Seal ring on cover plate component, cover plate component, upper cover component and electric appliance

A technology of sealing ring and cover plate, which is applied to cooking utensil lids, pressure cookers, etc., can solve problems such as condensation of condensate water and affect the effect of customer experience, and achieve the effect of good sealing effect, good customer experience effect and compact electrical structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

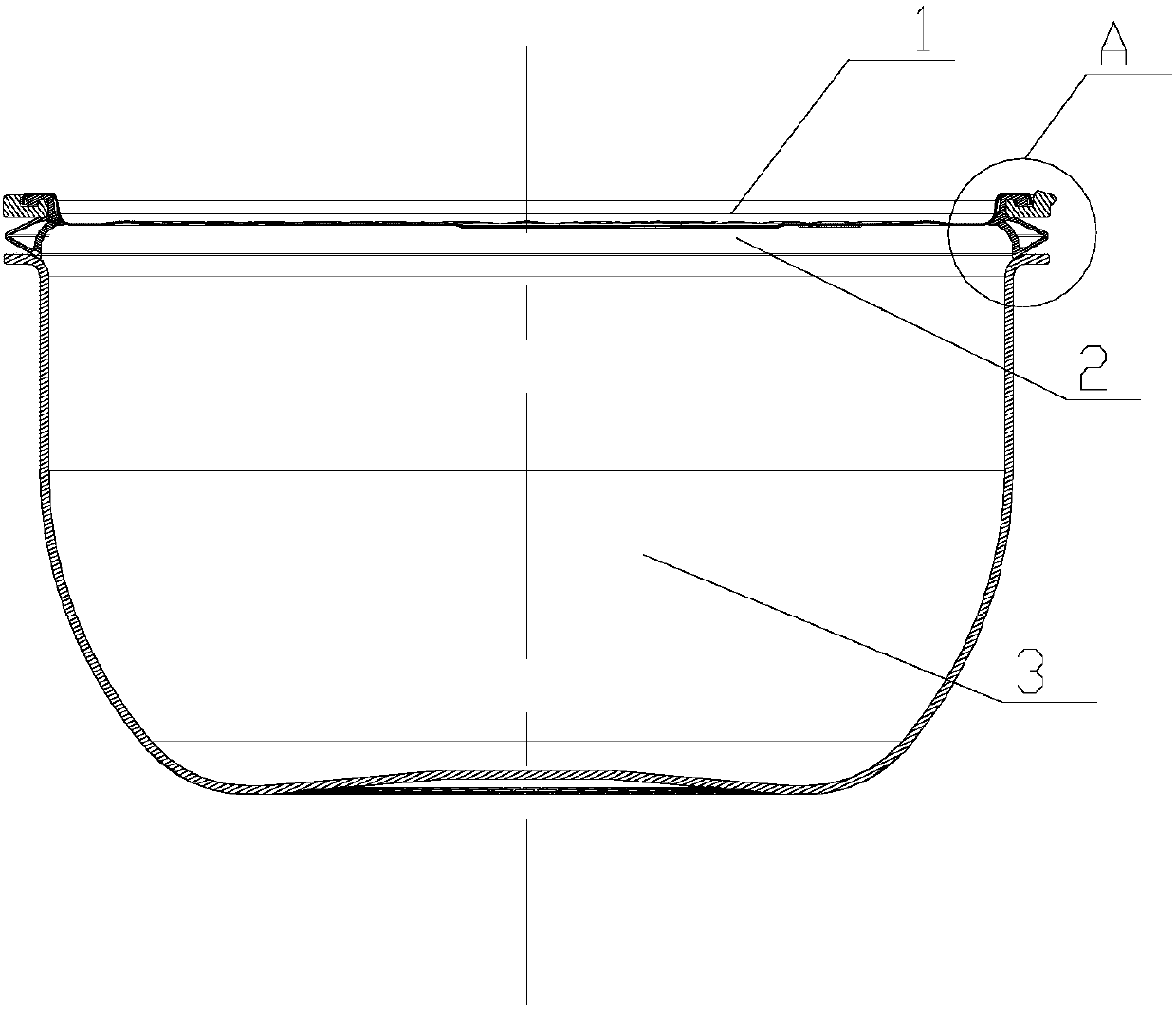

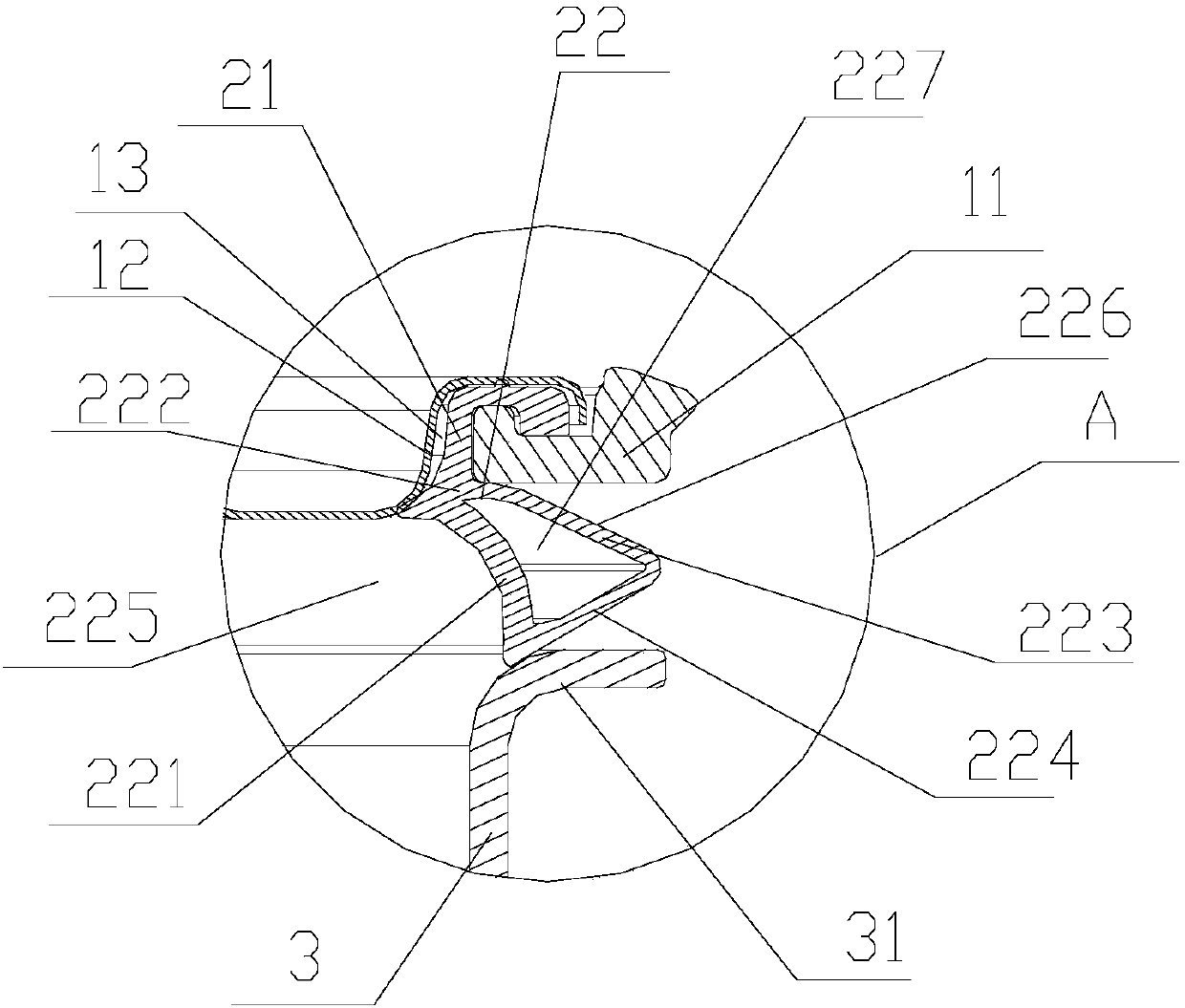

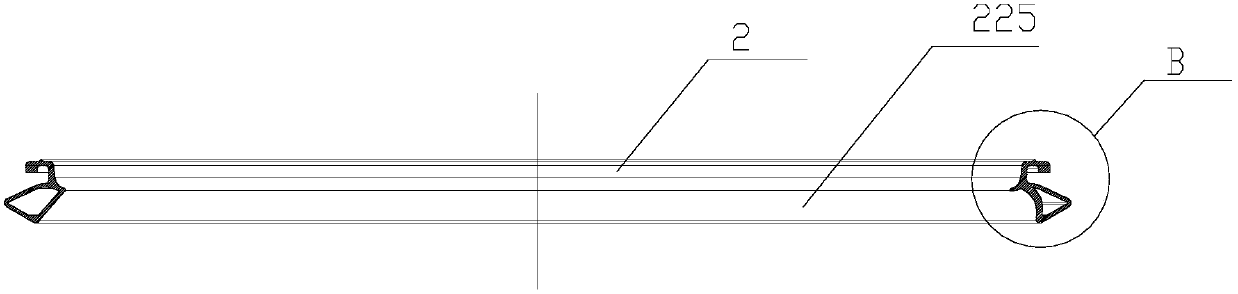

[0043] Such as Figure 1 ~ Figure 4As shown, the sealing ring on a cover plate assembly of this embodiment includes an integrally connected installation part 21 and a sealing part 22. On one side of the assembly 1 , the sealing portion 22 extends from one side of the cover assembly 1 in a direction away from the cover assembly 1 ; when the cover assembly 1 is fastened on the cooking vessel 3 The sealing part 22 abuts on the open edge 31 of the cooking