Hydraulic-driven cleaner and method for changing hydraulic-jet dynamics and direction

A cleaning machine and cleaning technology, applied in the field of cleaning machines, can solve the problems of increasing the development and production costs of cleaning machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

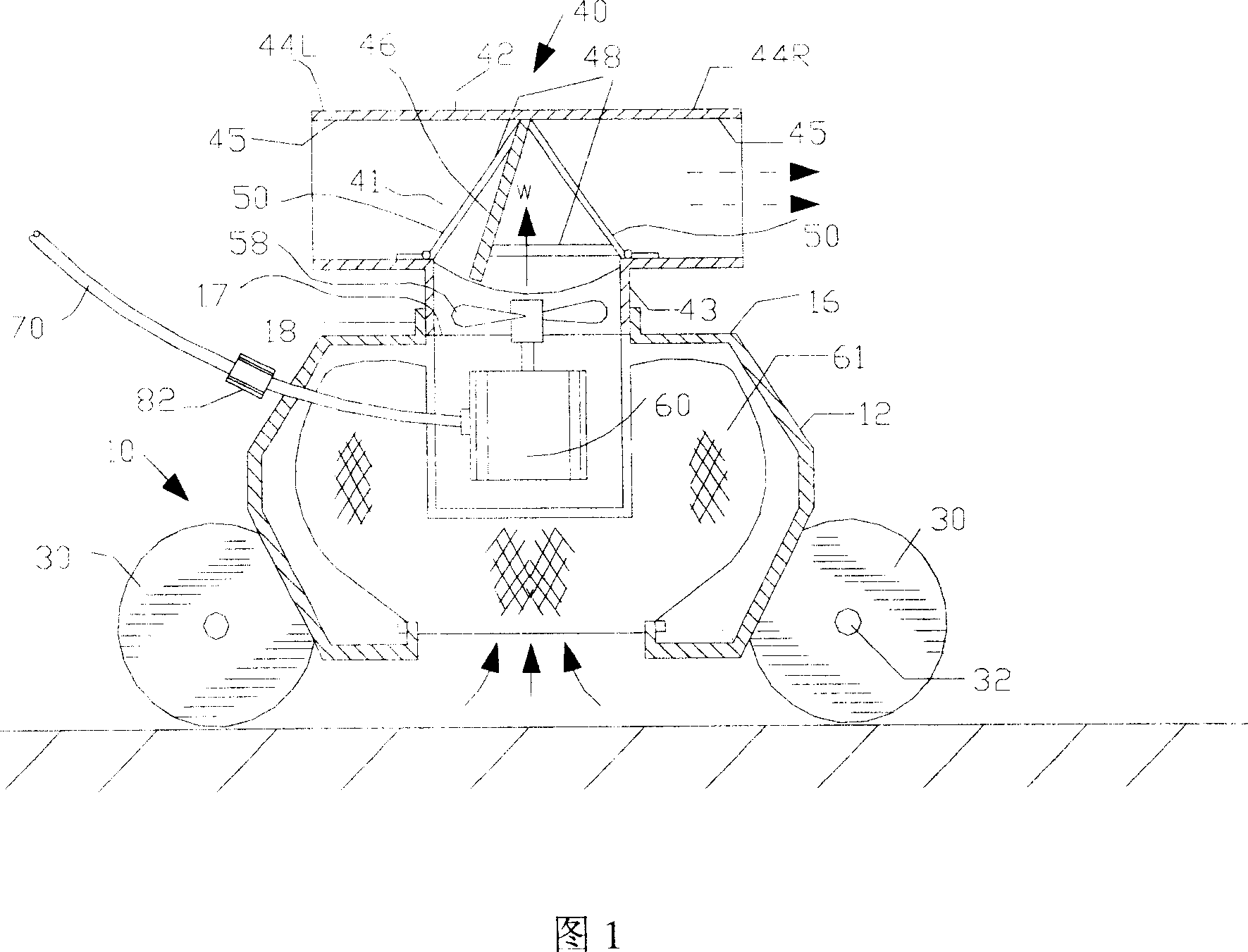

[0071] In the following description, the cleaning machine 10 includes a shell or cover frame 12 and a top cover wall 16, a built-in water pump and a drive motor 60, the water pump sucks pool water and debris in the water enters the cleaning machine through the gap 61 at the bottom of the cleaning machine, and this The notch is surrounded by filter means.

[0072] In the embodiment shown in Figures 1-11, a single motor is used as the pumping and driving means. The drive unit has simple mechanical directional control. In this embodiment, a brief interruption of the electrical current causes the cleaning machine to change direction. Current interruption can be activated using a smart current control switch or a mechanical contact.

