Technology for making pigment pattern edge to form colour stone-imitation seam by pattern die

A pattern and color technology, applied in the field of artificial stone imitation pattern plate, to achieve the effect of extensive use value, low water absorption, good pattern characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0089] Below in conjunction with accompanying drawing and preferred embodiment, a kind of pattern mold that proposes according to the present invention makes the edge of color material pattern can form the specific implementation mode, structure, feature and effect of the process of the process of colored imitation stone line seam, detailed description as follows .

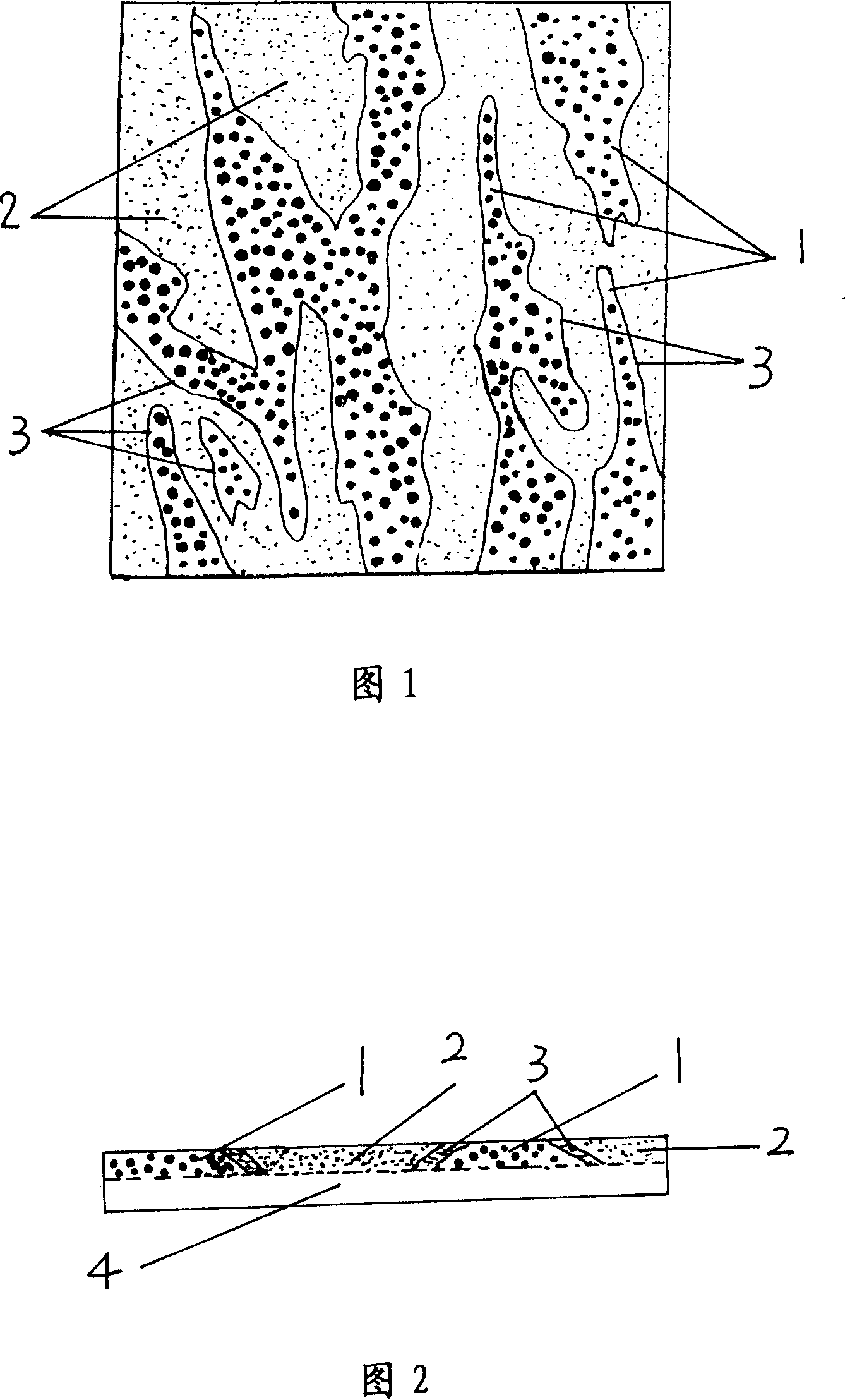

