Method for realizing high-water containing same-well injection-production by multi-cup equi-flow type down-hole oil-water separator

An oil-water separator, injection-production technology in the same well, which is applied in wellbore/well components, production fluids, earth-moving drilling and production, etc., can solve the problems of poor separation effect and cannot be applied on a large scale, and achieves the goal of reducing water injection costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

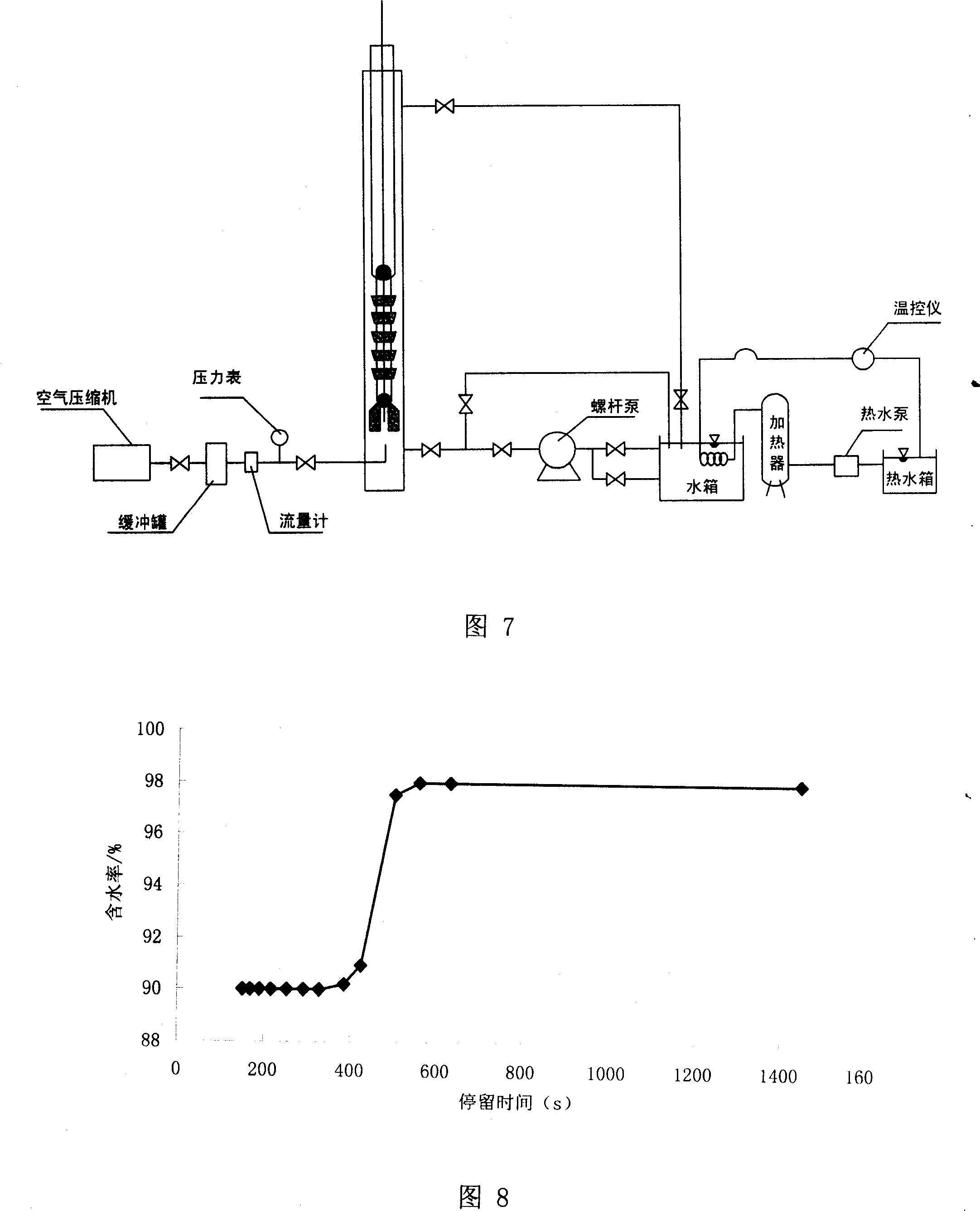

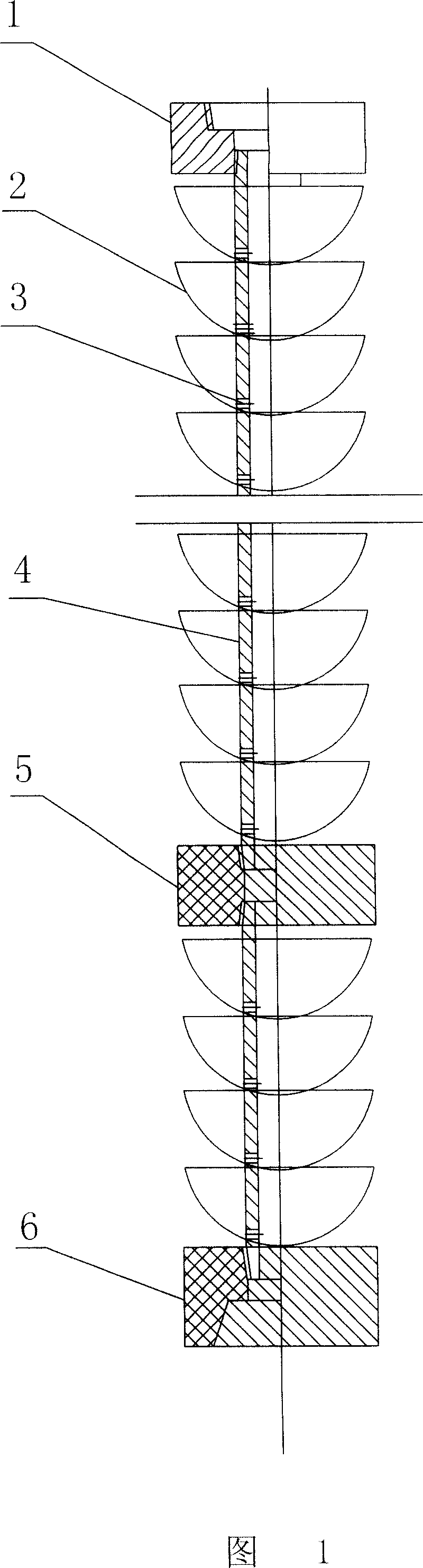

[0019] The present invention will be further described below in conjunction with accompanying drawing:

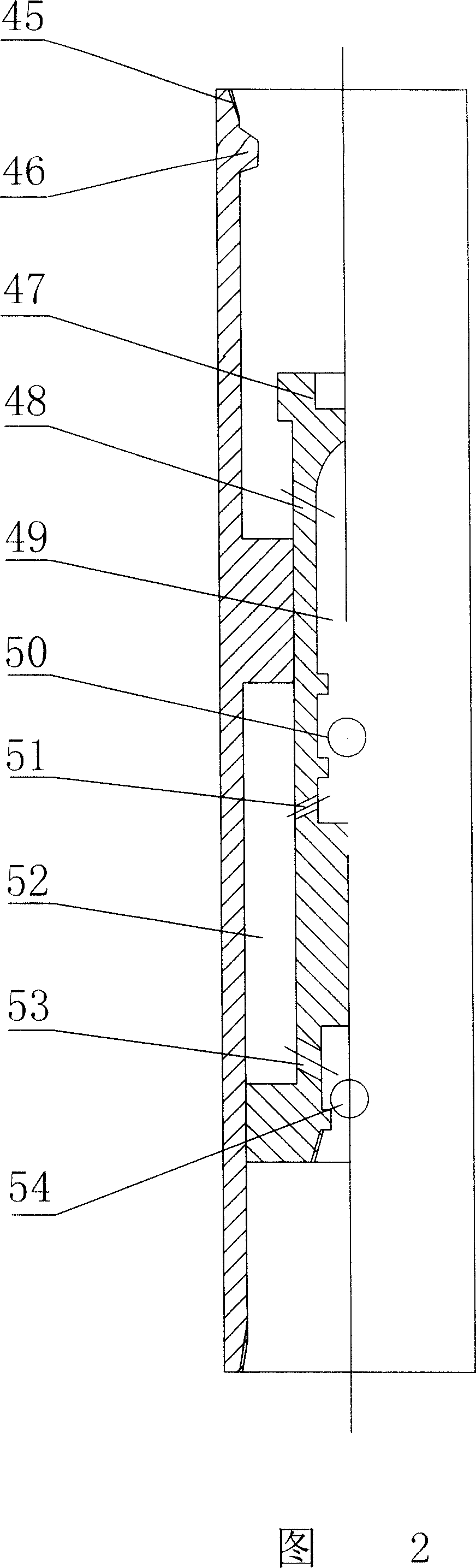

[0020] Firstly, the basic idea of the present invention is introduced, which is to use a multi-cup iso-flow downhole oil-water separator to make the production liquid of the production layer flow downhole through the settling cup in the separator to naturally settle according to the law of light oil and water weight. , After the water is fully separated, the production fluid with low water content is lifted to the ground by the production pump through the liquid flow channel of the production pump, and the production fluid with high water content is injected back to the injection pump through the liquid flow channel of the injection pump. Therefore, one of the keys to realize the present invention is to fully separate the oil and water, and the second key is to build two independent liquid flow channels and a lifting device compatible with the two liquid flow channels.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com