Vertical steam boiler

A steam boiler, vertical technology, applied in steam boilers, fire tube steam boilers, water tube steam boilers, etc., can solve the problems of unreasonable heat exchange cycle process, reduced safety and service life, and high utilization rate of heat energy absorption , to achieve the effect of reasonable heat exchange cycle process, long service life and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

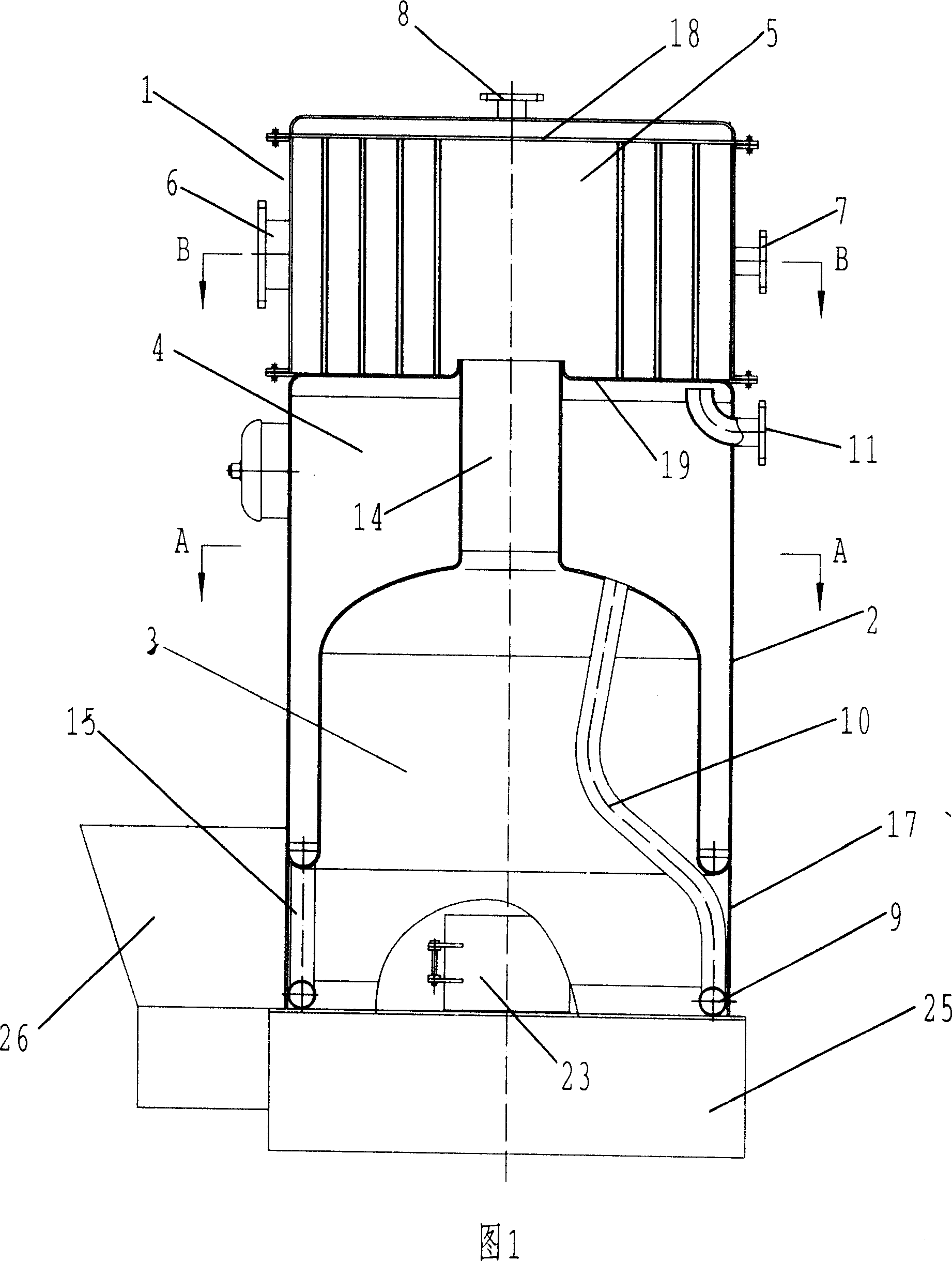

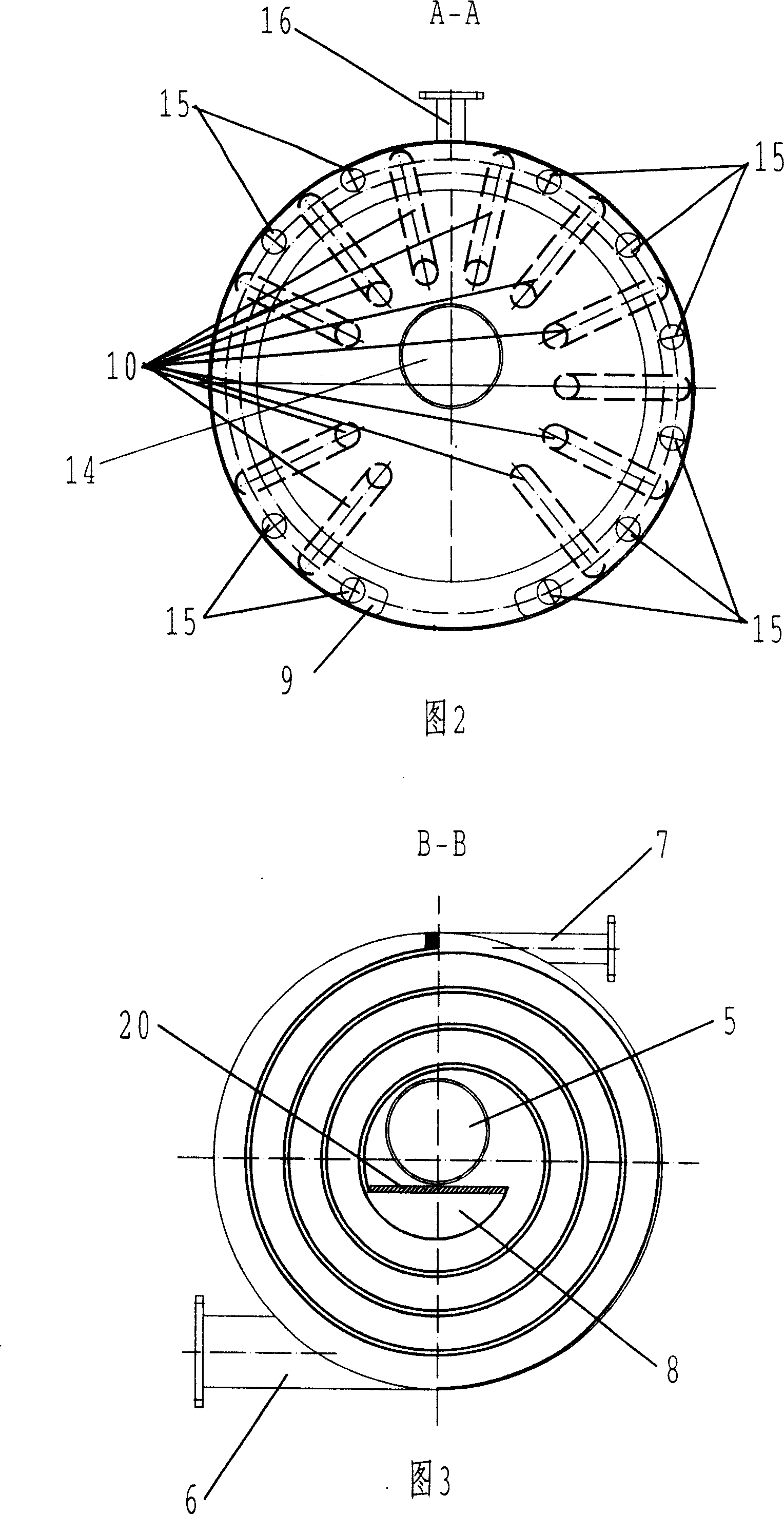

