Device and method for controlling glass-board thickness evenness

A technology with uniform thickness and glass plate, which is applied in glass forming, glass forming, glass manufacturing equipment, etc. It can solve the problem of uneven plate thickness and achieve good thermal shock resistance, increased precision, and high thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

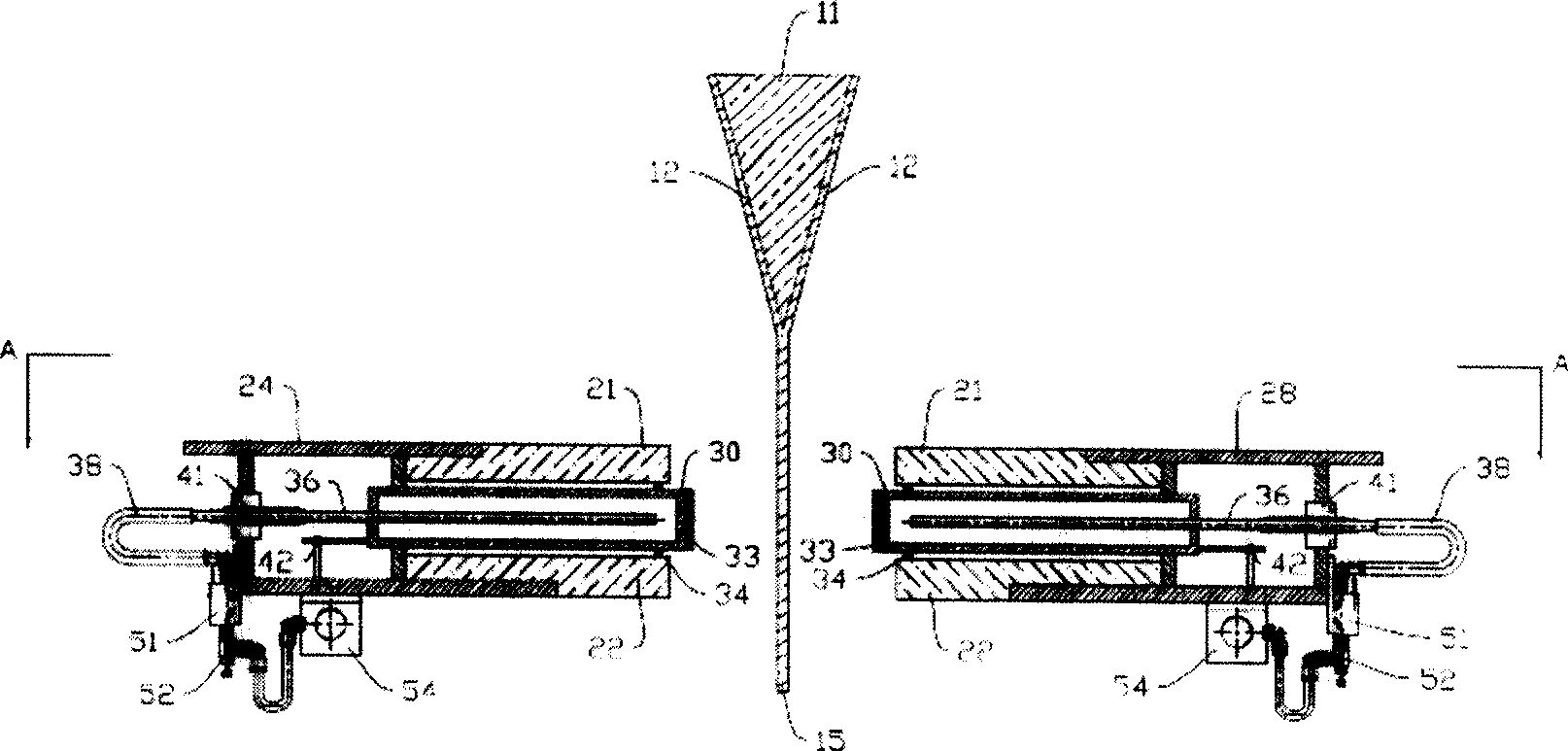

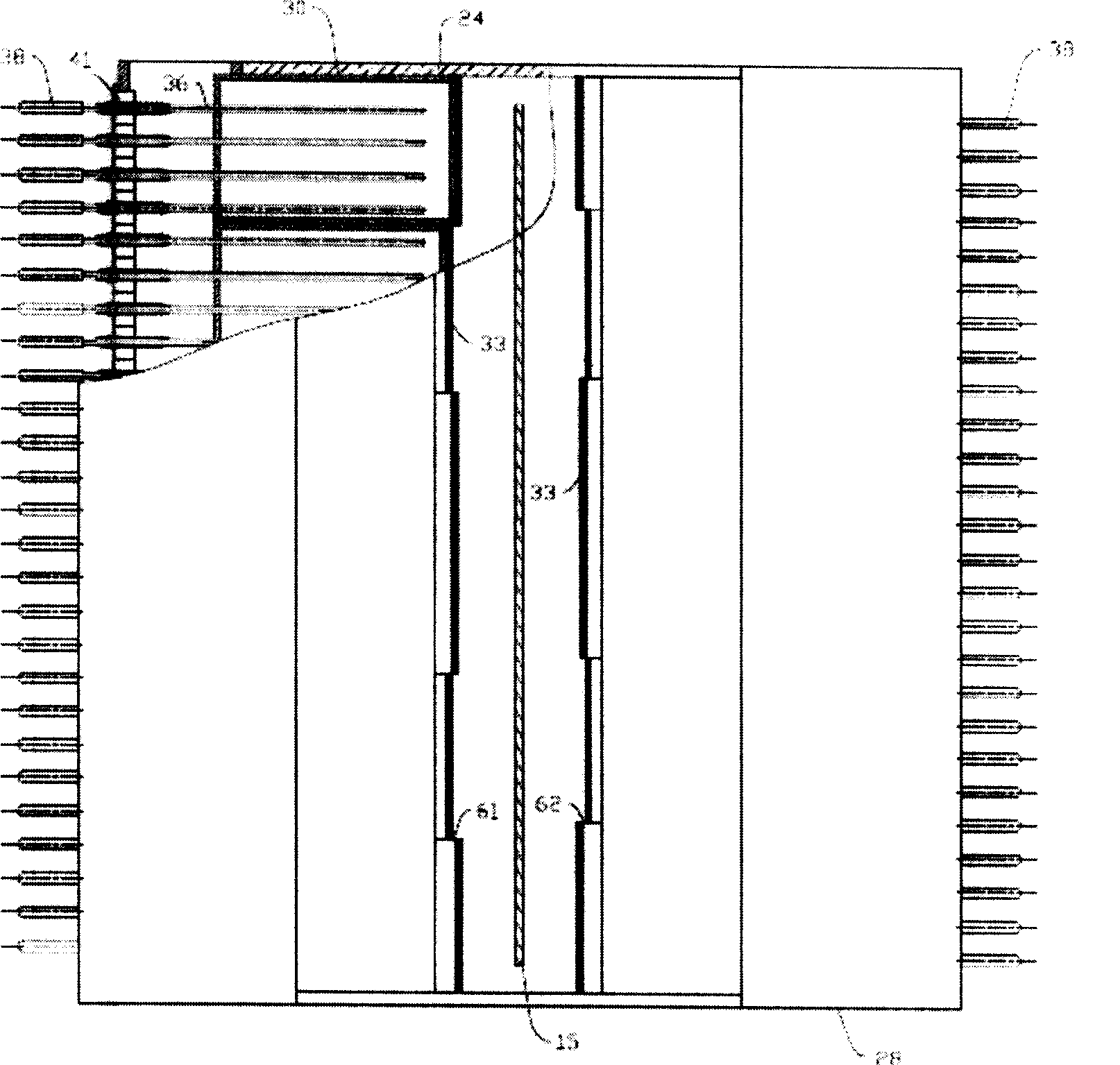

[0032] figure 2 One embodiment of the invention is shown. In this embodiment, the molten glass made according to the glass formula in the patent CN200510007338.0 flows down the overflow brick, and converges at the root of the overflow brick to form a glass plate with a width of 1540 mm and a thickness of 0.7 mm; there are 5 glass plates on each side Closed cavities, their lengths in the width direction of the glass plate are 150mm, 350mm, 600mm, 350mm, 190mm, 10 in total on both sides. The closed cavities of 150mm and 190mm are facing each other, so that the contact between two adjacent closed cavities on both sides of the glass plate will not be facing directly. The cooling pipes in the closed cavity have an inner diameter of 10mm and are arranged at a distance of 60mm. The adjustment distance of each pipe in the direction of the glass plate is 100mm, and the adjustment distance of the pipes in the direction of the width of the glass plate is + / -30mm. There is cooling wate...

