Strip ribbon lap machine

A technology of sliver doubling machine and coiling machine, which is applied in the direction of coiling mechanism, spinning machine, textile and paper making, etc. It can solve the problems of large space occupied by the machine, repetitive and complicated mechanical structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

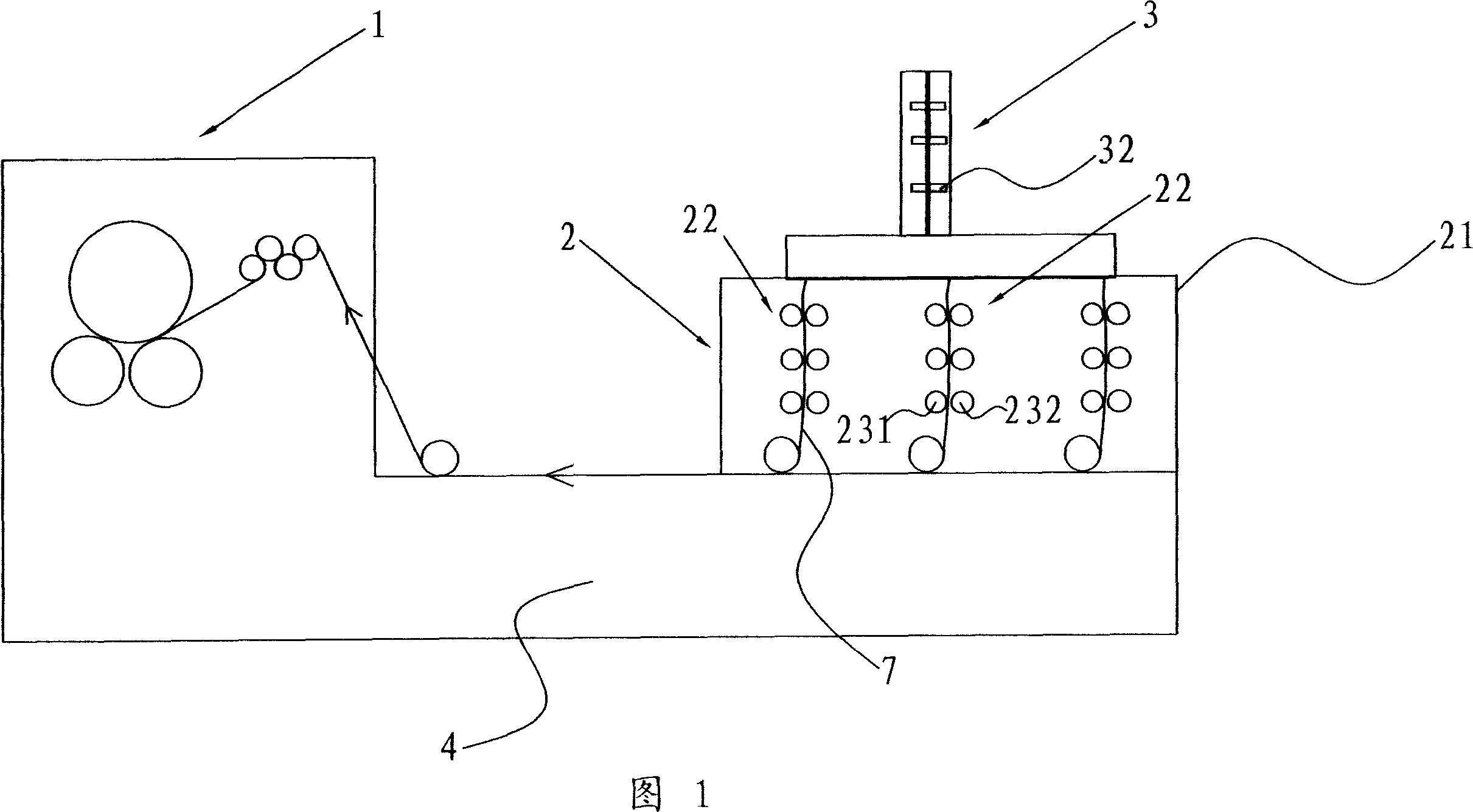

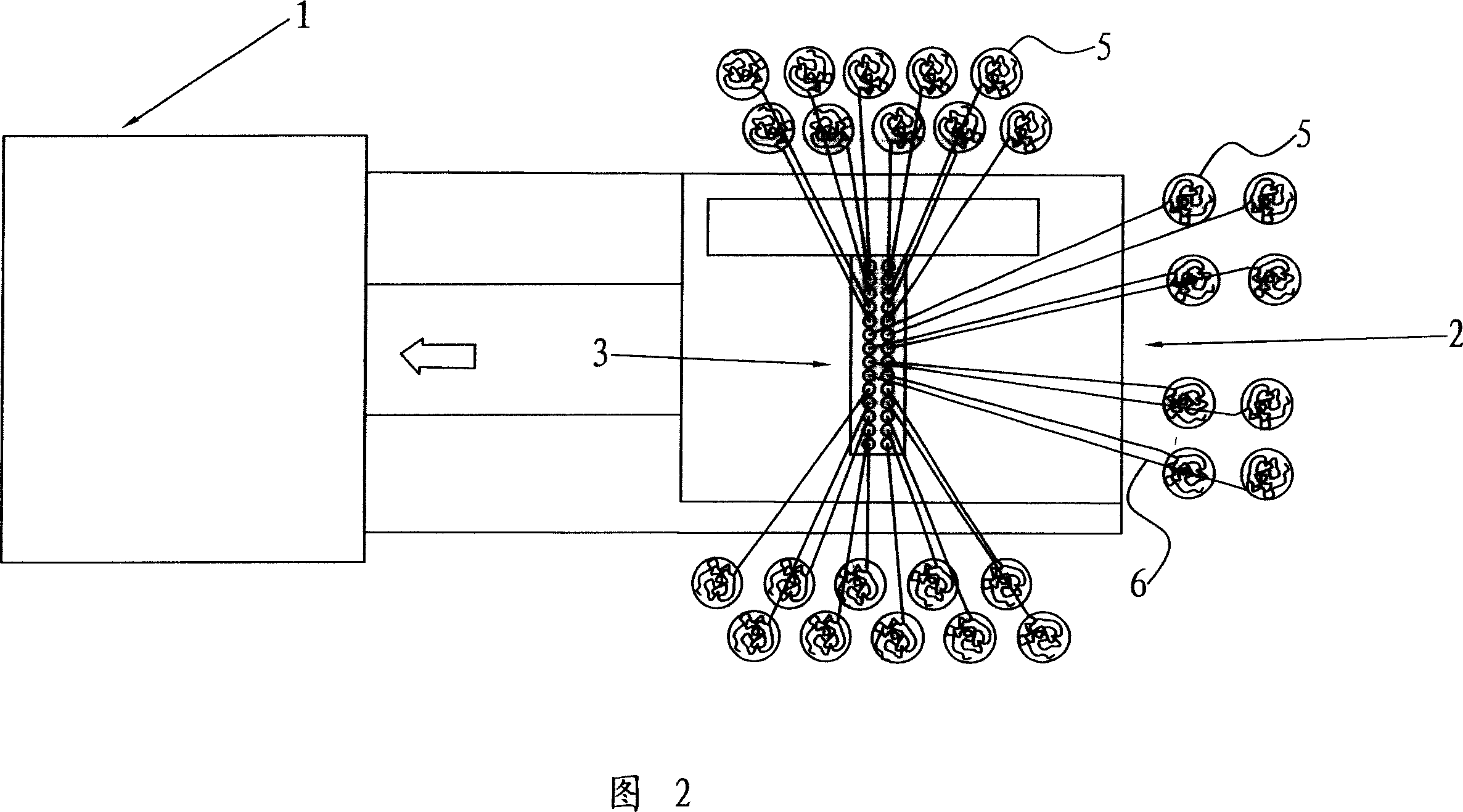

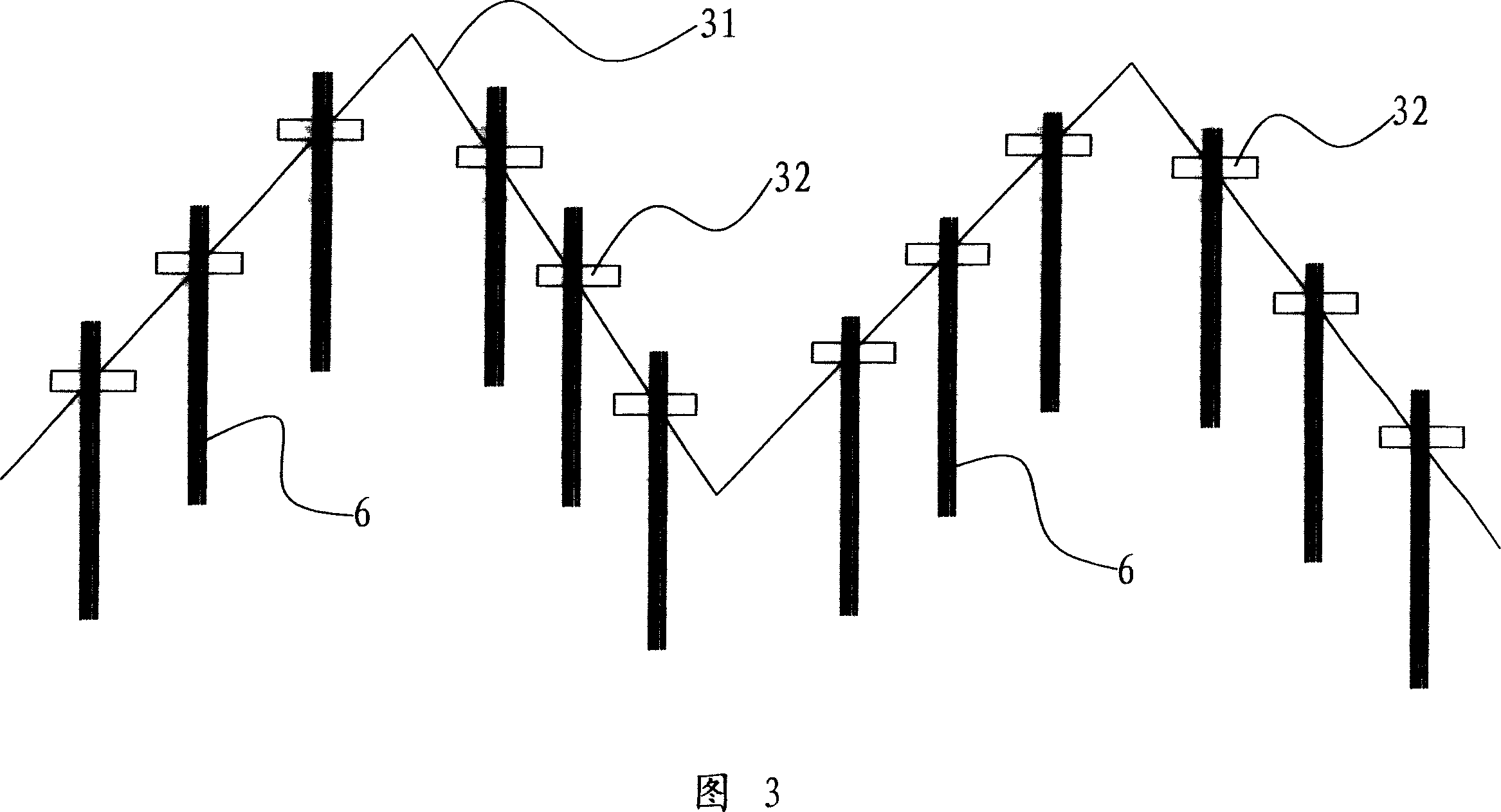

[0013] A kind of strip doubling machine shown in accompanying drawing 1-3, it comprises base 4, is arranged on described base 4 and is used for the combined drawing mechanism 2 that fiber strip 6 is combined stretching, uses In the lapping mechanism 1 that winds the fiber web 7 formed after the fiber sliver 6 is combined and stretched, the conveying direction of the fiber web 7 output by the combined drafting mechanism 2 and the winding of the lapping mechanism 1 The direction is the same, and a strip guide mechanism 3 for guiding the movement of the fiber strip 6 is arranged above the combined drafting mechanism 2, and the combined drafting mechanism 2 includes a top fixed on the base 4 Combining the drafting frame 21, at least two groups of merging drafting units 22 are arranged side by side in the combined drafting frame 21, and the described parallel arrangement refers to the The movement direction of the fiber web 7 between the mechanisms 2 is arranged front and rear, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com