Automatic temperature controlling device of gas kitchen range

An automatic temperature control and gas stove technology, applied in the field of stoves, can solve the problems of affecting the normal use of gas stoves, inaccurate temperature of temperature control switches, etc., and achieve the effects of accurate detection of pot bottom temperature, simple structure, and convenient manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

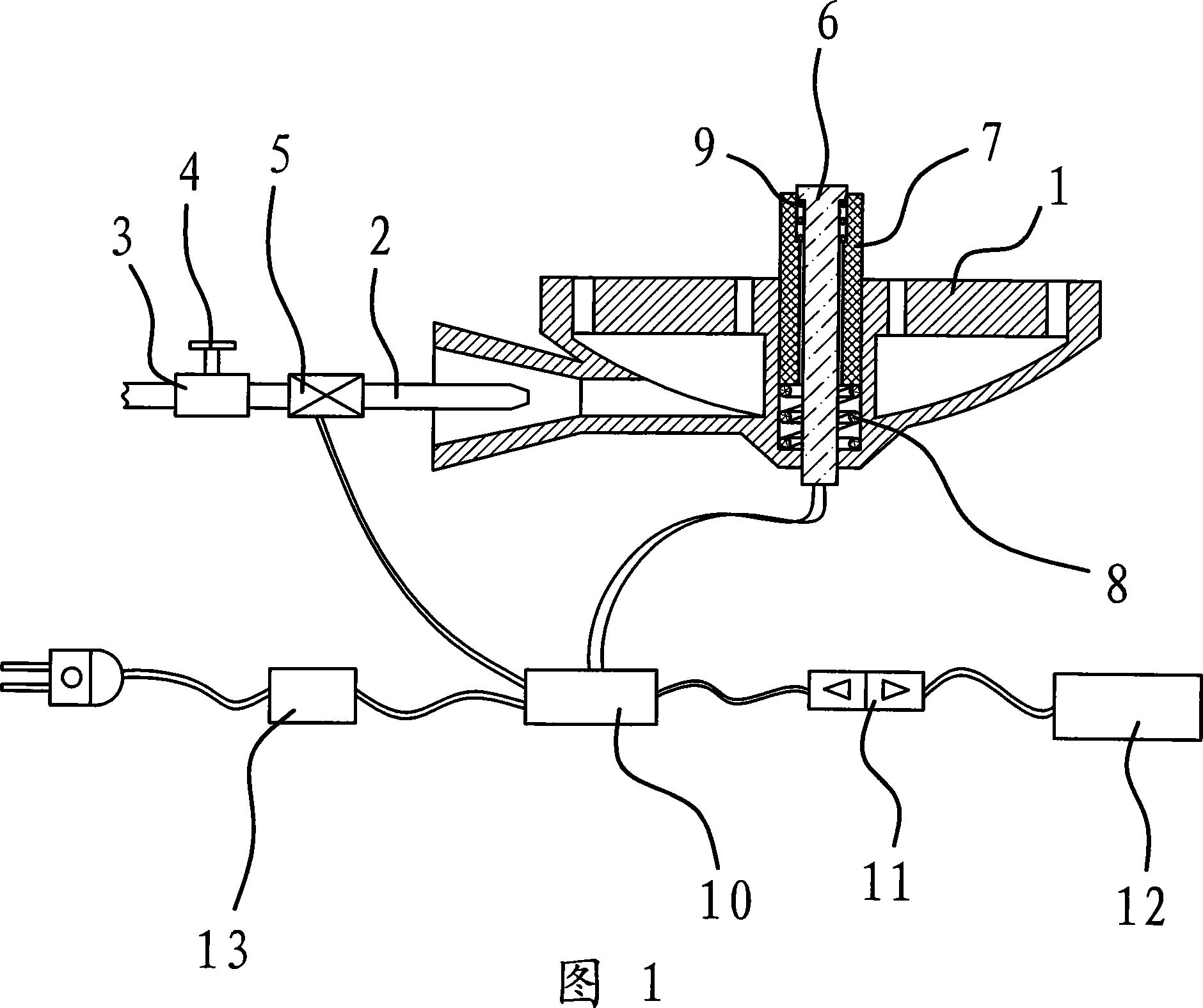

[0027] As shown in FIG. 1 , an air intake pipe 2 is connected to the gas cooker, and an air valve 4 and an igniter 3 are arranged on the air intake pipe 2 . Open the gas valve 4 and the gas can enter the burner 1 of the gas range through the intake pipe 2, and the gas at the burner 1 can be ignited by the igniter 3 simultaneously. The automatic temperature control device of the gas cooker is arranged at the burner 1 of the gas cooker, through which the amount of gas entering the burner 1 from the intake pipe 2 can be controlled, and finally the purpose of changing the firepower of the burner 1 can be achieved.