Embodiment 2

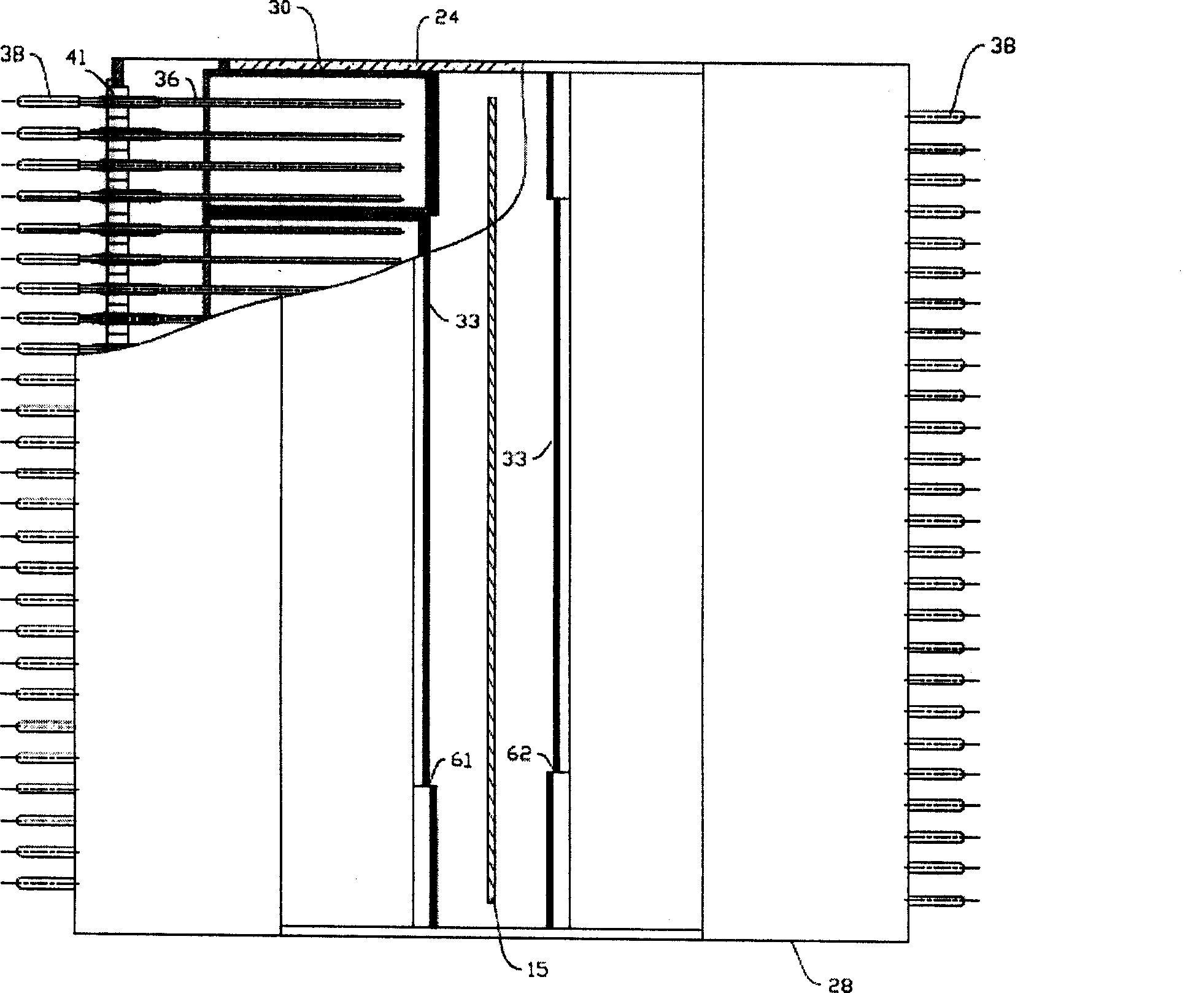

[0034] image 3 Another embodiment of the invention is shown. In this embodiment, the molten glass made according to the glass formula in patent CN200510007338.0 flows down along the overflow brick, and converges at the root of the overflow brick to form a glass plate with a width of 1540mm and a thickness of 0.7mm; there are 3 glass plates on each side Closed cavities, their lengths in the width direction of the glass plate are 150 mm, 1300 mm, and 190 mm respectively, and there are 6 in total on both sides. The closed cavities of 150mm and 190mm are facing each other, so that the contact between two adjacent closed cavities on both sides of the glass plate will not be facing directly. The cooling pipes in the closed cavity have an inner diameter of 10mm and are arranged at a distance of 60mm. The adjustment distance of each pipe in the direction of the glass plate is 100mm, and the adjustment distance of the pipes in the direction of the width of the glass plate is + / -30mm....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com