Ultra-high voltage compound brace insulator

A pillar insulator and UHV technology, applied in the field of UHV composite pillar insulator, can solve the problems of complex production process, high electrical and mechanical performance requirements, and high voltage level, and achieve high strength, excellent pollution resistance, and short production cycle. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

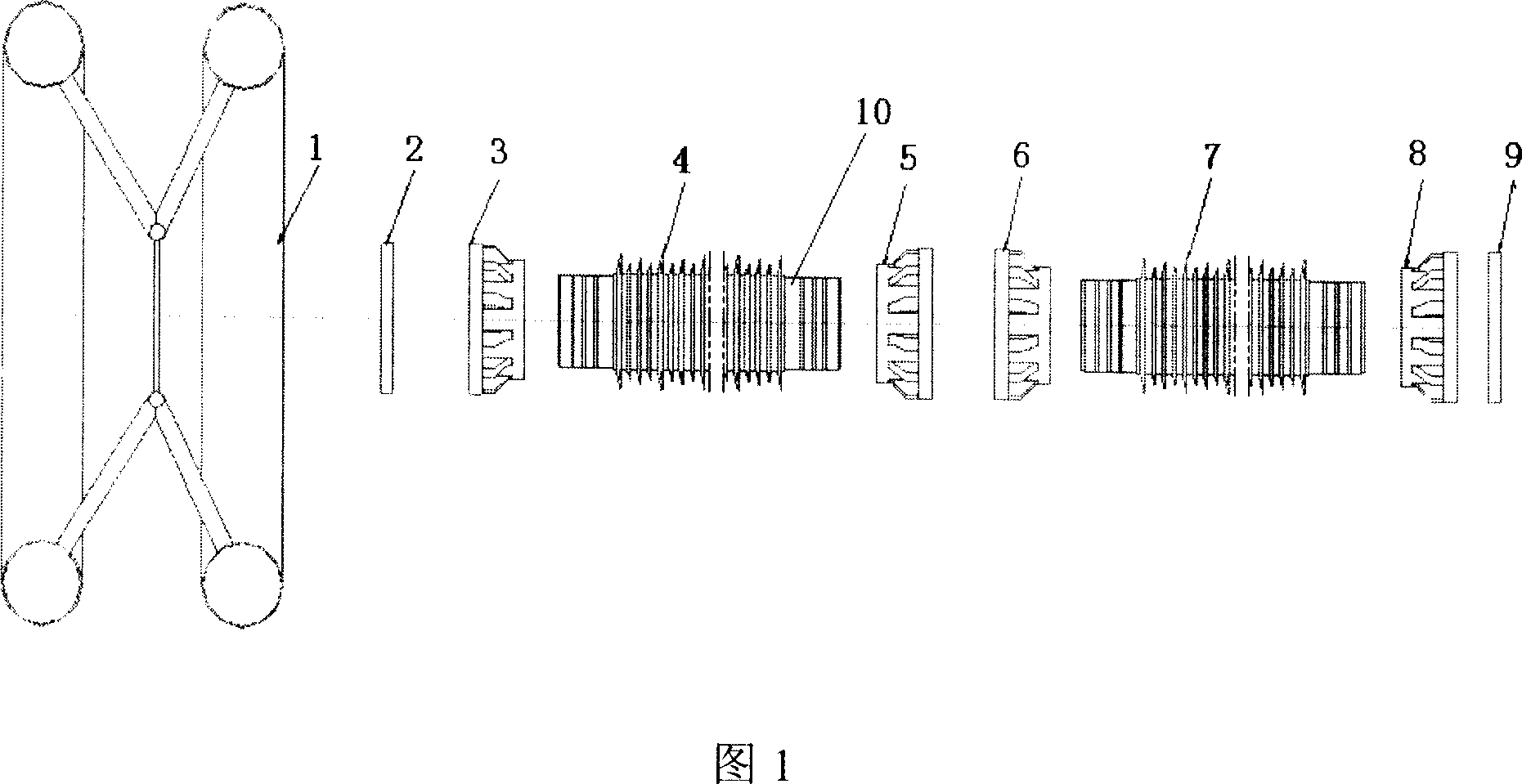

[0019] As shown in Figure 1, the UHV composite post insulator of the present invention is divided into upper and lower sections with the same structural height. From top to bottom, there are shielding ring 1, upper sealing plate 2, upper end flange 3, and upper section shed skirt. Sleeve 4, middle upper flange 5, middle lower flange 6, lower section sheath sheath 7, bottom flange 8, lower sealing plate 9, inside the shed sheath is a core body 10 divided into two parts, the core body It is connected as a whole by the middle upper flange 5 and the middle lower flange 6 .

[0020] The shielding ring 1 with a unique double-ring structure not only improves the overall electric field distribution of the insulator, but also plays a shielding role for the wire connecting fittings, greatly reducing the level of radio interference. The upper end flange 3 is installed to connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com