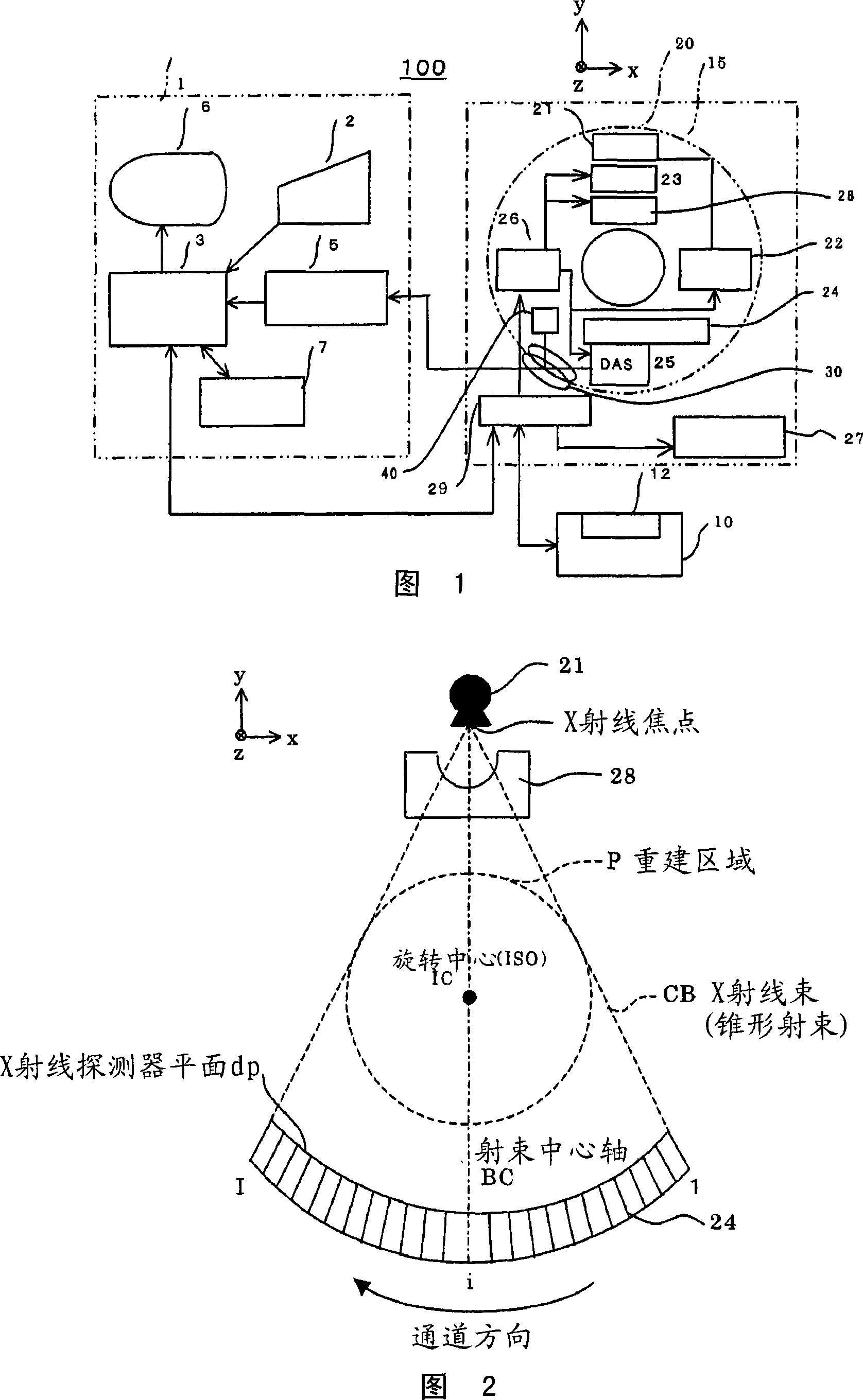

X-ray CT imaging method and X-ray CT apparatus

A technology for X-ray and image display devices, which is used in measurement devices, instruments for radiological diagnosis, and material analysis using radiation, which can solve problems such as manufacturing difficulties and achieve high-resolution effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 2

