficiency, etc. The effect of fast knife speed and small swing angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

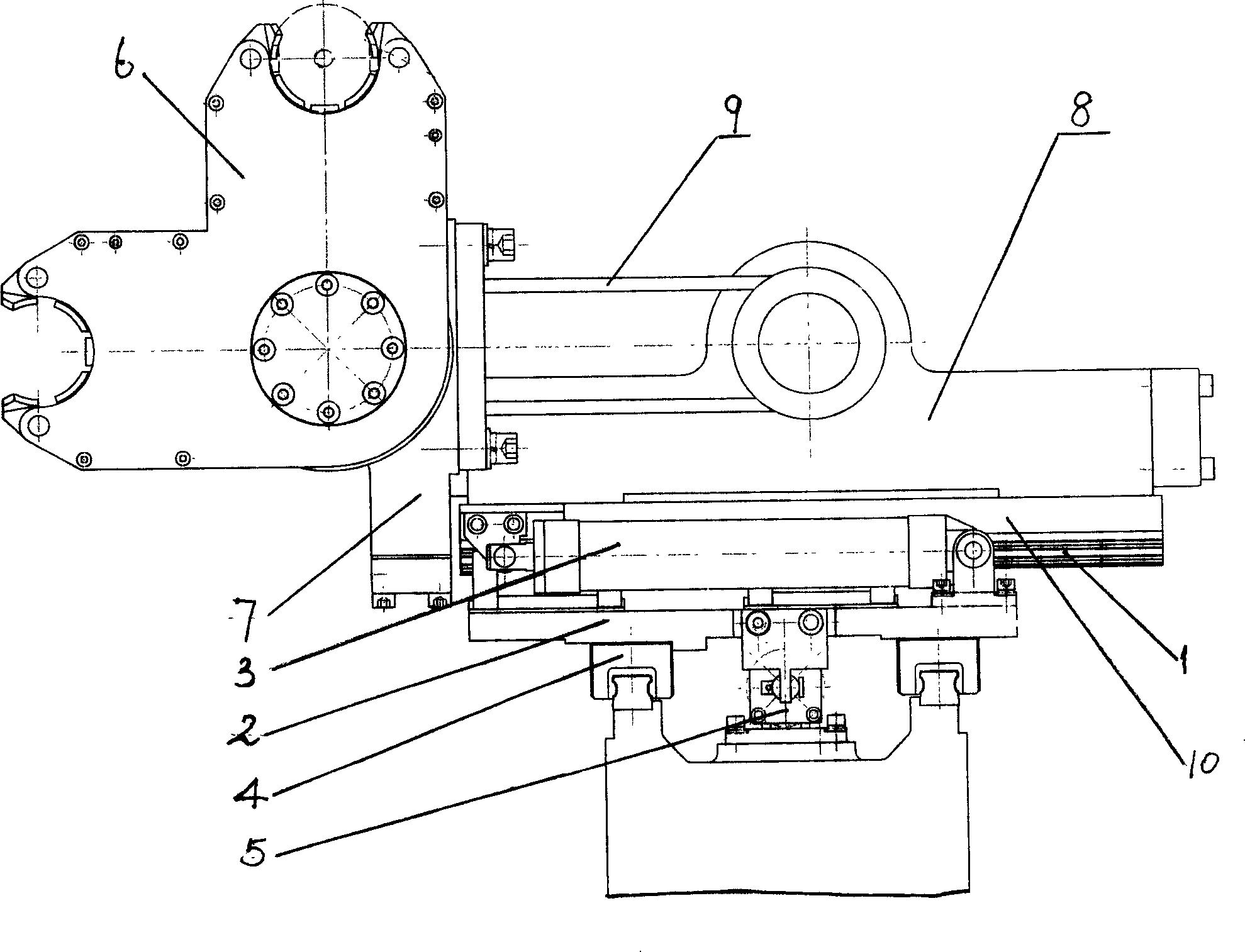

[0009] A new manipulator tool changing mechanism, including a manipulator swing device, the manipulator swing device is installed on the X-axis linear guide rail pair 1 through the second slide seat 10, and is connected with the second oil cylinder 3 installed on the first slide seat 2, the second A sliding seat 2 is installed on the Y-axis linear guide rail pair 4, and is connected with the first oil cylinder 5; the manipulator swing device includes a manipulator 6, and the manipulator 6 is connected with the first swing cylinder 7 that can swing at 90°. The second swing cylinder 8 of 180 ° swing is connected. The swing arm 9 of the second swing cylinder 8 is also shown in the figure.

[0010] In this tool change mechanism, the manipulator moves along the Y-axis coordinates along the linear guide rail pair 4 under the drive of the first oil cylinder 5, so as to realize the movement of the manipulator to draw and install the tool to the tool magazine or the main shaft; Under ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com