Three-phase heating system with abnormal detecting function and its detecting method

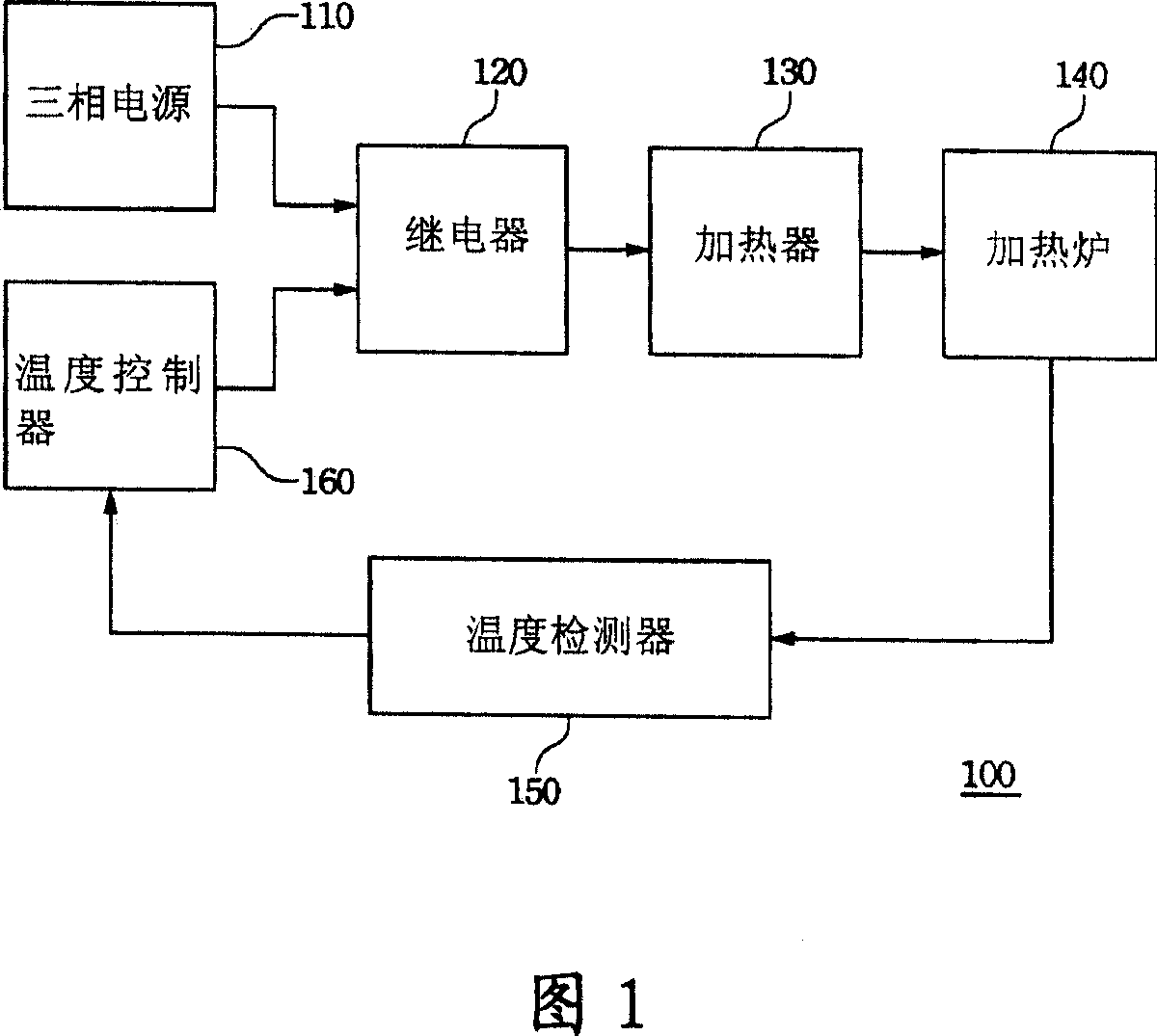

A heating system and abnormality detection technology, applied in electric heating devices, automatic disconnection emergency protection devices, electrical components, etc., can solve problems such as increased production cost, non-conformity, and influence of heating and manufacturing process conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

