Printed circuit board processing device and drilling processing method therefor

A technology for printed circuit boards and processing equipment, applied in the directions of printed circuit, printed circuit manufacturing, metal processing equipment, etc., can solve the problems of no disclosure of movement control, the overall increase of drill drilling processing equipment, and no disclosure, etc. Body vibration, reduced rocking vibration, high-precision machining effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

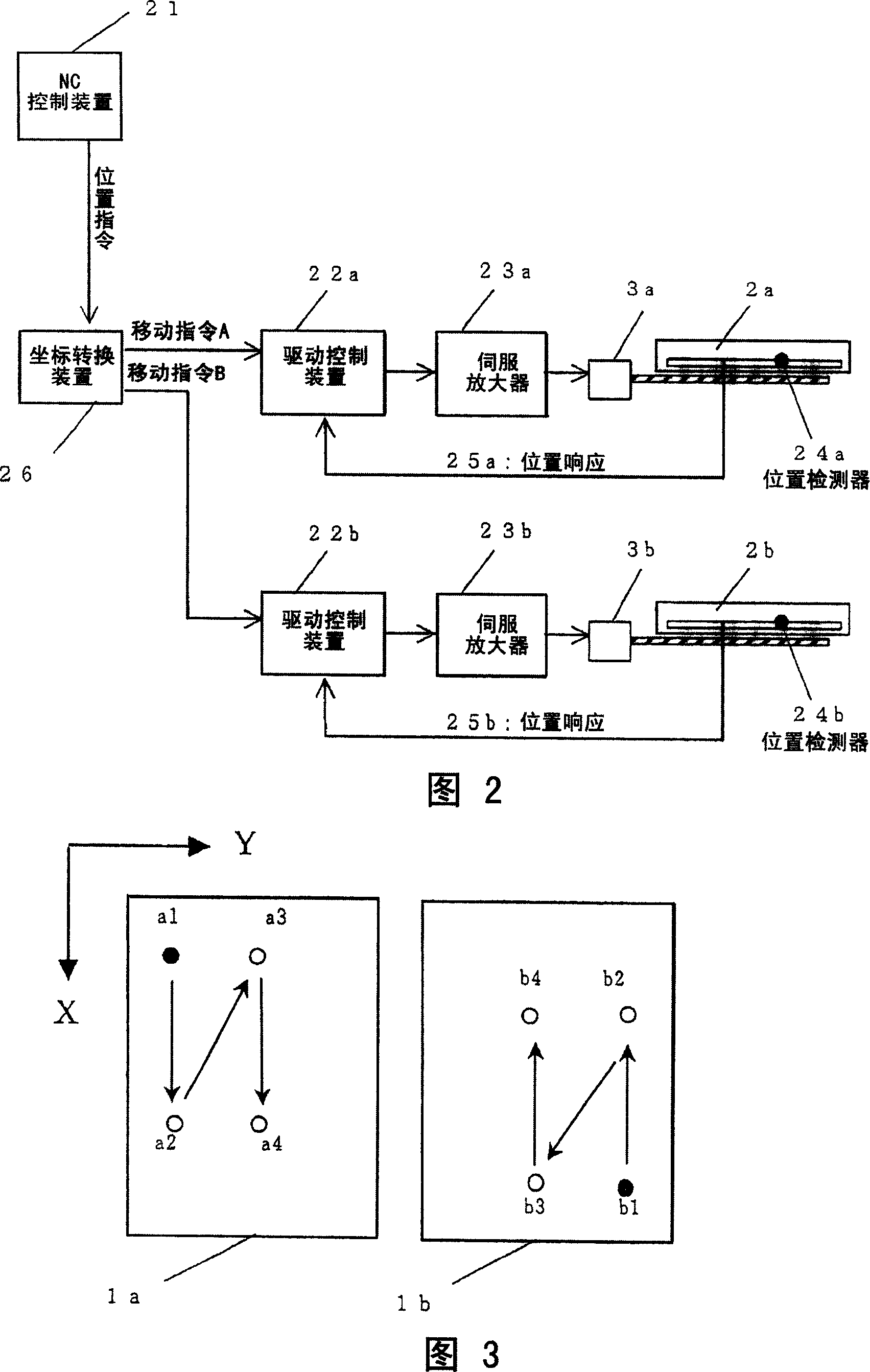

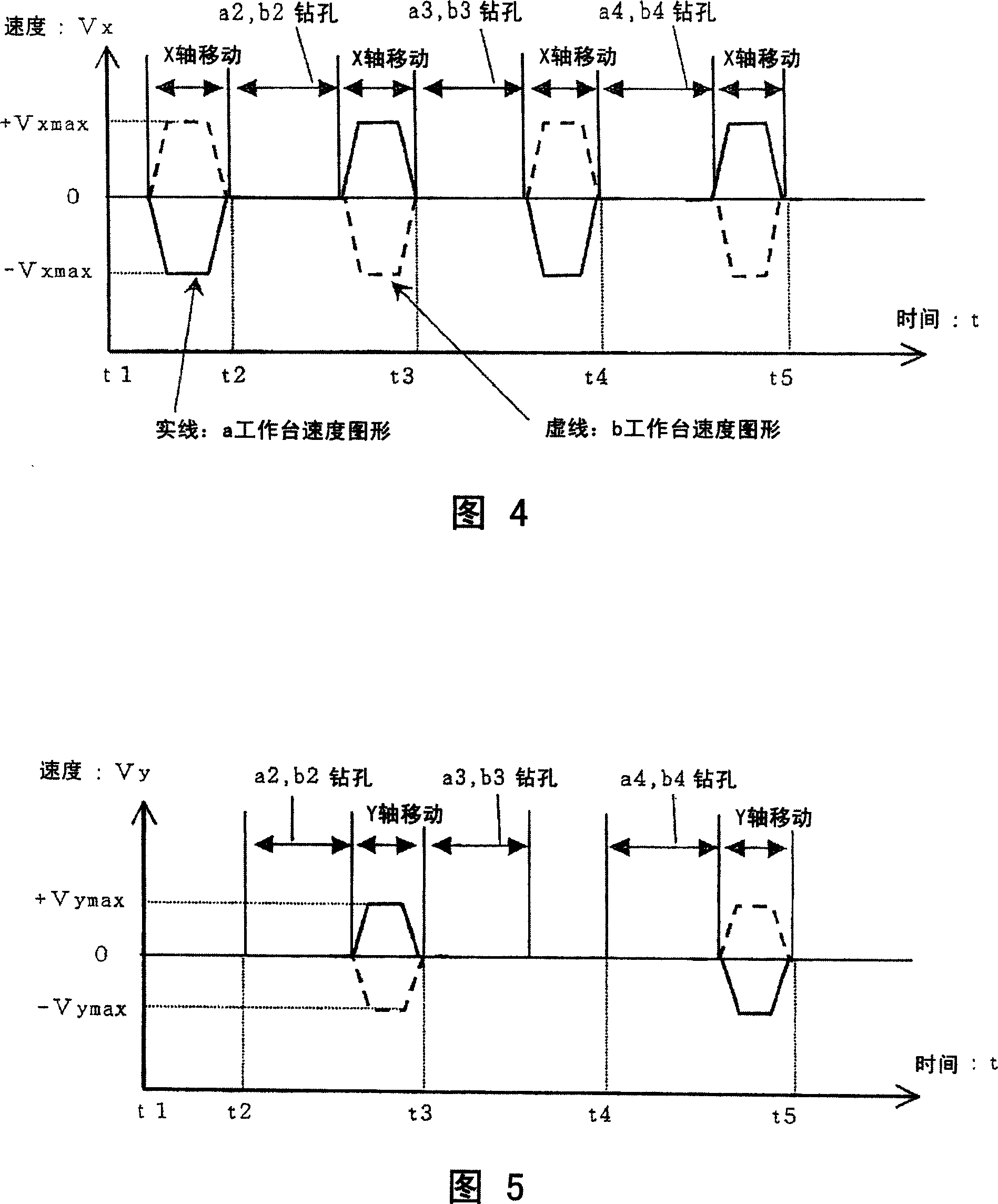

[0047] In the above-mentioned first embodiment, one of the two printed circuit boards is rotated 180° relative to the other and arranged on the table, and when the processing position is, for example, point-symmetrical or nearly point-symmetrical with respect to the center of the printed circuit board in the XY direction , as shown in FIG. 7, the directions of the printed circuit boards 1a and 1b loaded on the worktables 2a and 2b can also be set to be the same, as indicated by the arrows in the same drawing, and the processing order of the above-mentioned printed circuit boards adjacent to each other can be set to be the same. Instead, process it.

[0048] In addition, in the above-mentioned Embodiments 1 and 2, the case where the plurality of lateral sliding plates 8a, 8b are arranged on one side of the column body 9 (the front side in FIG. 1 ) was described, but it may be arranged as follows.