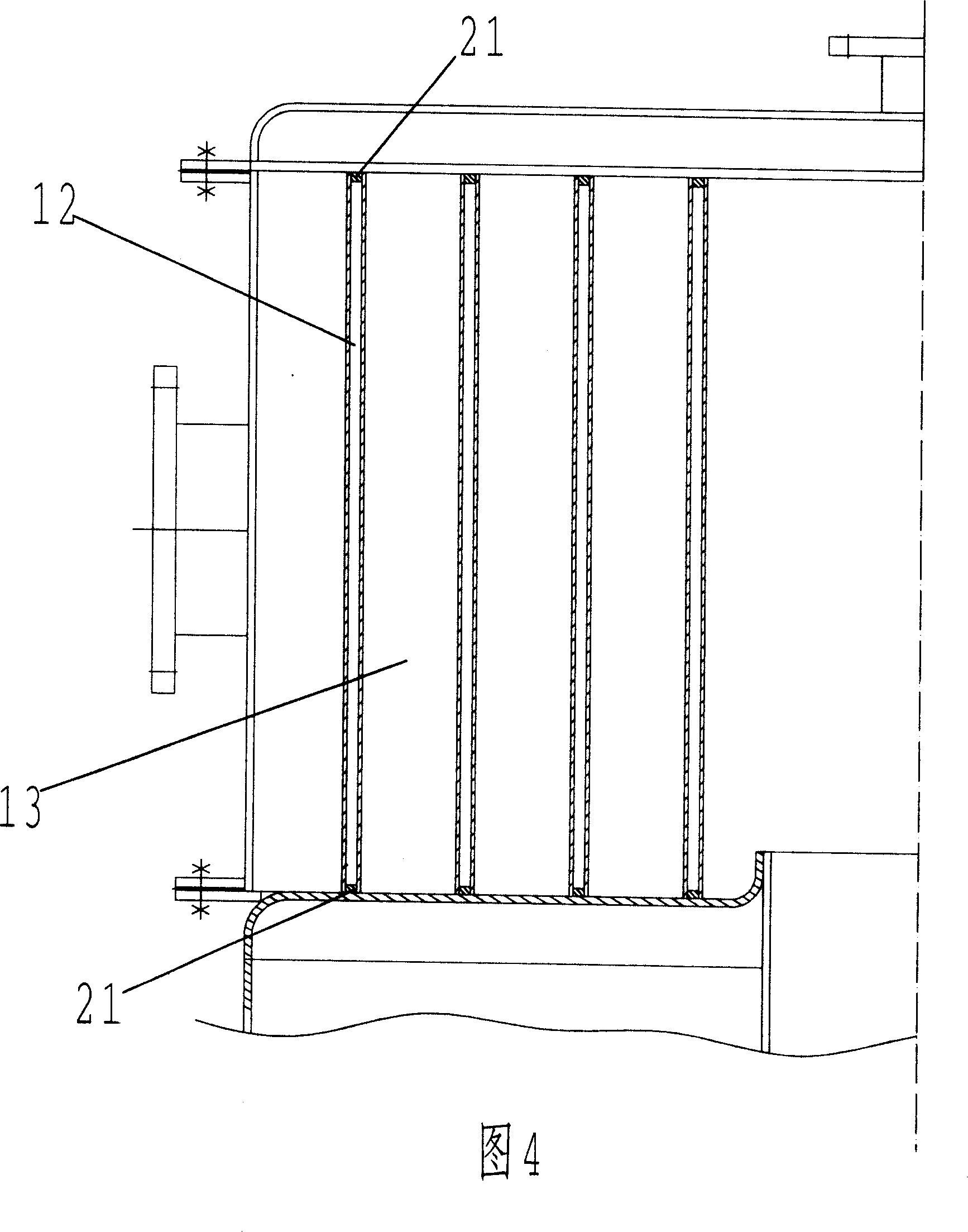

[0022] See Figures 1, 3, and 4. The spiral heat exchanger 1 is composed of a spiral sandwich body in the middle, an upper cover plate 18, and a lower bottom plate 19. The upper cover plate 18 is composed of a thin plate and an insulation layer. The spiral interlayer cavity is a spiral water channel 12, and the spiral gap between the spiral interlayers is a spiral In the flue 13, the primary hot water enters through the spiral channel inlet 7 at the outer spiral end and flows out through the central spiral channel outlet 8, and the high-temperature flue gas enters through the central spiral flue inlet 5 and is discharged from the spiral flue outlet 6 at the outer spiral end. The upper and lower ends of the spiral interlayer cavity have spiral strip sealing plates 21 to form a welded closed interlayer body. The upper and lower ends of the spiral flue 13 are in close contact with the upper cover plate 18 and the lower bottom plate 19, and no spiral strip sealing plates are provide...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap