Method and device for compressing a gaseous medium

A technology for compressing gas and gas media, applied in pressure pumps, petroleum industry, machines/engines, etc., can solve problems such as high production and maintenance costs, achieve the effect of prolonging service life and avoiding safety problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

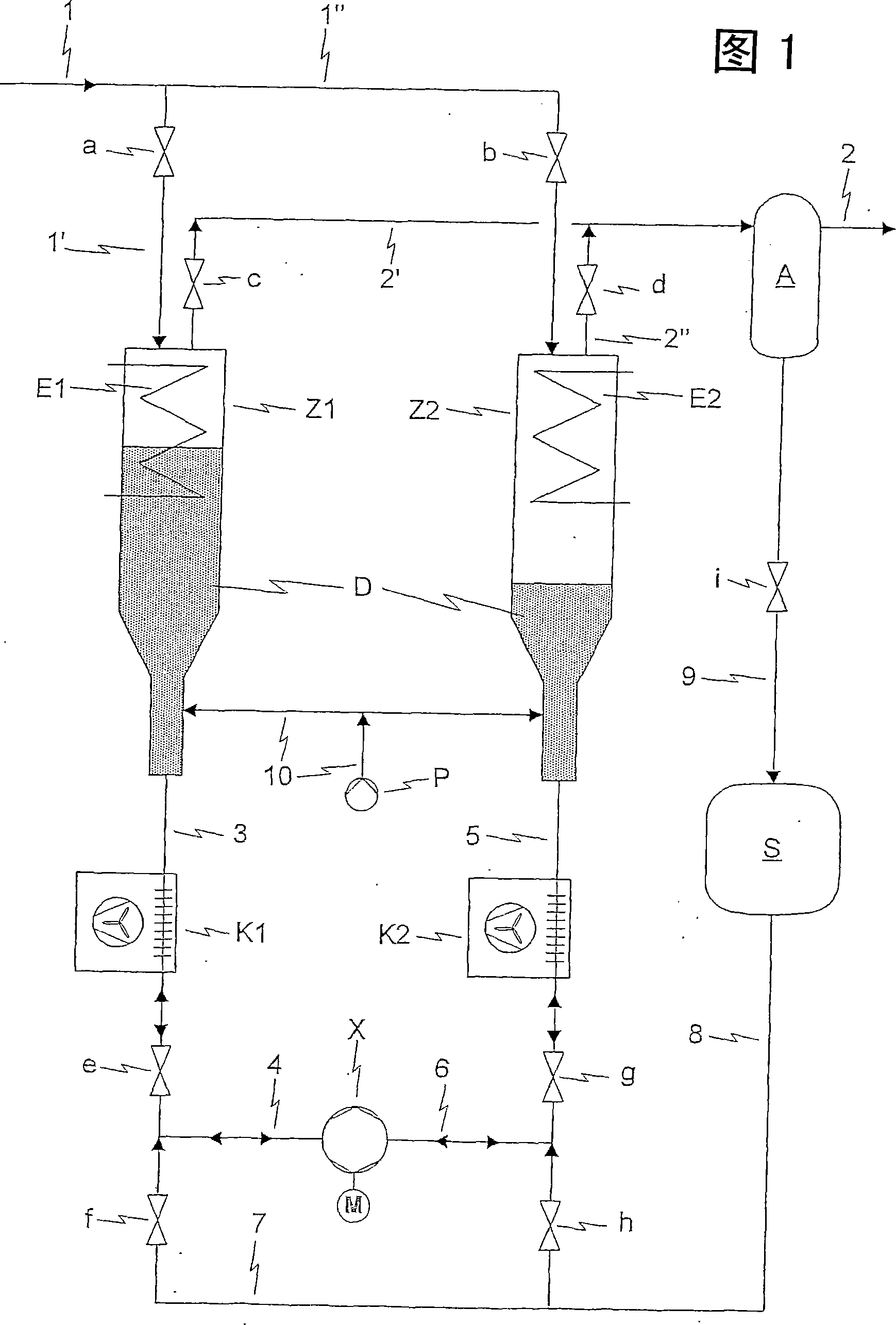

[0026] The gaseous medium to be compressed is conveyed to the cylinders Z1 and Z2 via the pipes 1, 1' and 1". In the above-mentioned pipes, the inlet valves a and b are arranged. After the compression is completed, the compressed gaseous medium is passed from the cylinders Z1 and Z2 through the discharge pipes 2' and 2" are discharged, valves c and d are likewise provided in the discharge pipe.

[0027] The compressed gaseous medium is separated in a separating device A from any liquid entrained from the cylinders Z1 and Z2 , which will be described in more detail below, and is then conveyed via line 2 to its further use and / or intermediate storage.

[0028] A suitable liquid D for compressing the gaseous medium is arranged inside the cylinders Z1 and Z2. Cylinders Z1 and Z2 are connected via lines 3 to 6 and a hydraulic pump X driven by an electric motor M.

[0029] The fluid levels in the cylinders Z1 and Z2 are varied by means of the hydraulic pump X in such a way that one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com