Embodiment 3

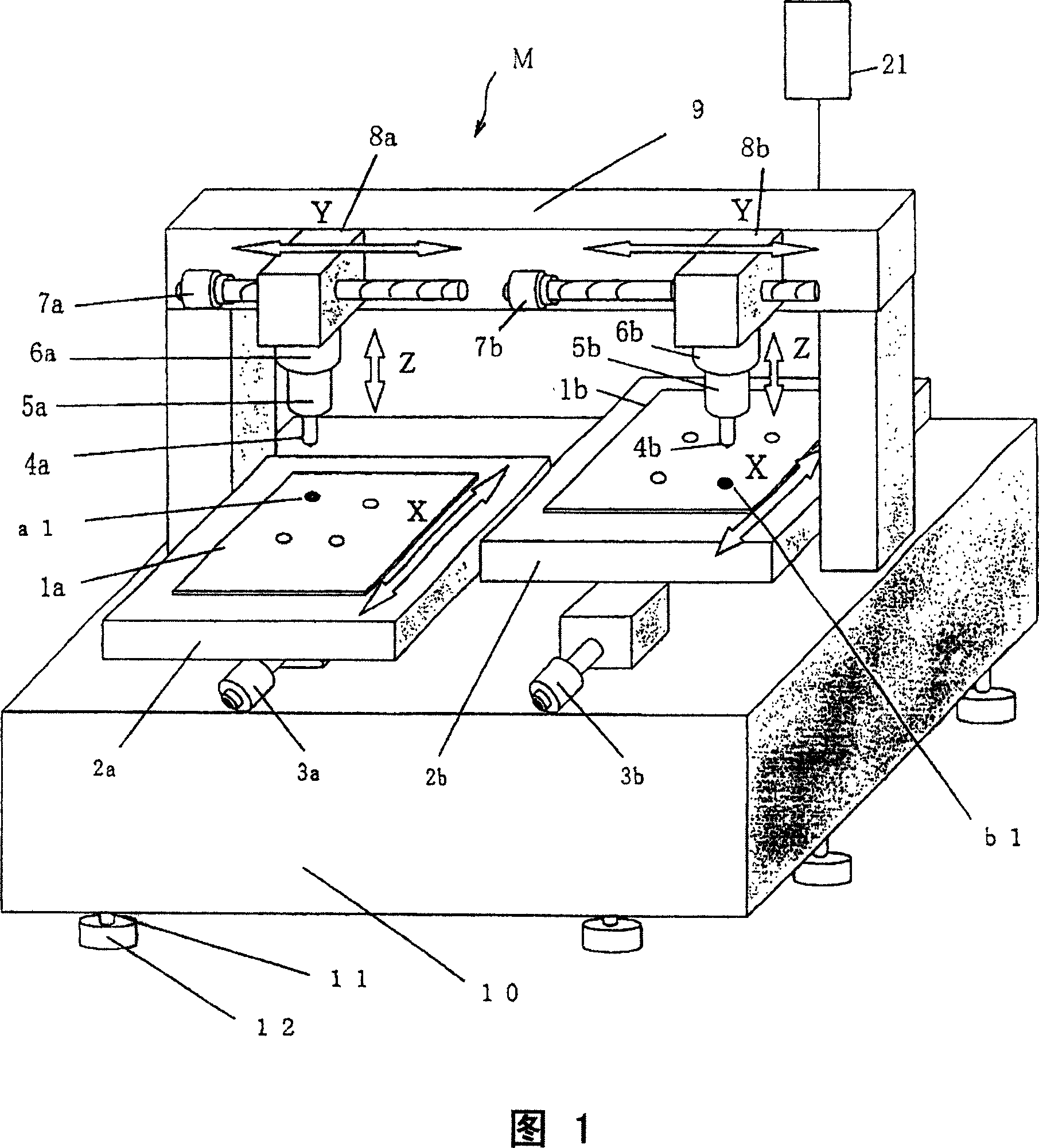

[0050] 8 is a plan view showing the structure of another printed circuit board processing equipment to which the present invention is applied, and the same components or components with the same functions as those in FIG. 1 are assigned the same reference numerals and description thereof will be omitted.

[0051] As shown in the same figure, this printed circuit board processing facility includes not only tables 2a, 2b and lateral slides 8a, 8b shown in FIG. 1 but also tables 2c, 2d, and lateral slides 8c, 8d.

[0052] The table 2c and the table 2a, and the table 2d and the table 2b are arranged on the bed 10 so that the moving direction of the center of gravity is coaxial. Tables 2c and 2d are freely movable in the front-back (X) direction by linear guides (not shown) and X-axis drive devices 3c and 3d. Printed circuit boards 1c, 1d are respectively arranged on workbenches 2c, 2d. In addition, the printed circuit board 1c is rotated by 180° relative to the printed circuit bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com