Bauxite in-situ leaching mining method

A mining method and bauxite technology, applied in mining fluids, earth cube drilling, boreholes/well components, etc., can solve problems such as high safety risks, high manpower and material costs, long construction period, etc., and achieve efficient mining and protection Mine environment, the effect of solving environmental damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

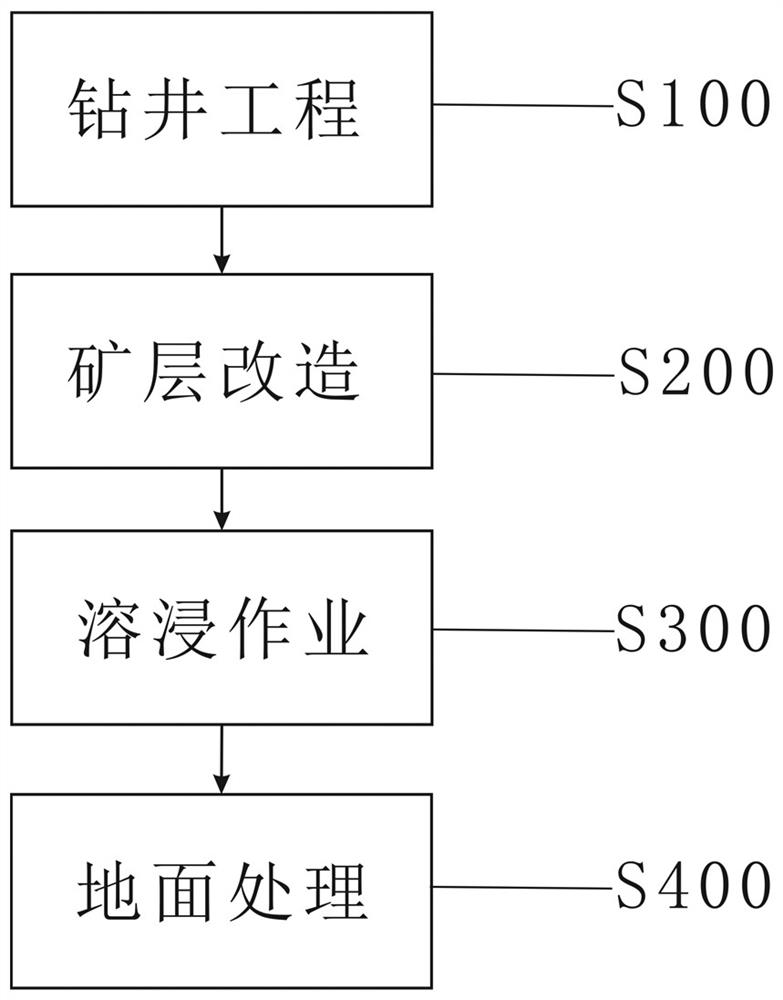

[0047] A method for in-situ leaching mining of bauxite, comprising the steps of:

[0048] (1) Drilling engineering:

