A control arm assembly

A technology for controlling arms and assemblies, which is applied to cantilevers mounted on pivots, elastic suspensions, suspensions, etc. The problem of increasing the force of the arm can reduce the difficulty of optimization, reduce the space, and improve the force condition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be further described in detail below through the accompanying drawings and embodiments.

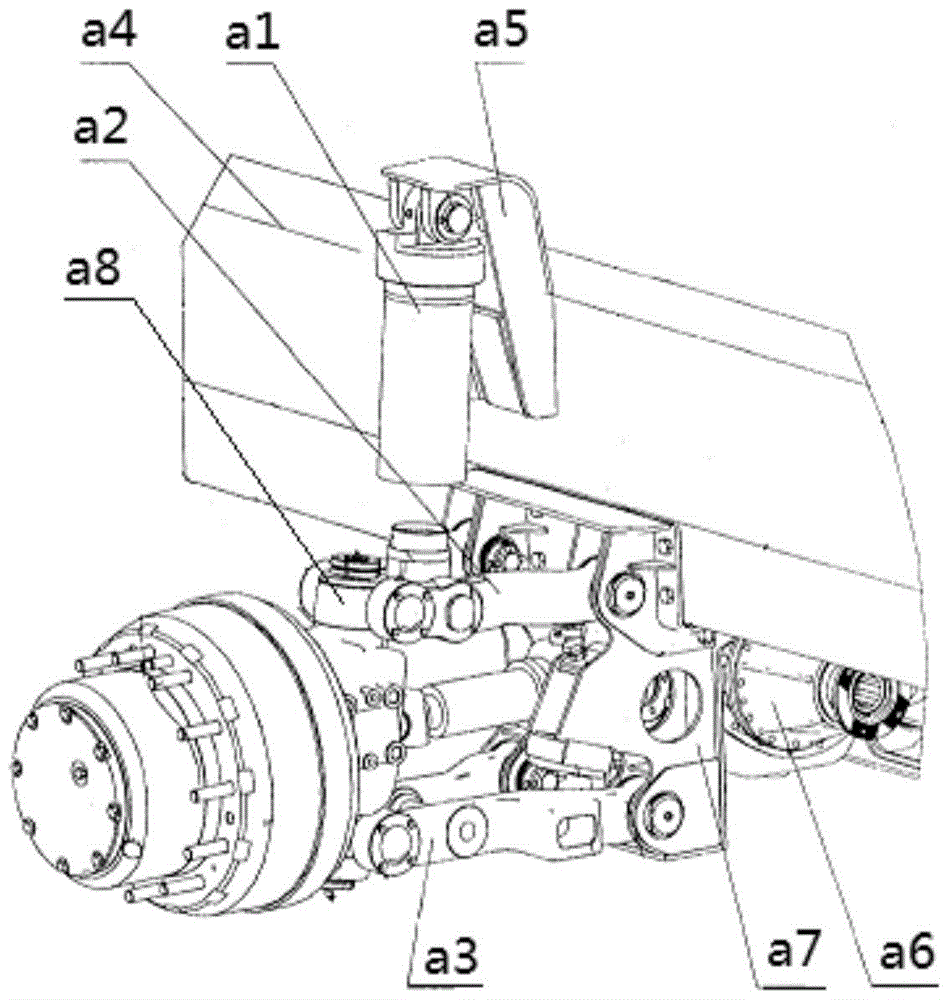

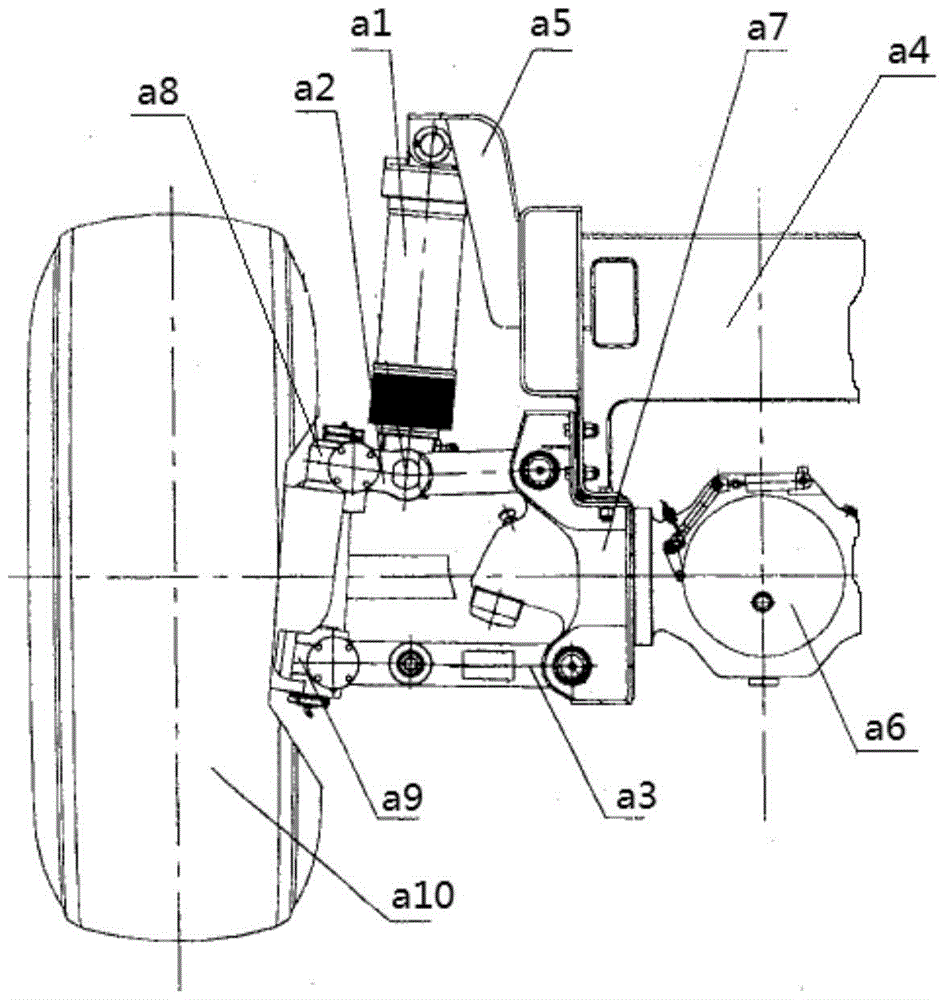

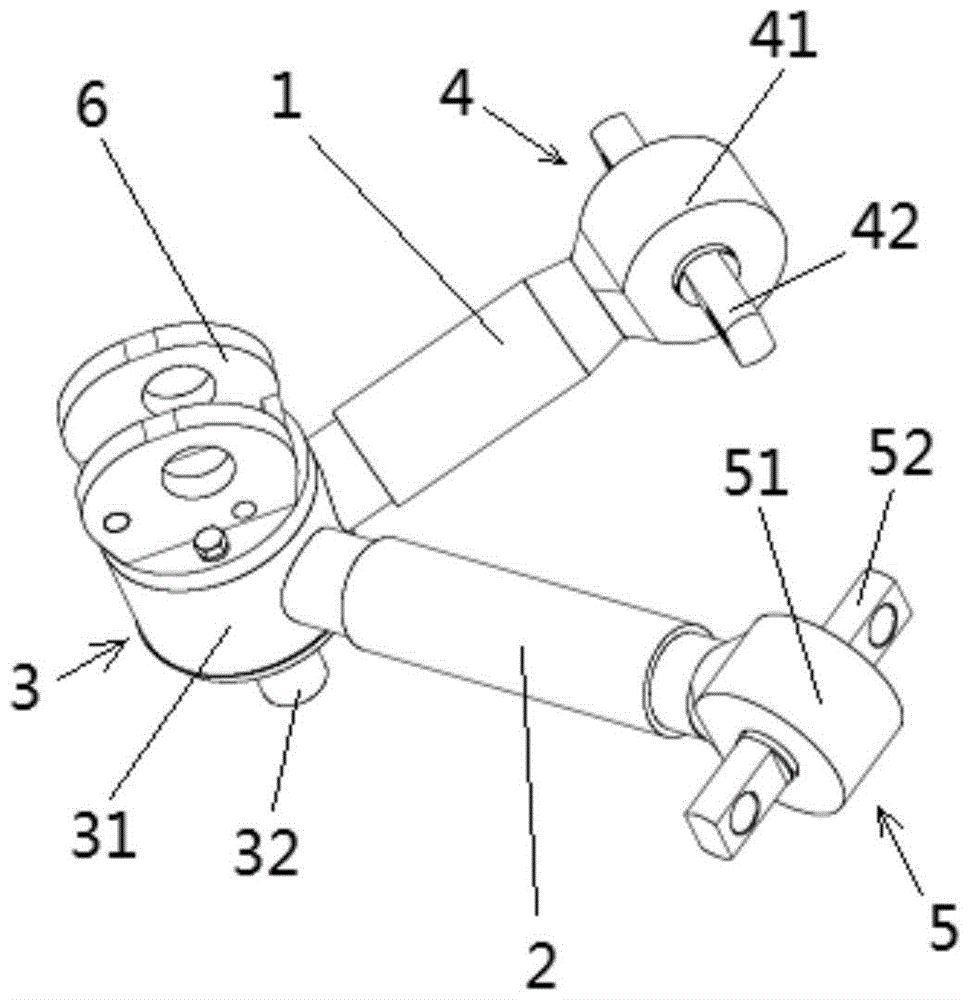

[0028] Such as image 3 Shown is a schematic structural diagram of an embodiment of the control arm assembly of the present invention. The control arm assembly in this embodiment can be applied to an independent suspension structure of a vehicle, for example, as an upper cross arm assembly or a lower cross arm assembly. Among them, the control arm assembly includes two V-shaped connecting arms 1, 2 and three spherical hinge structures 3, 4, 5 respectively arranged at the ends of the two connecting arms 1, 2. Two connecting arms 1 , 2 each have one end connected to the first spherical hinge structure 3, and the other ends of the two connecting arms 1, 2 are respectively connected to the second spherical hinge structure 4 and the third spherical hinge structure 5. Among the three ball hinge structures, the first ball hinge structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com