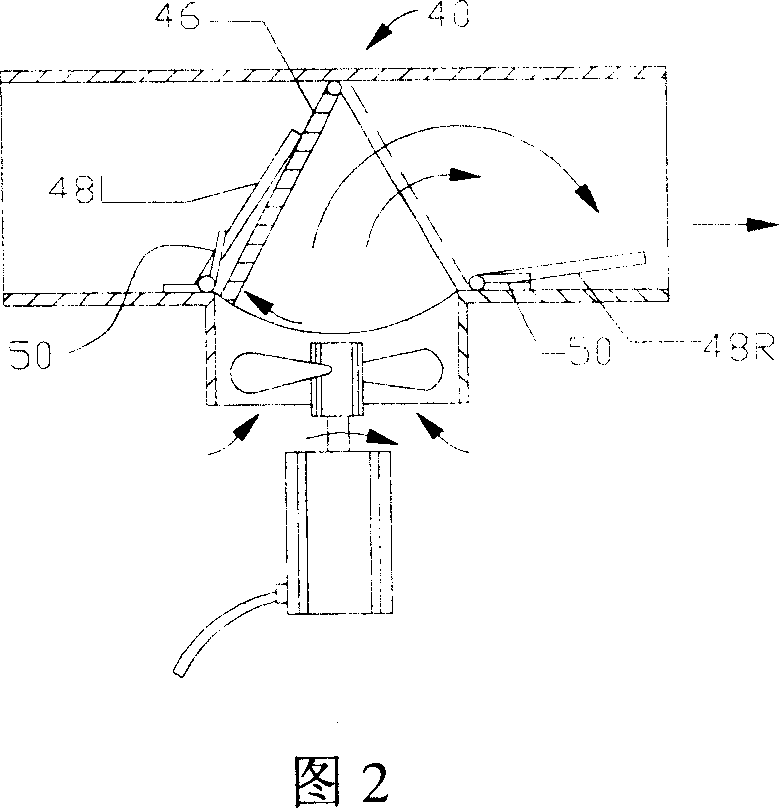

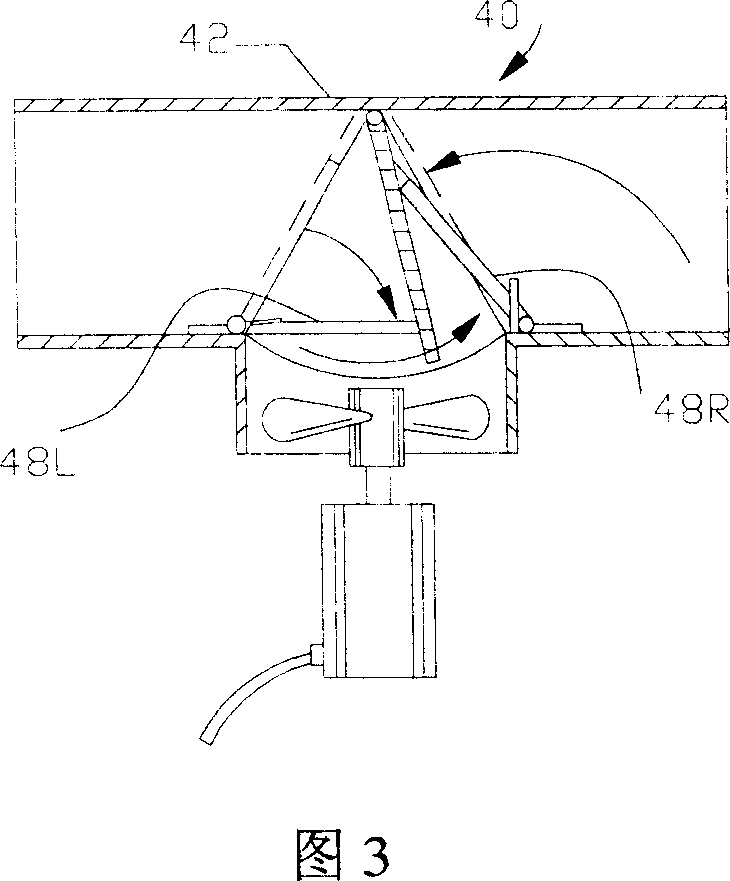

[0073] Figure 1 shows, in partial cross-section, a cleaning machine 10, including a water spray valve assembly 40, mounted on a motor-driven water pump 60, using blades 58 to propel a flow of water 'W' through the bottom of the housing from the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com