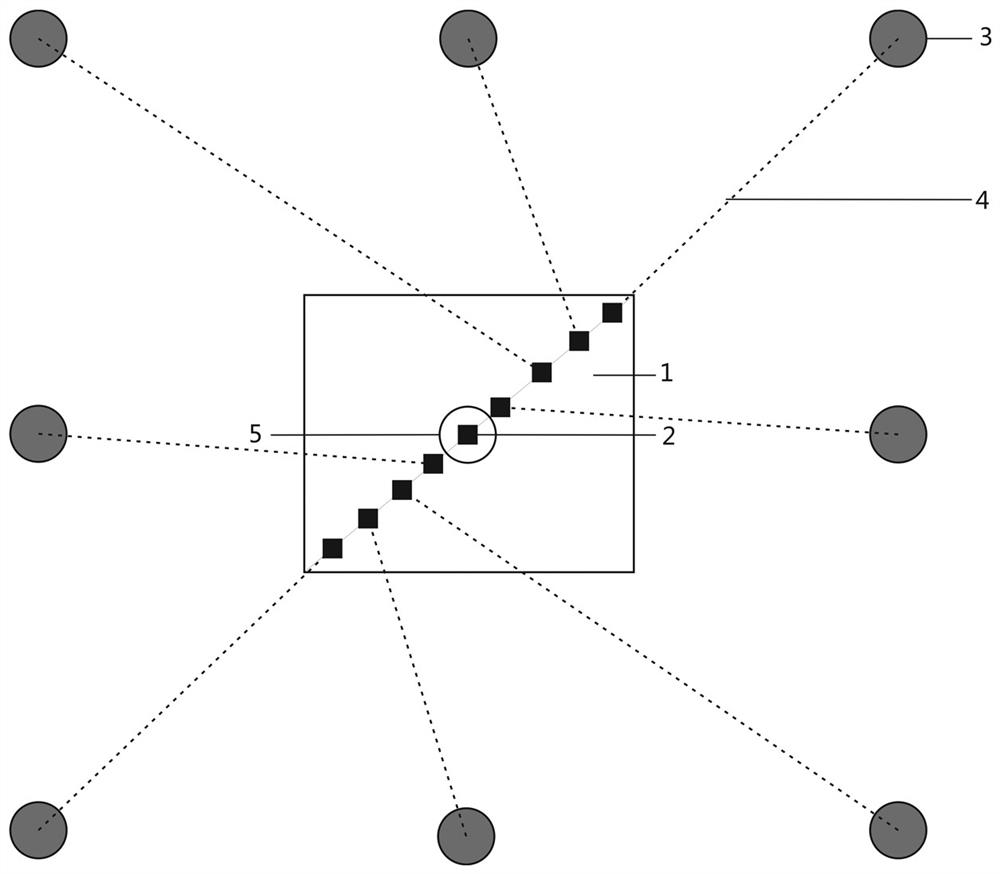

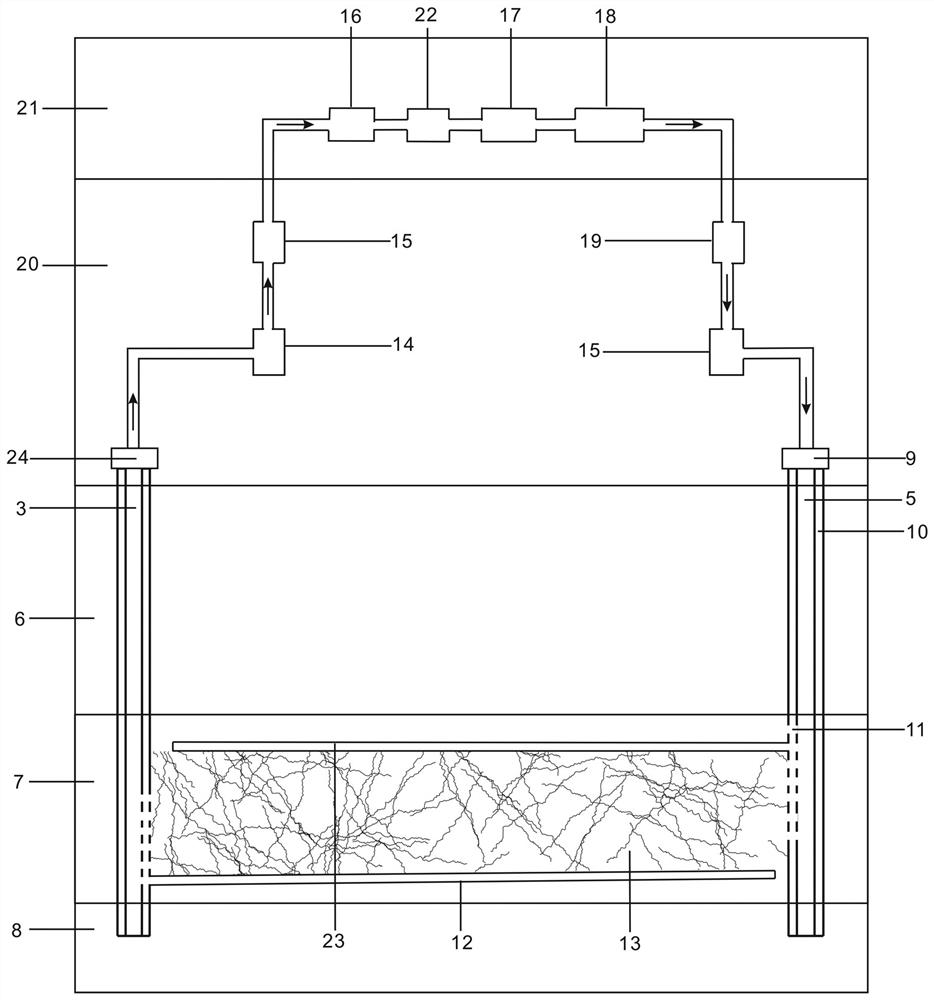

[0049]Use secondary wells; the surface well site 1 adopts "inline" well layout, and the drilling rig slides from the first notch to the last notch one by one. In order to meet the anti-collision requirements, the minimum wellhead spacing is set to 5m; method, reverse seven-point method or reverse five-point method, and the well spacing is 50-100m; including 1 liquid injection well 5 and 8 drainage and production wells 3, the liquid injection well 5 is located in the middle position, and the drainage and production well 3 Located in the peripheral position; Among them, the liquid injection well 5 is a vertical well, and the drainage well 3 is a directional well. The directional well trajectory 4 should pay attention to anti-collision and circumvention. The maximum inclination angle does not exceed 35°. , the well inclination angle is less than 10°, which reduce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com