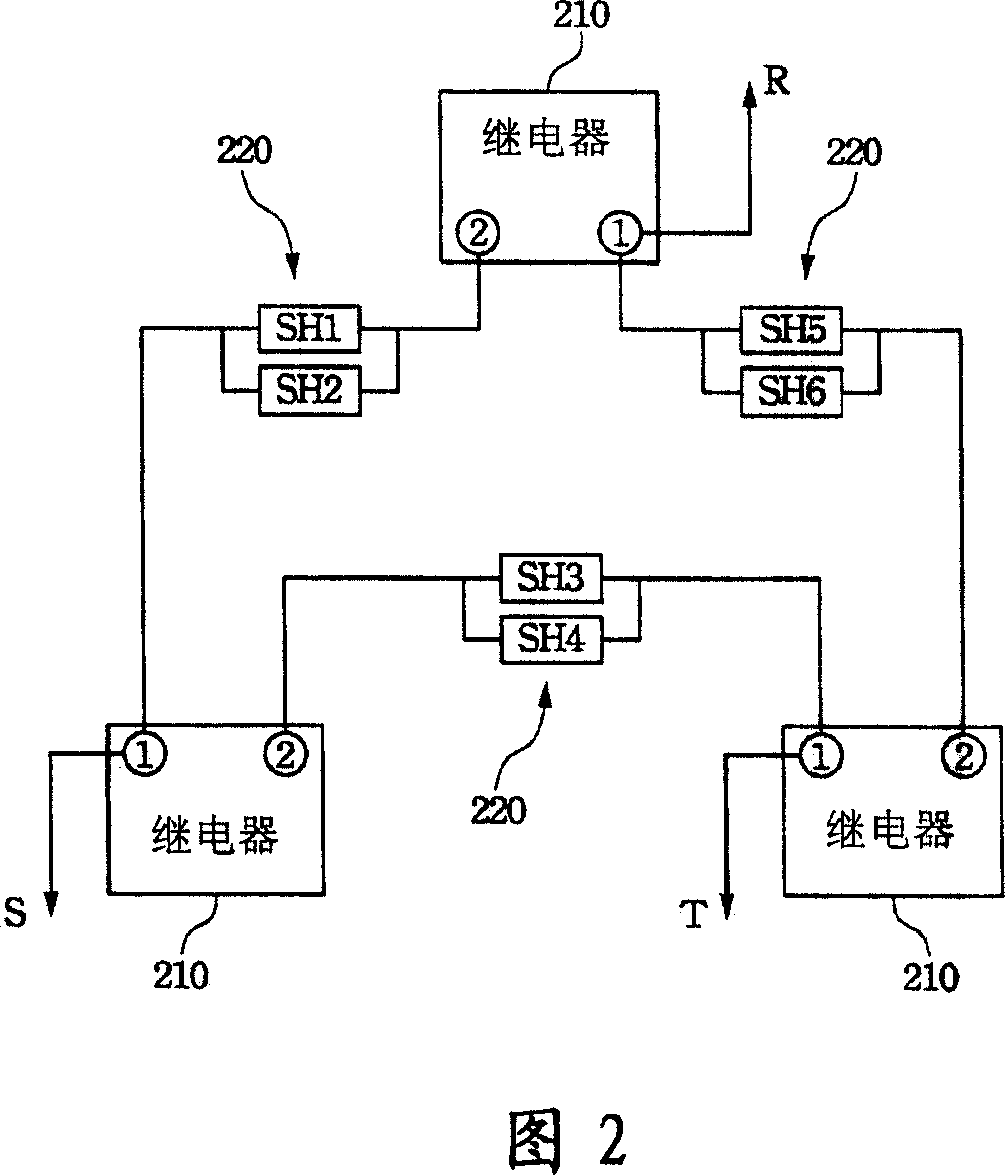

Method used

Image

Examples

Embodiment Construction

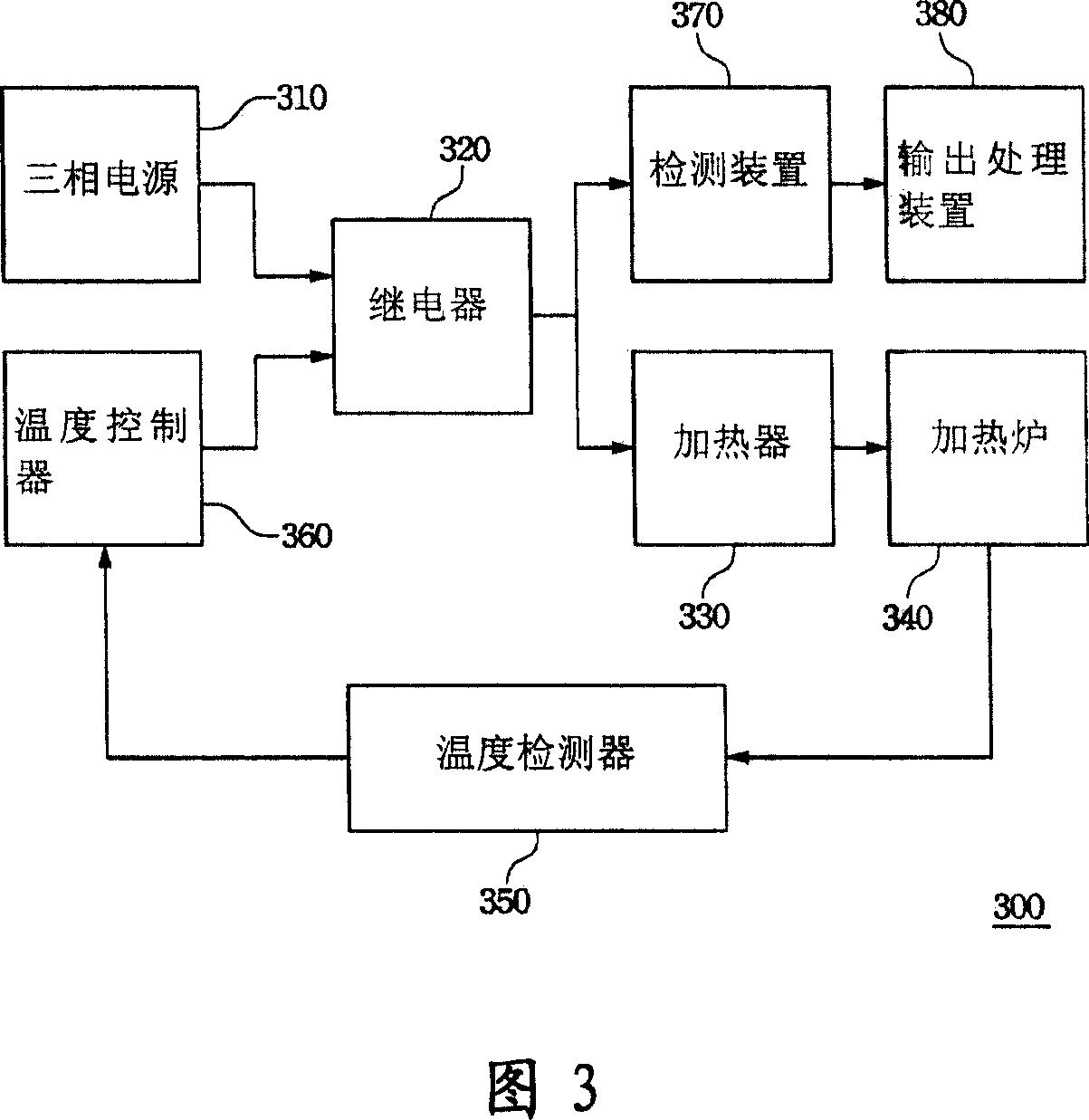

[0025] Please refer to FIG. 3 , which is a schematic block diagram of a three-phase heating system with an abnormality detection function according to an embodiment of the present invention. In the three-phase heating system 300 , the three-phase power supply 310 is used to input a voltage source to the relay 320 for the relay 320 to operate. The relay 320 is used to control the heater 330 to be turned on or off, and to heat the furnace 340 through the heater 330 . The heating furnace 340 is detected by the temperature detector 350, and then the detected temperature signal is transmitted to the temperature controller 360 through the temperature detector 350, and the temperature controller 360 controls the relay 320, so that the relay 320 controls the heater 330 The opening or closing of , and then maintain the temperature condition in the heating furnace 340. In addition, the three-phase heating system 300 also has a detection circuit for detecting whether the relay 320 is fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com