Looper for tufting machine

A technology of clamping device and tufting machine, which is applied in the field of carpet manufacturing, can solve problems such as the difficulty of finding a compromise solution, and achieve high-quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

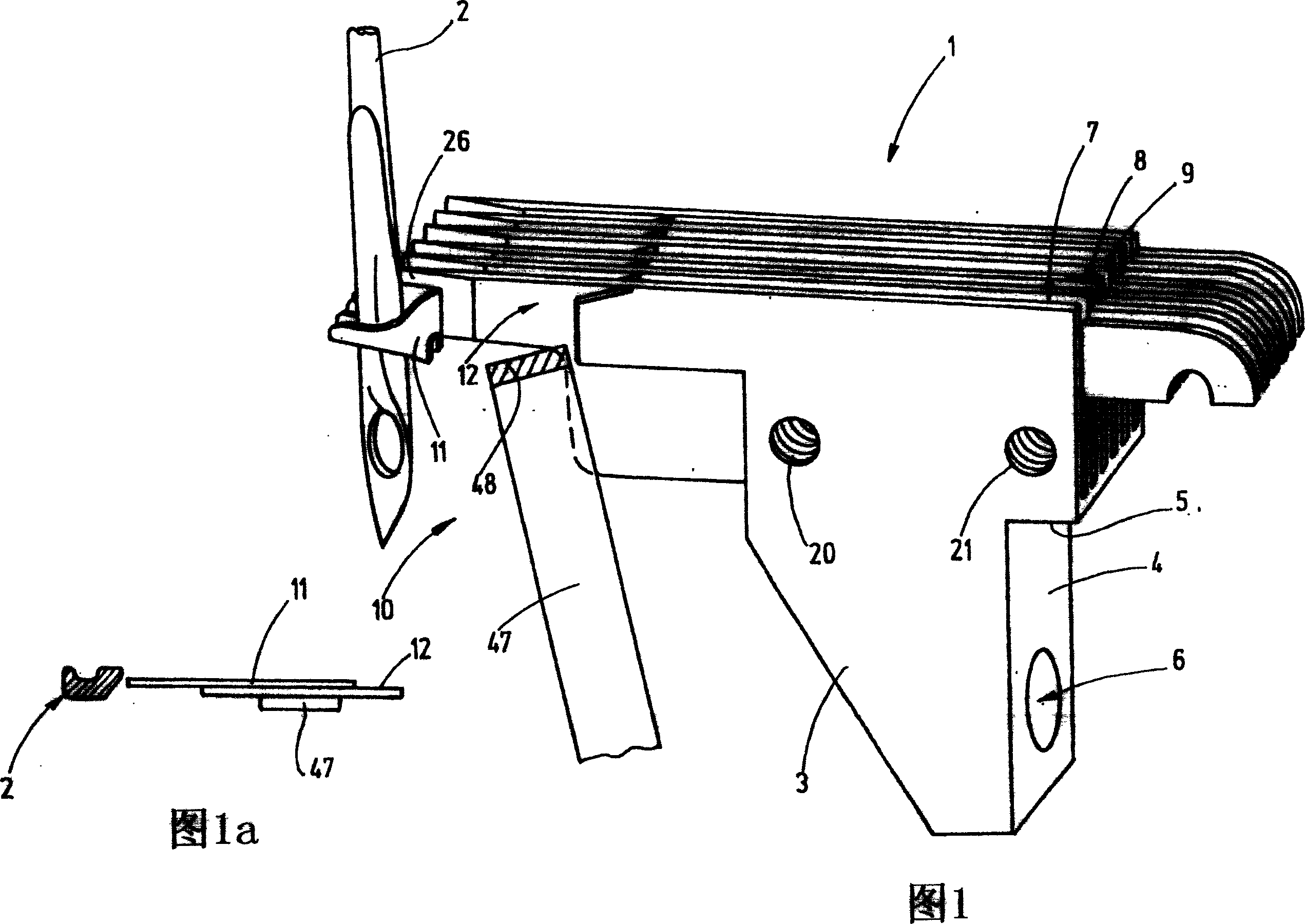

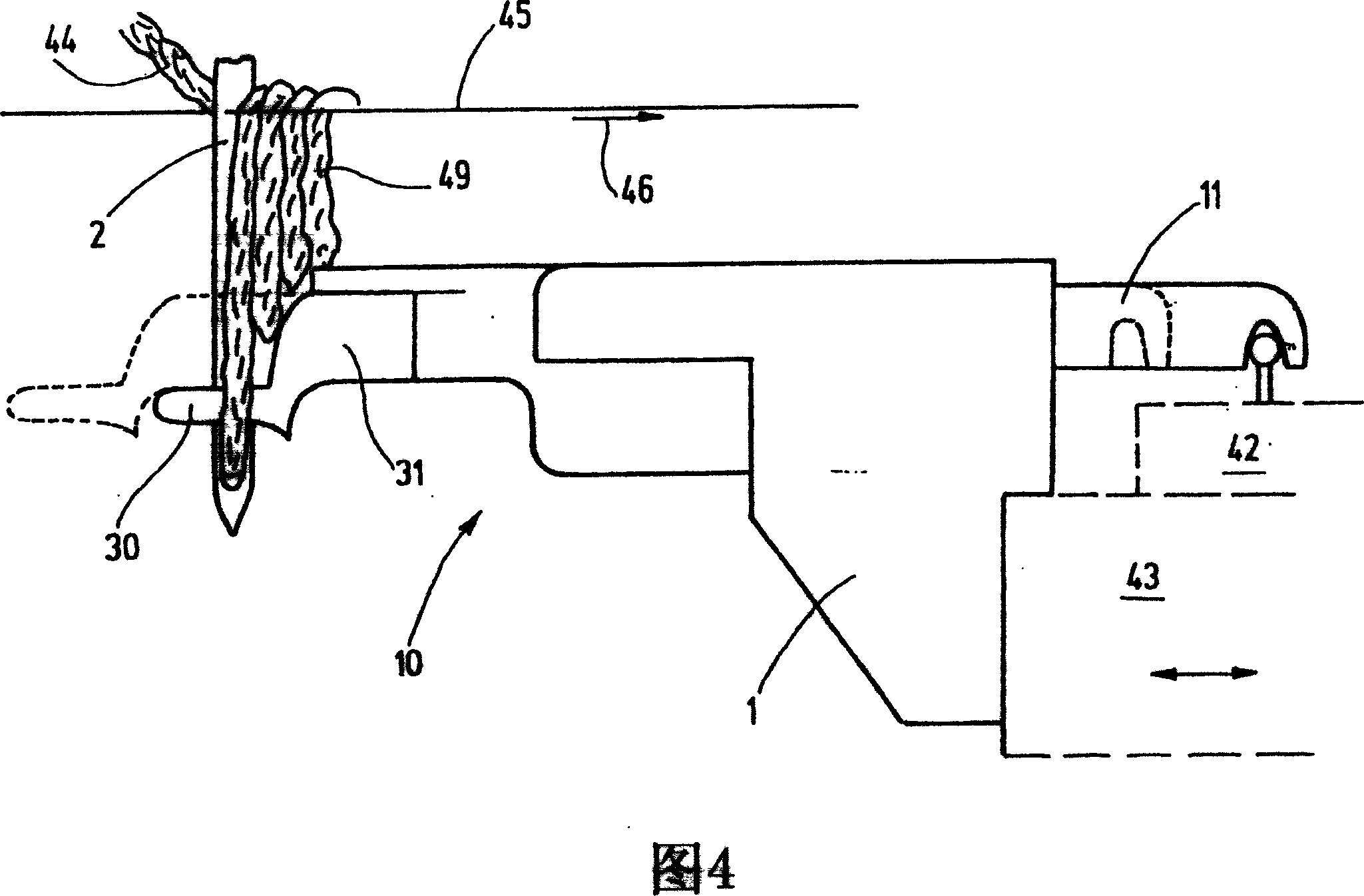

[0023] Figure 1 shows a module 1 in relation to a tufting machine, in which many such modules are used. These modules are mounted adjacent to each other to a bar extending in a transverse direction with respect to the direction of movement of the carpet to be manufactured, and preferably underneath said carpet. Furthermore, the tufting machine comprises a bar with tufting needles, one of these tufting needles 2 being shown in FIG. 1 . These needles are used to thread the pile yarn through the base fabric. This module is arranged to support the pile loops thus produced and to release them harmlessly, or to cut said pile loops as required.