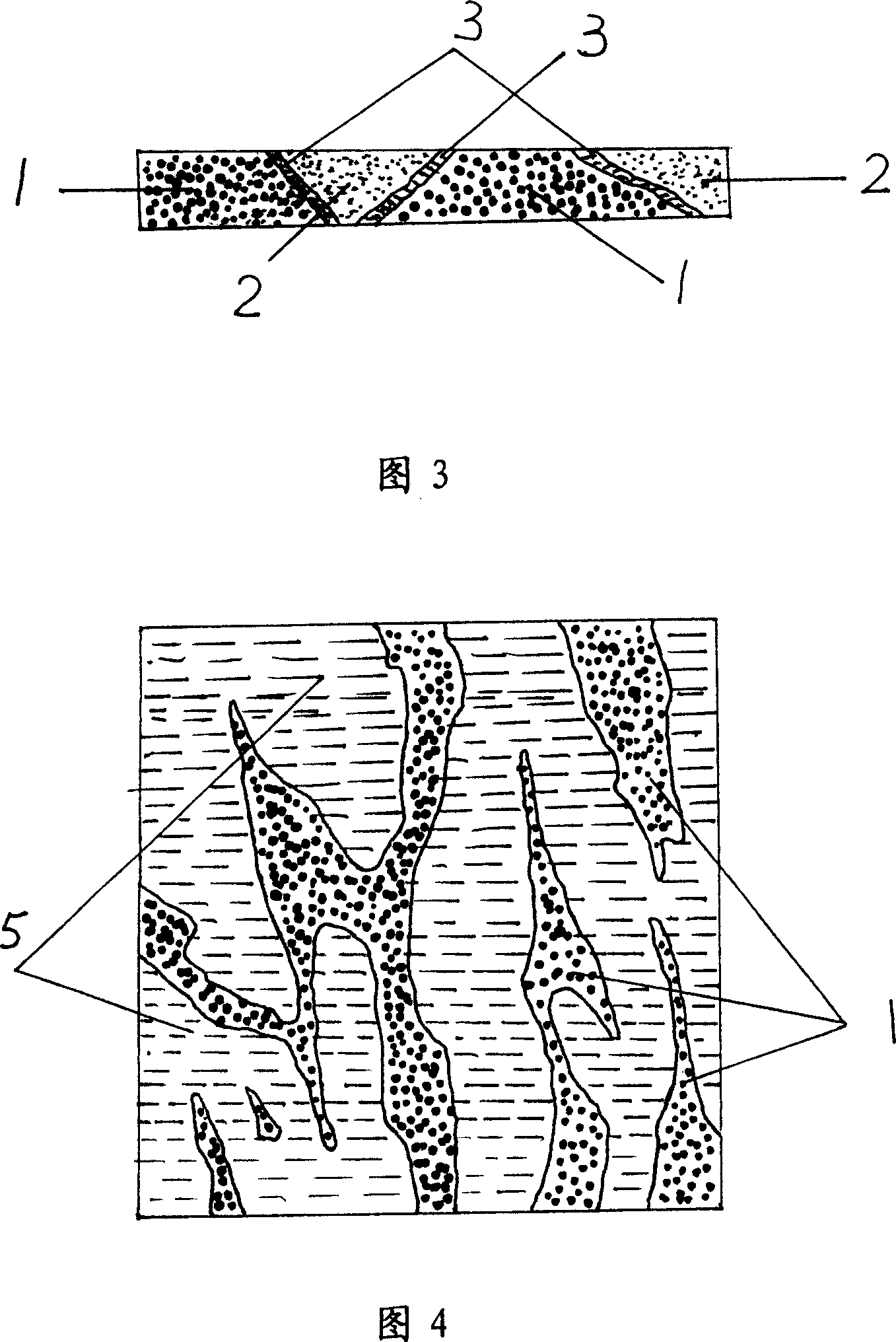

[0090] Please refer to FIG. 1 , which is a schematic plan view of a 600×600mm imitation gold-red line beige natural stone pattern plate product of the first embodiment of the process of making the edge of the color material pattern form a colored stone-like seam by a pattern mold of the present invention. The pattern area of the large black dot part (1) represents the yellow color area of the porcelain material, the pattern area of the small black dot part (2) represents the light yellow color area of the porcelain material, and the black line part (3) represents the porcelain material A translucent golden...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com