A method for in-situ mining of oil shale

A technology of in-situ mining and oil shale, which is applied in the direction of mining fluid, earthwork drilling, wellbore/well components, etc. It can solve the problems of long electric heating time, kerogen needs to be improved, and low safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0037] According to one embodiment, the proppant containing magnetic nano-catalyst is prepared by the following method:

[0038] a. Contact the mixed solution of ferric salt and ferrous salt with alkaline aqueous solution to form Fe through hydrolysis and crystallization 3 o 4 particle;

[0039] b. Fe 3 o 4 Particles as carriers, in the Fe 3 o 4 supporting the transition metal on the particles to prepare supported catalyst particles;

[0040] c. ultrasonically stirring the supported catalyst particles in water for 0.5-2 hours, so that the particles are evenly dispersed in water to obtain the first dispersion system;

[0041] d. Mix the first dispersion system with the proppant, and ultrasonically stir for 0.5-2 hours to obtain the second dispersion system;

[0042] e. Centrifuge the second dispersion system, and heat the solid obtained after centrifugation at 150-200° C. for 5-10 hours to obtain the proppant containing the magnetic nano-catalyst.

[0043]In step a, the...

Embodiment

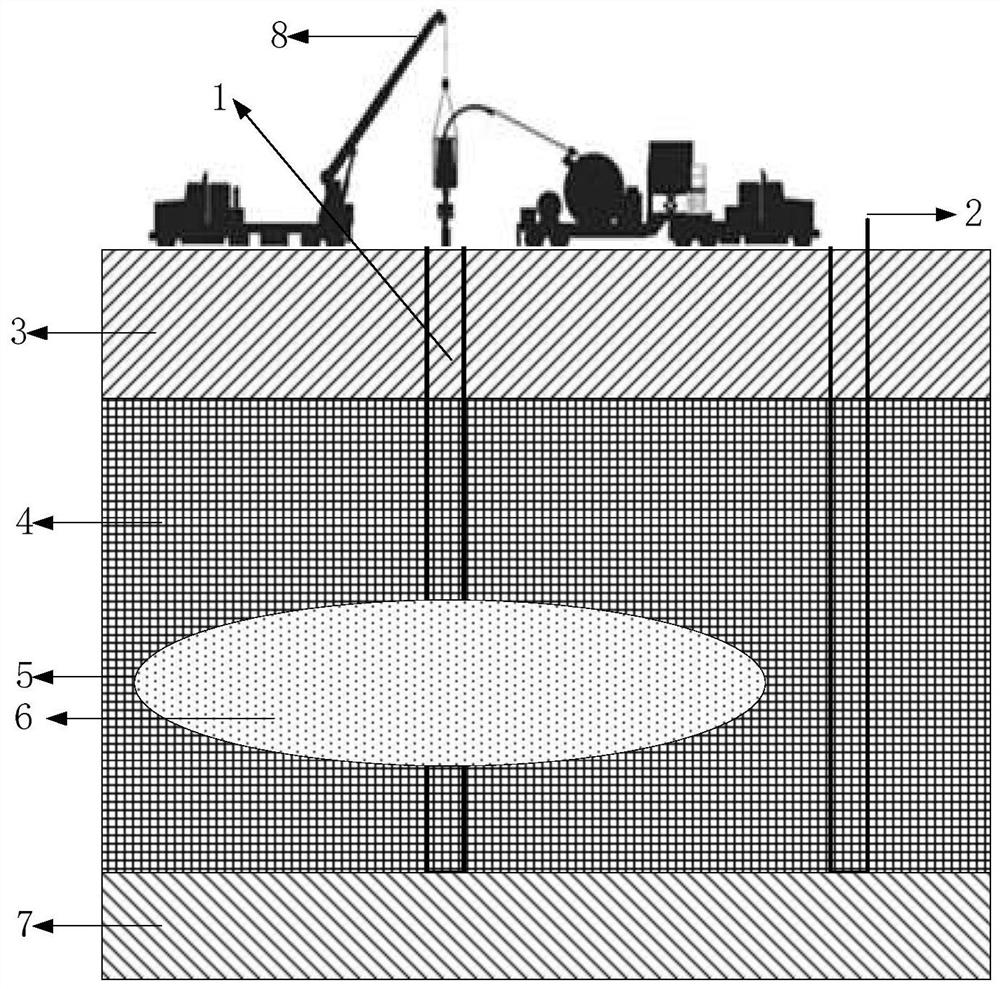

[0054] The method for in-situ mining of oil shale in this embodiment is as follows: figure 1 shown.

[0055] The oil shale in a certain place is deeply buried, generally 300-500m, and must be exploited underground. The average thickness of the oil shale reservoir 4 is about 26m, the average oil content is as high as 13%, and the total water content is 4%. The method specifically includes:

[0056] (1) Drill two vertical wells from the surface of the oil shale distribution area to penetrate the oil shale reservoir 4: one is a heating well 1 and the other is a production well 2, and the spacing between the wells is about 50m, and they are completed with casing;

[0057] (2) Preparation of magnetic nanoparticles by hydrolysis: ferric salt (Fe 3+ ) and ferrous salt (Fe 2+ ) is directly added to ammonia water, and the iron salt is instantly hydrolyzed and crystallized to form Fe 3 o 4 Nanoparticles (average particle size is 250nm);

[0058] (3) with the Fe 3 o 4 Nanoparticl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com