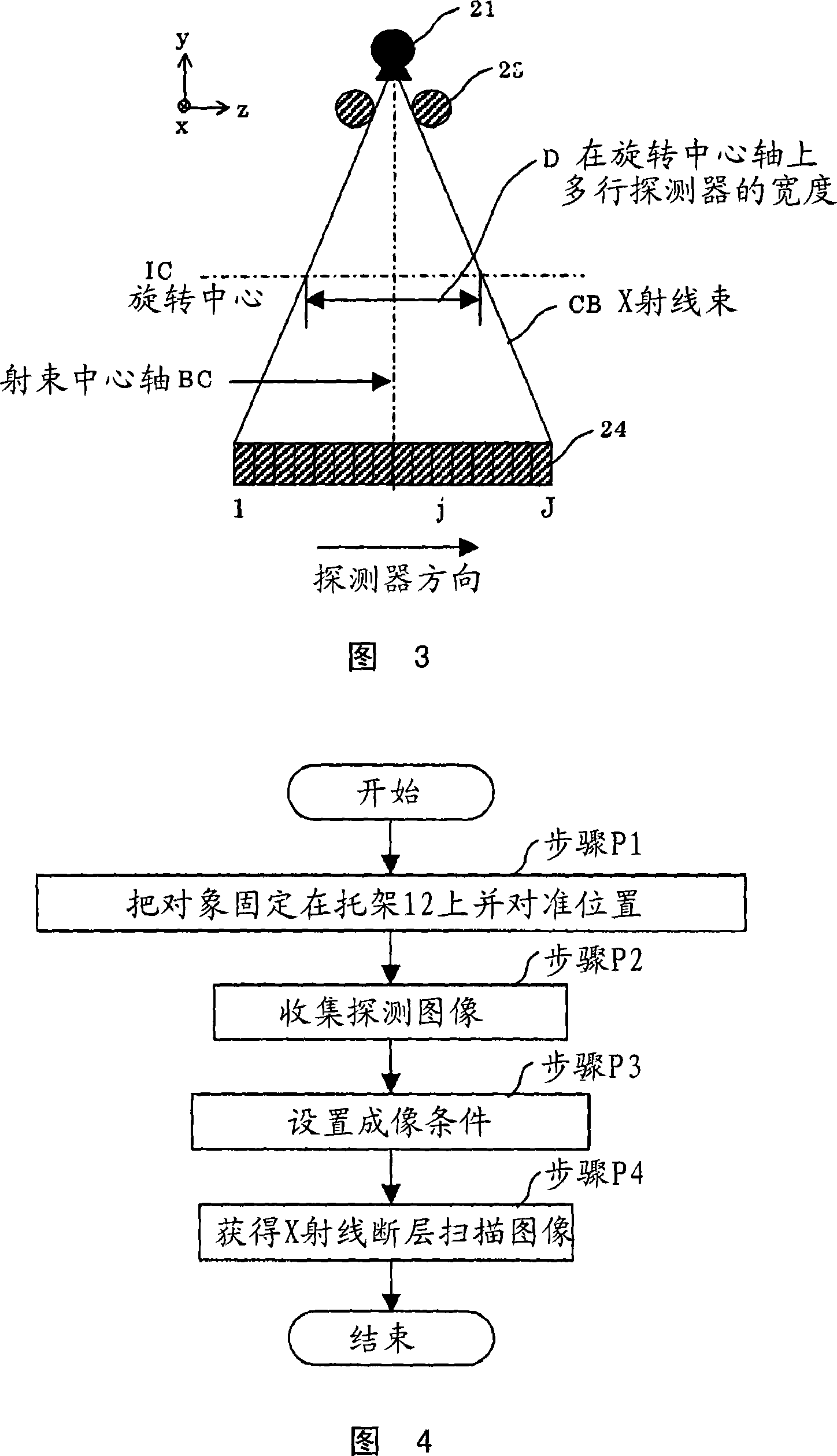

[0215] Furthermore, a case will be described with respect to Embodiment 3, in which the resolution in the channel direction is increased to improve the spatial resolution of the tomographic image by interleaving adjacent rows of X-ray detector data.

Embodiment 1

[0217] A case will be described with respect to Embodiment 1 in which data is collected by the multi-row X-ray detector 24 or the two-dimensional X-ray surface detector 24 using the X-ray detector module shown in FIG. 23 .

[0218] In this embodiment, since the data is collected by the multi-row X-ray detector 24 or the two-dimensional X-ray surface detector 24 using the X-ray detector module shown in FIG. X-ray detector data collected by X-ray detectors in X-ray detector.