vessel 3 and one side of the sealing part 22 located in the cooking vessel 3 is a water diversion arc surface 225, and the water diversion arc surface 225 is far away from the cover plate assembly 1 is located directly below or outside the end close to the cover plate assembly 1, that is, the vertical distance between the end of the water diversion arc 225 away from the cover plate assembly 1 and the central axis of the sealing ring 2 is greater than or equal to the water diversion arc 225 is the vertical distance between the en...

Embodiment 2

[0060] A cover plate assembly 1 of this embodiment, such as figure 1 and figure 2 As shown, the cover plate assembly 1 includes a cover plate body 12, a ring-shaped pressure plate 11 and a sealing ring 2 as described in Embodiment 1, and the pressure plate 11 is crimped on the peripheral edge of the cover plate body 12 And an annular gap 13 is formed between the cover plate body 12, the mounting part 21 is sealed and crimped in the annular gap 13 and is located on the inner ring side of the pressure plate 11, and the longitudinal section is "Γ" shaped The mounting part 21 is crimped in the annular gap 13, so that the clamping between the mounting part 21 and the pressure plate 11 is firmer; the sealing part 22 extends from the annular gap 13 in a direction away from the cover plate assembly 1 and the annular The gap 13 is sealed and covered. In this embodiment, when the sealing ring abuts against the open edge of the cooking vessel, the side of the sealing ring located in t...

Embodiment 3

[0062] This embodiment provides an upper cover assembly, including a cover body and the cover assembly 1 as described in Embodiment 2, and the other side of the cover assembly 1 is connected to the cover body. The upper cover assembly of this embodiment has a good sealing effect, which facilitates the condensed water to slide out from the sealing ring, keeps the sealing ring in an anhydrous state, and avoids water accumulation inside the sealing ring due to steam condensation during the cooking process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com