Soft soil filling bag embankment back pressure consolidating method

A curing method and bag-filling technology, which can be used in dikes, buildings, soil protection, etc., can solve the problem of high cost, and achieve the effect of short reinforcement time, good consolidation effect and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

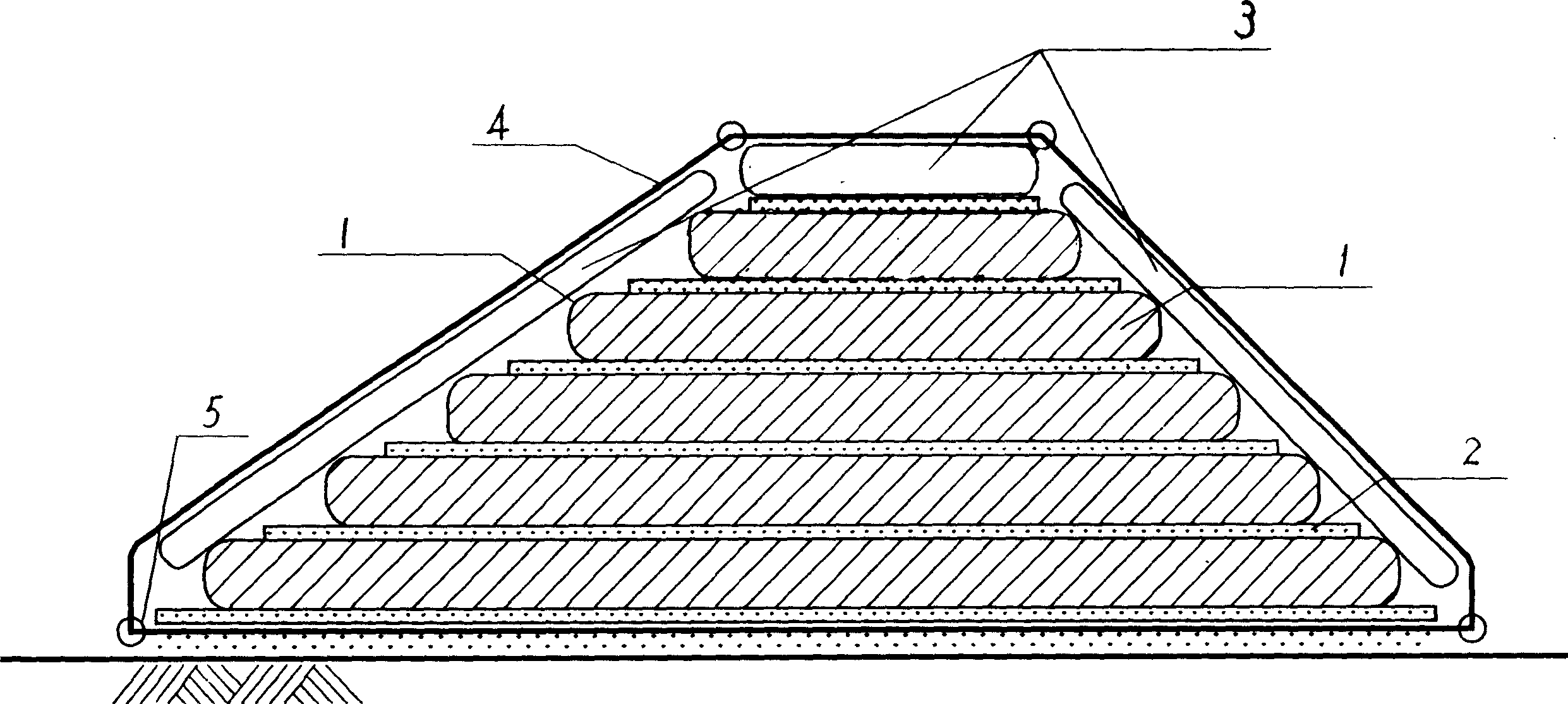

[0007] The present invention adopts the geotextile with good water permeability as the bag cloth of the upper and lower layers of the filling bag, so that the water between the silt soft soil layer 1 and the drainage filter layer 2 is smooth, and the filling thickness of the silt soft soil filled with the woven geotextile bag is 50cm-100cm; Layer 2 is filled with woven geotextile bags or composite geotextile bags with fine and silt sand, or horizontal drainage boards are used to facilitate the rapid drainage of water in the soil. The woven geotextile bags or composite geotextile bags are filled with fine and silt sand with a thickness of 10-20cm Left and right; a layer of silt soft soil, a layer of sand cushion or horizontal drainage boards are stacked alternately until the top elevation of the filling bag reaches the design level; the bag body of the silt soft soil layer and the drainage sand cushion can also be seamed in a multi-layer bag Make and sew two layers of bags, that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com