Photoelectric conversion solar vacuum glass composite straight-through transducing tube

A technology of solar vacuum glass and heat conversion, applied in the field of solar energy applications, can solve problems such as unsatisfactory pressure-bearing operation, and achieve the effect of easy processing and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

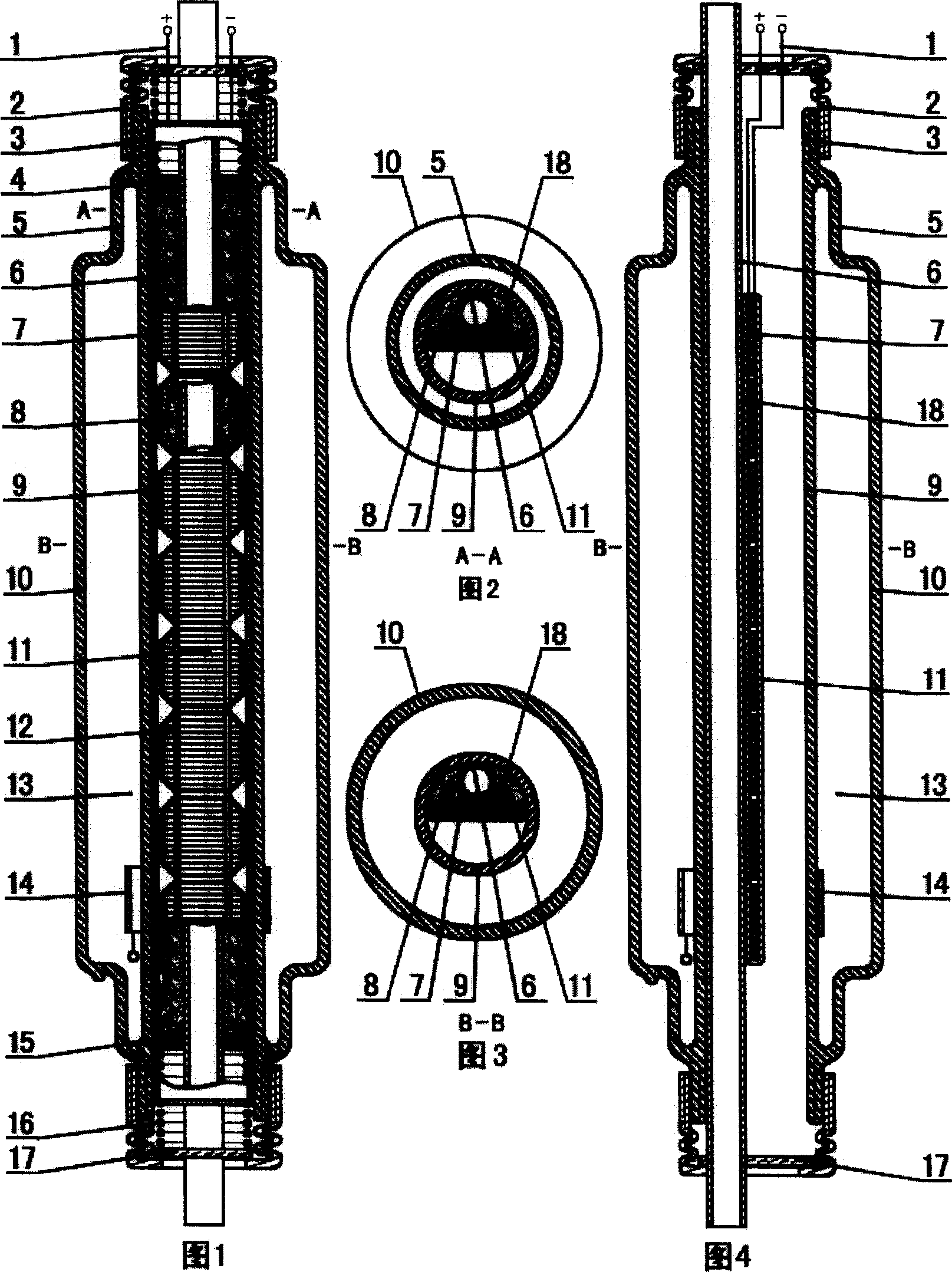

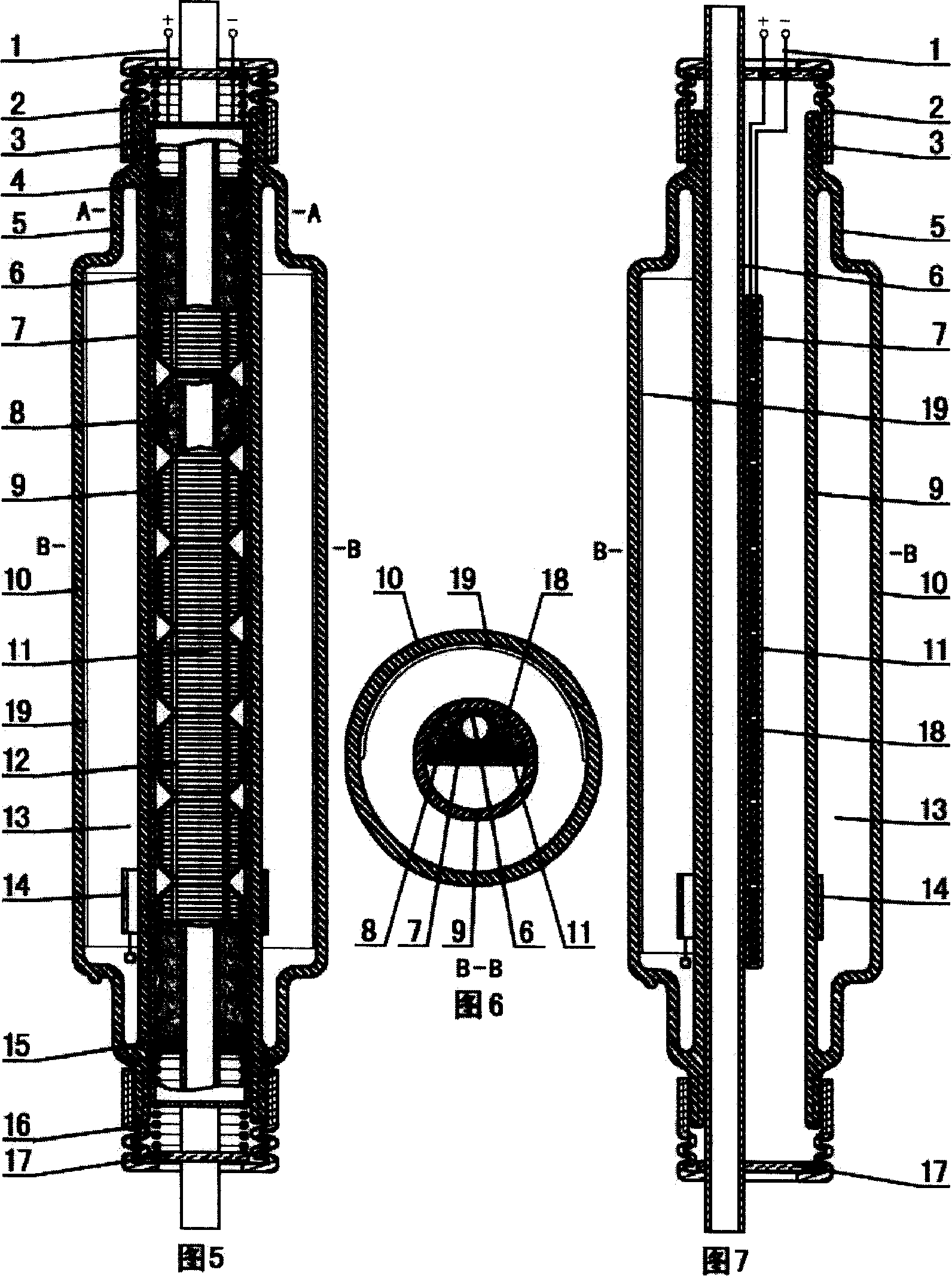

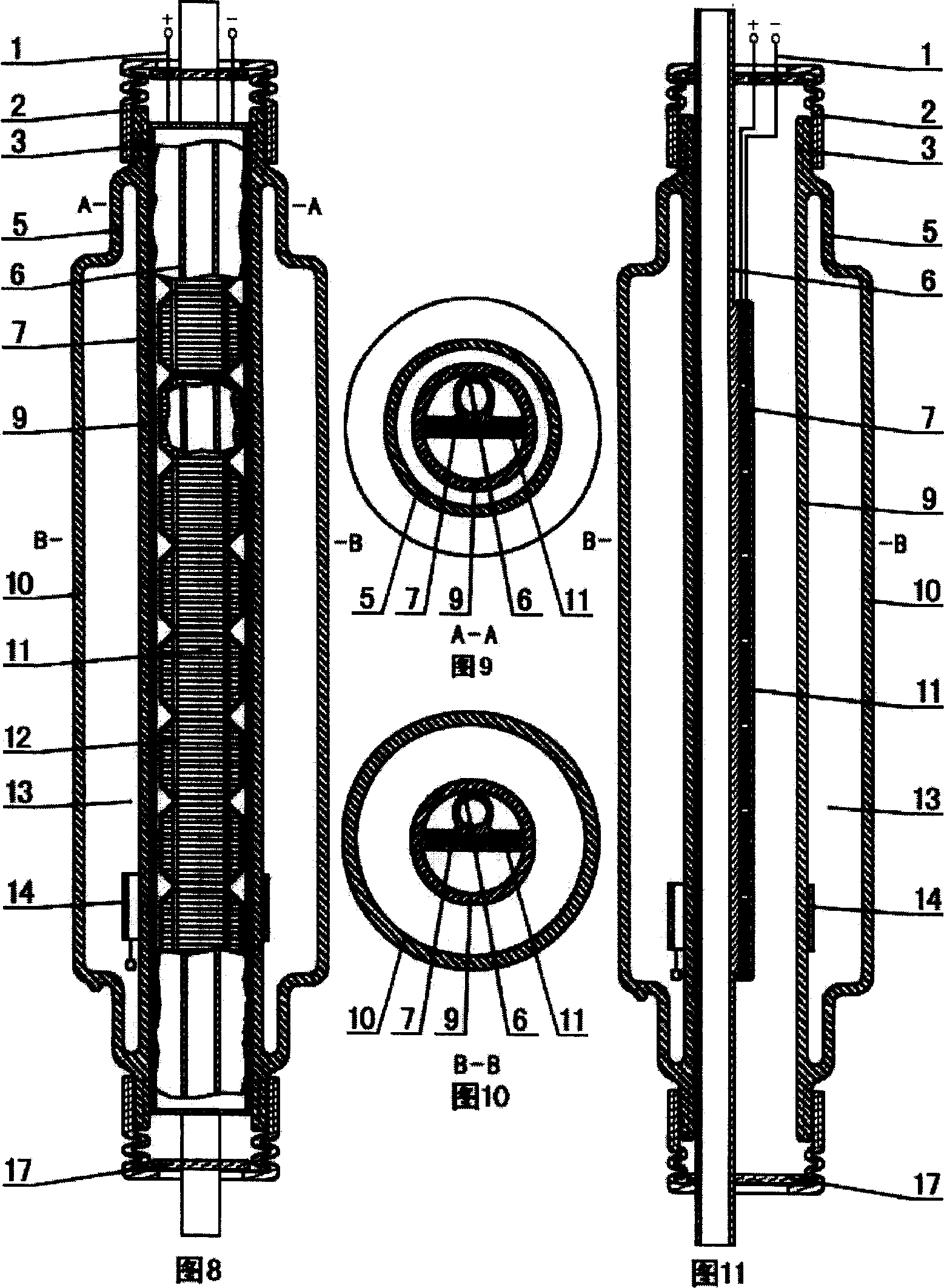

[0092] In the first embodiment: the photoelectric-thermal conversion solar vacuum glass composite straight-through inverter is composed of a light-transmitting outer glass tube 10, a photovoltaic cell 11, a battery connecting wire 12, an inner glass tube 9, a getter 14, a fluid tube 6, and a heat-conducting material 8. The energy tube, the light-transmitting glass plate 7 annularly seals the photovoltaic cell 11 by evacuating glass and welding, the positive and negative electrodes of the photovoltaic cell group are sealed and exported through the wire 1, and the outside of the fluid pipe 6 on the heat conduction plate side 18 of the photovoltaic cell 11 is filled with heat conduction material 8. Photovoltaic cells 11 are positioned and mounted on the diameter of the light-transmitting outer glass tube 10 . The inner glass tube 9 and the outer glass tube 10 equipped with an exhaust nozzle are eccentrically and variable-diameter set together in parallel, supported and positioned...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com