Hybrid-drive vehicle

A hybrid vehicle and hybrid operation technology, applied in the direction of hybrid vehicles, motor vehicles, power plants, etc., can solve problems such as weakened efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

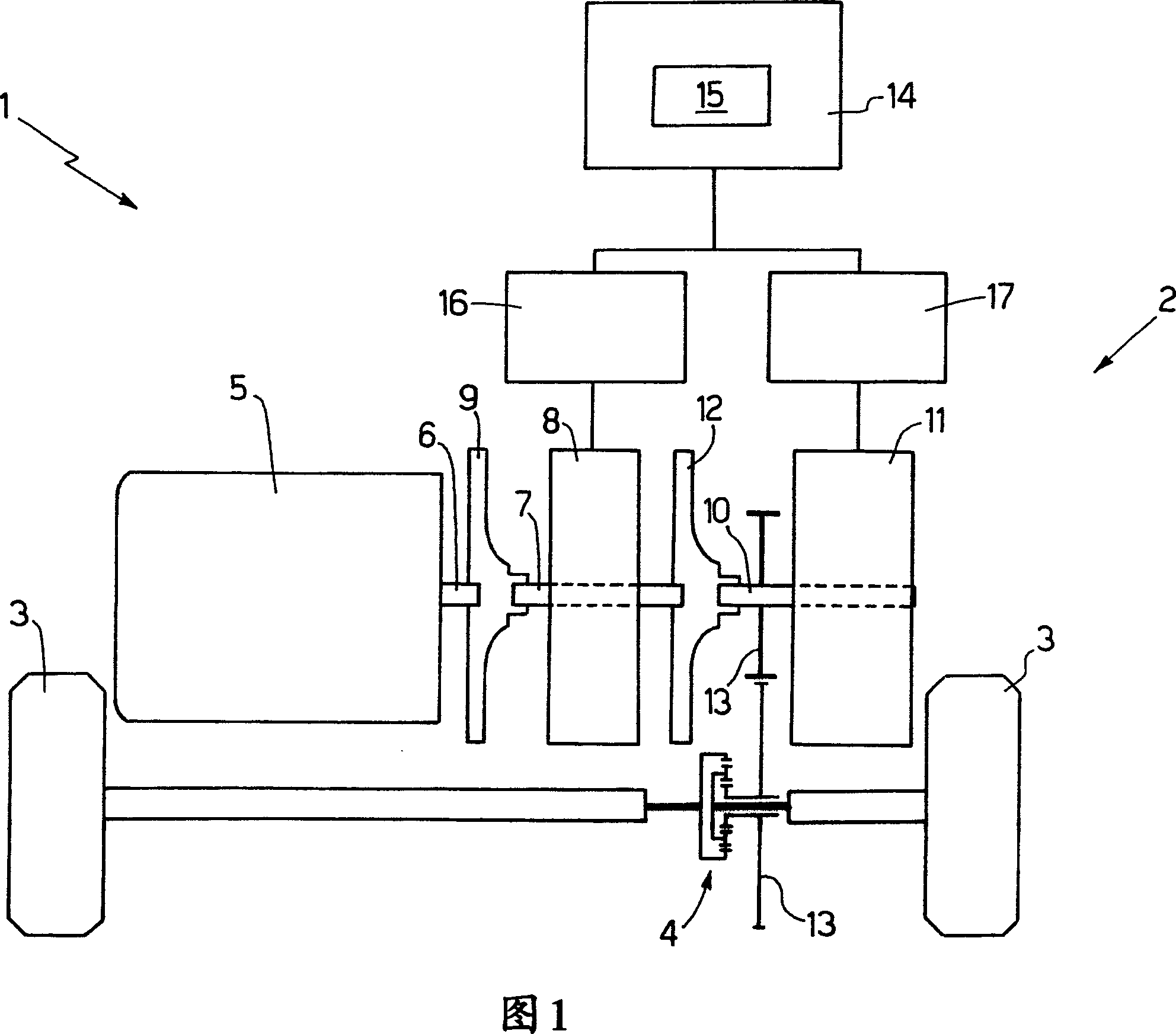

[0020] Numeral 1 in FIG. 1 designates a hybrid vehicle as a whole, which includes a transmission system 2 for applying drive torque to two drive wheels 3 via a differential 4 .

[0021] The transmission system 2 comprises a combustion engine 5 (in particular, an internal combustion engine or ICE) having a shaft 6 mechanically connected to the motor of a reversible electric motor generator (EMG) 8 via a decoupling system defined by a clutch (CL) 9 . Axis 7. Shaft 7 of reversible electric motor generator 8 is in turn mechanically connected to shaft 10 of reversible electric motor generator (EMG) 11 via a disconnect system defined by clutch 12 . In other words, the reversible electric motor generator 8 is located between the combustion generator 5 and the reversible electric motor generator 11 , one end of the shaft 7 of the reversible electric motor generator 8 is assembled on the clutch 9 , and the counter end is assembled on the clutch 12 .

[0022] The shaft 10 of the revers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com