[0028] The automatic temperature control device of the gas cooker includes a solenoid valve 5, a control circuit and a temperature sensing probe 6. The electromagnetic valve 5 is arranged on the intake pipe 2, and the electromagnetic valve 5 is connected with the control circuit. The temperature-sensing probe 6 is connected to the control circuit. The outer side of th...

Embodiment 2

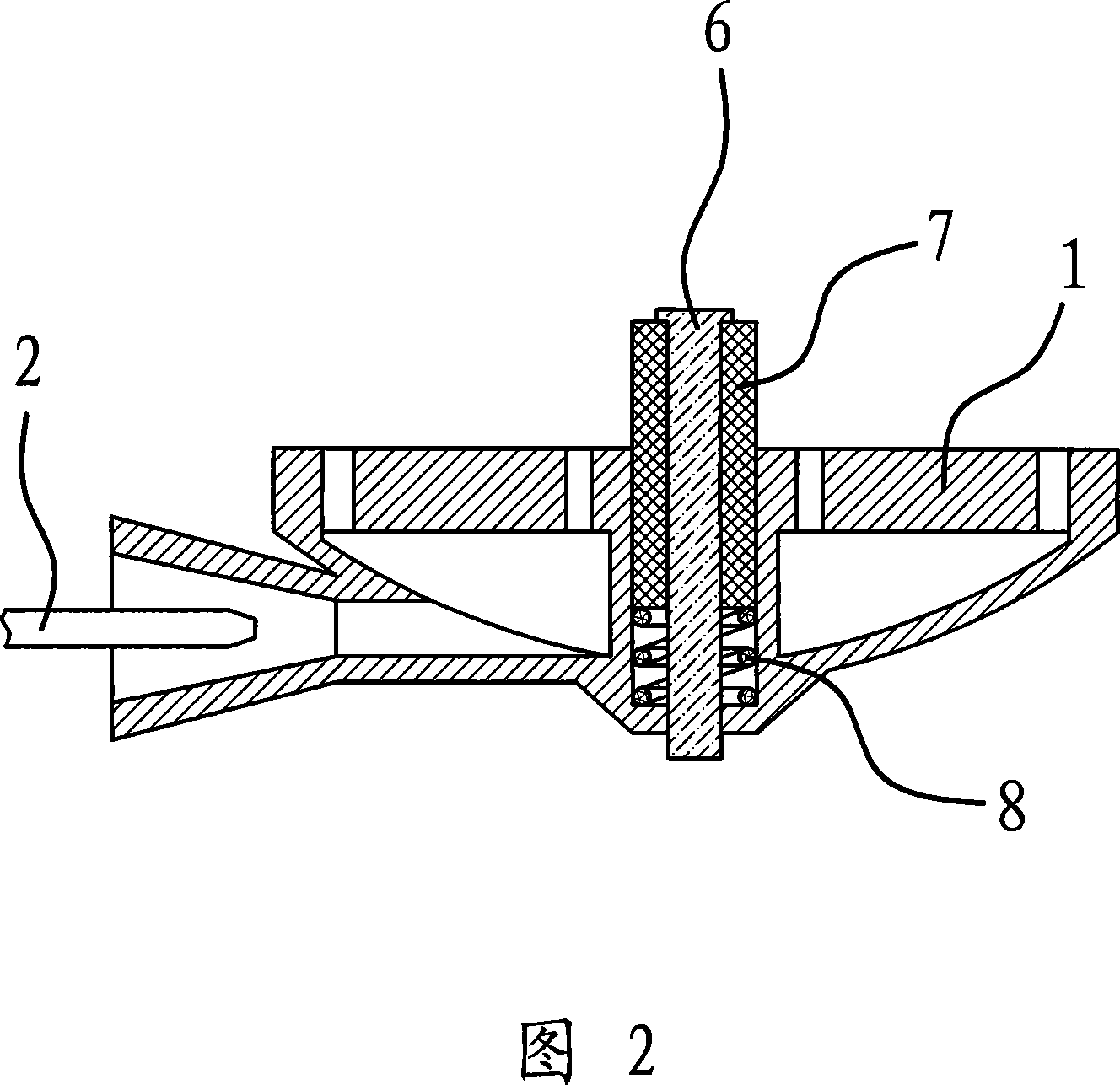

[0036] The structure and principle of this embodiment are basically the same as that of Embodiment 1. The difference is that the above-mentioned elastic mechanism is a spring 8 set on the lower part of the temperature probe 6, and the two ends of the spring 8 act on the temperature probe 6 and the burner 1 respectively. , and the above-mentioned heat-insulating sheath 7 is fixedly connected with the temperature-sensing probe 6, as shown in FIG. 2 . It can be seen that under the action of the spring 8, the heat-insulating sheath 7 and the temperature-sensing probe 6 will move upward together.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com