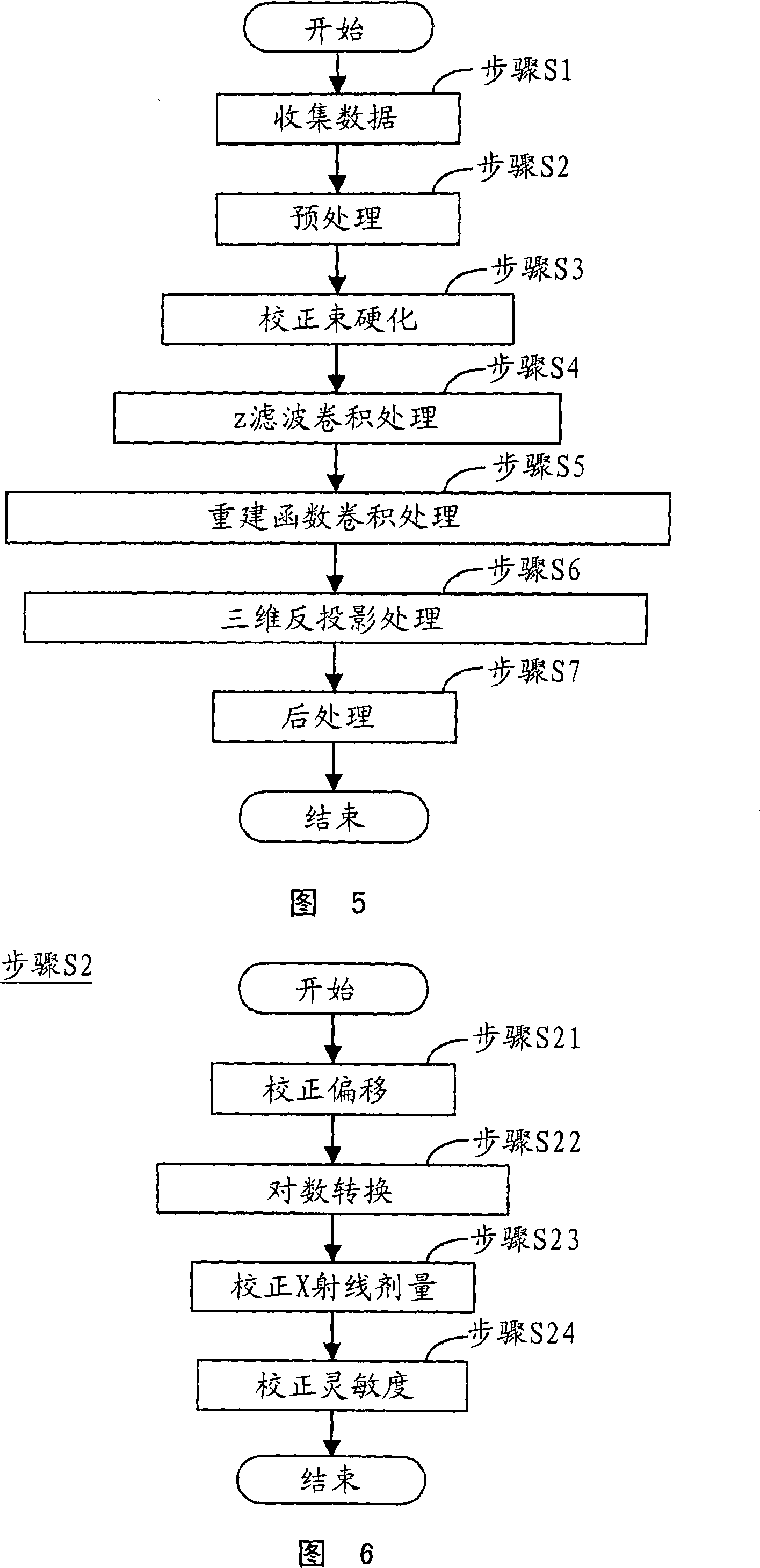

[0219] The preprocessing and reconstruction function convolution processing in this case includes the preprocessing of step S2 of FIG. 5 as described above, and the beam hardening correction of step S3, the Z filter convolution processing of step S4, the step Reconstruction function convolution processing in S5 and post-processing in step S7.

[0220] In addition, in the image reconstruction of the three-dimensional back-projection process in step S6, the three-dimensional back-projection process is perfo...

Embodiment 2

[0330] Embodiment 2 shown in FIG. 36 is a form of Embodiment 1 in which the peripheral portion of the X-ray detector module is made easier to manufacture.

[0331] In Example 2, a houndstooth structure substantially similar to that in Example 1 was used.

[0332] Also in Embodiment 2, the preprocessing, reconstruction function convolution, etc. are similar to the preprocessing of step S2, the beam hardening correction of step S3 and the z-filter convolution processing of step S4, the reconstruction function convolution of step S5 and the step S7 for post-processing.

[0333] In the three-dimensional back-projection processing of step S6, by similarly using the three-point weighted addition processing of Embodiment 1, data extraction can be completed without blurring the projection data, and image reconstruction can be achieved without deteriorating the obtained by three-dimensional back-projection processing Spatial resolution of X-ray tomography images.

[0334] The method ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com