Method for weighing a product, weighing system and loading device

A weighing system and weighing device technology, applied in the direction of measuring devices, weighing equipment for continuous material flow, weighing, etc., can solve problems such as manipulation and misadjustment, and achieve the effect of improving error control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

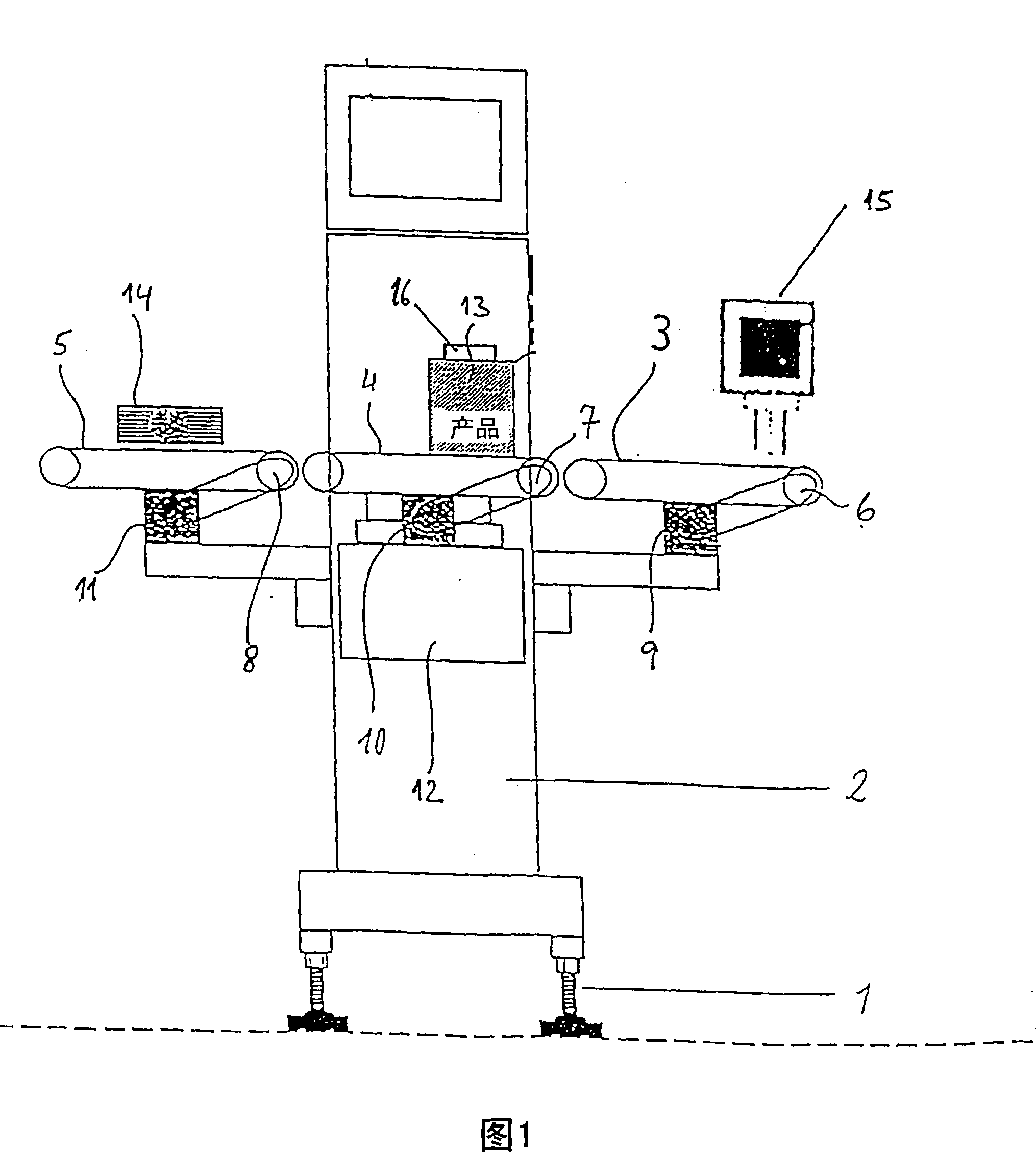

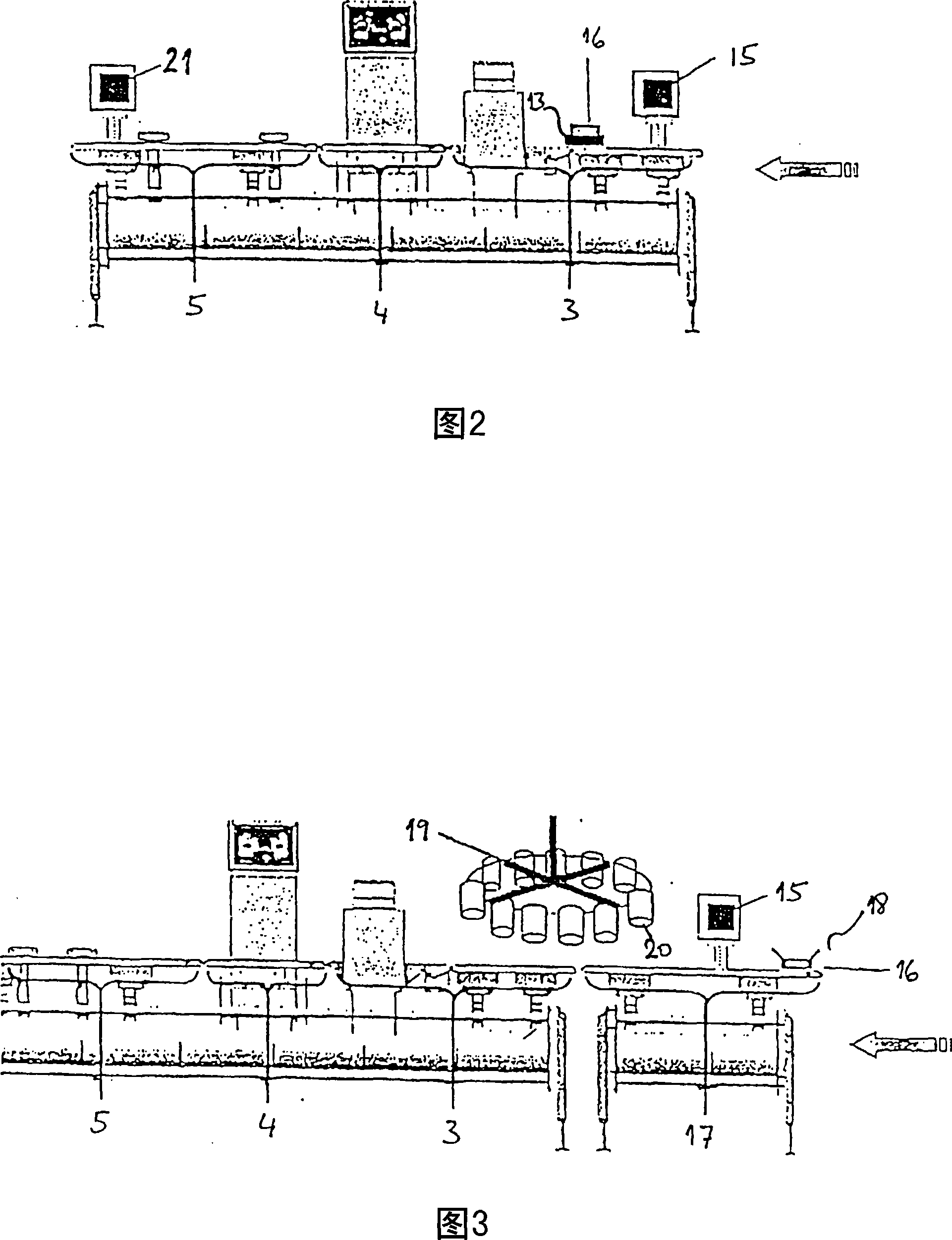

[0033] The embodiment of the weighing system represented schematically in Figure 1 shows a basic frame 2 with adjustable height supporting feet 1 standing on the floor, on which a conveyor belt 3 is fed, acting as a measurement line The weighing conveyor belt 4 and the unloading conveyor belt 5 are continuously arranged in a horizontal alignment. The three conveyor belts 3, 4 and 5 are directed in the same direction and circulate at the same speed on two horizontally spaced rollers, each of which, namely rollers 6, 7 and 8, is driven by a motor 9, 10 and 11 respectively drive. These motors are controlled so that the same belt speed setting can be guaranteed for all three belts 3 , 4 and 5 .

[0034] A weighing conveyor 4 serving as a measuring conveyor line is supported on a weighing cell 12 , which is fastened to the basic frame 2 . With respect to the transport direction at the infeed conveyor 3, the products to be weighed 13 are loaded one by one on the entry side on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com