[0024] The module 1 comprises a base body 3 having support surfaces 4, 5 for said bars. The holes 6 are used to mount the module 1 to the bar.

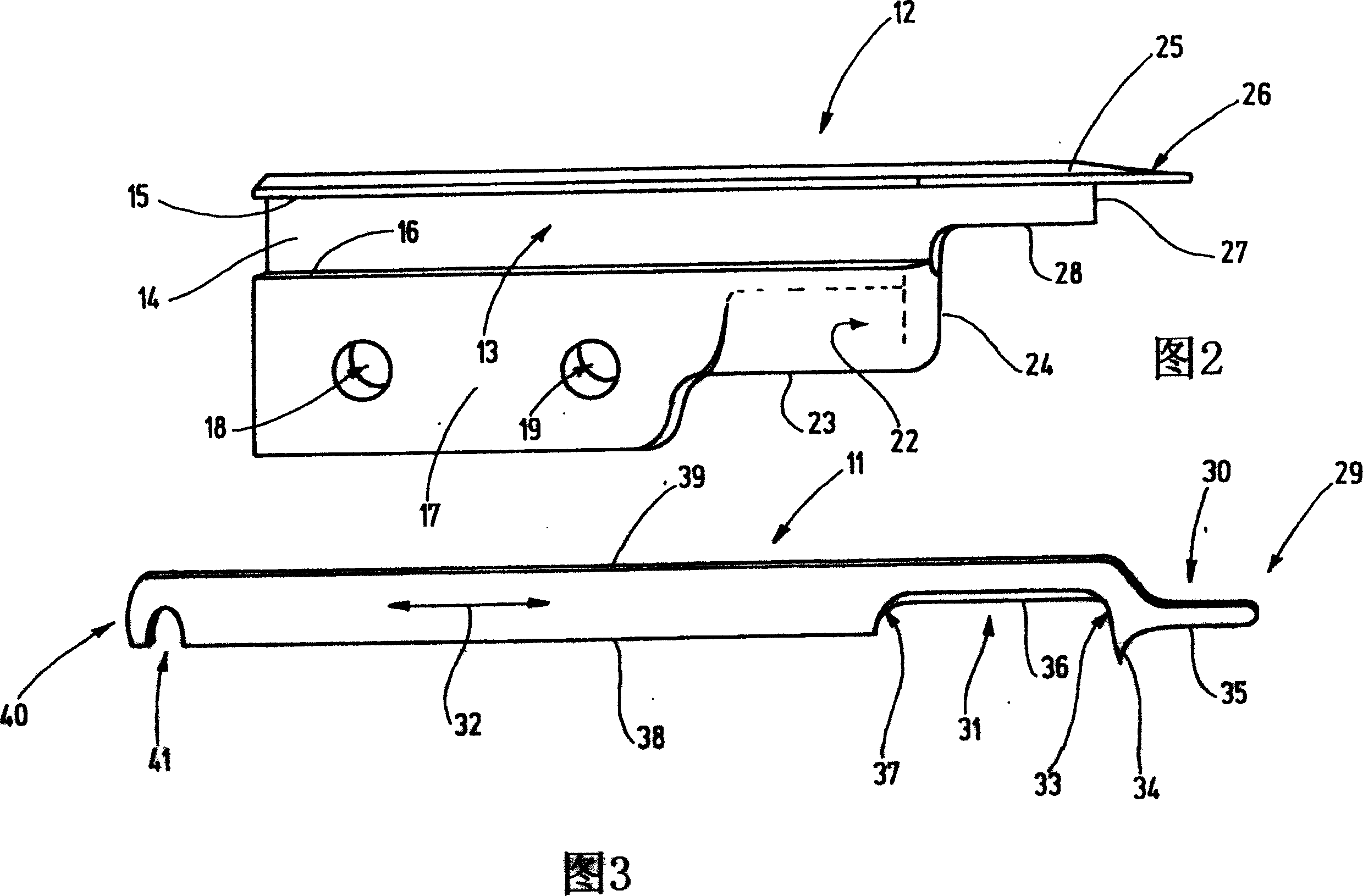

[0025] The modules are arranged on their side facing the base fabric (figure 1, top) with grooves 7, 8, 9 aligned parallel to one another and in this case respectively seated against said grooves...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com