Double-clutch device used for double-clutch transmission

A dual clutch and transmission technology, applied in clutches, fluid drive clutches, mechanical drive clutches, etc., can solve problems such as high resistance torque and high complexity, achieve low resistance torque, reduce component complexity, and eliminate leakage.

Inactive Publication Date: 2007-09-05

GETRAG GETRIEBE & ZAHNRADFABRIK HERMANN HAGENMEYER GMBH & CO KG

View PDF3 Cites 39 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The disadvantage of a dual clutch arrangement of the type described is that it has a rather high complexity and produces a high drag torque

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

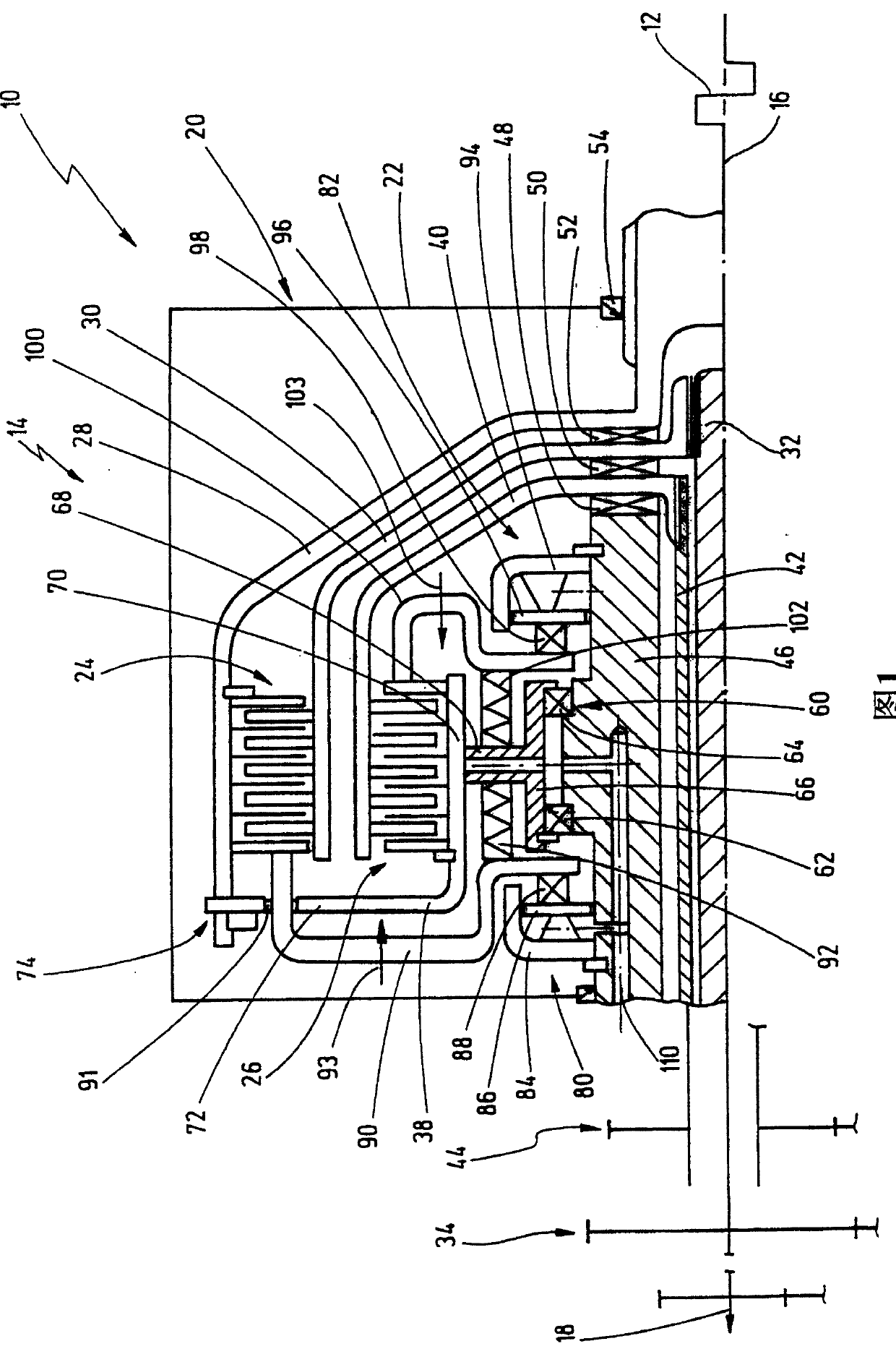

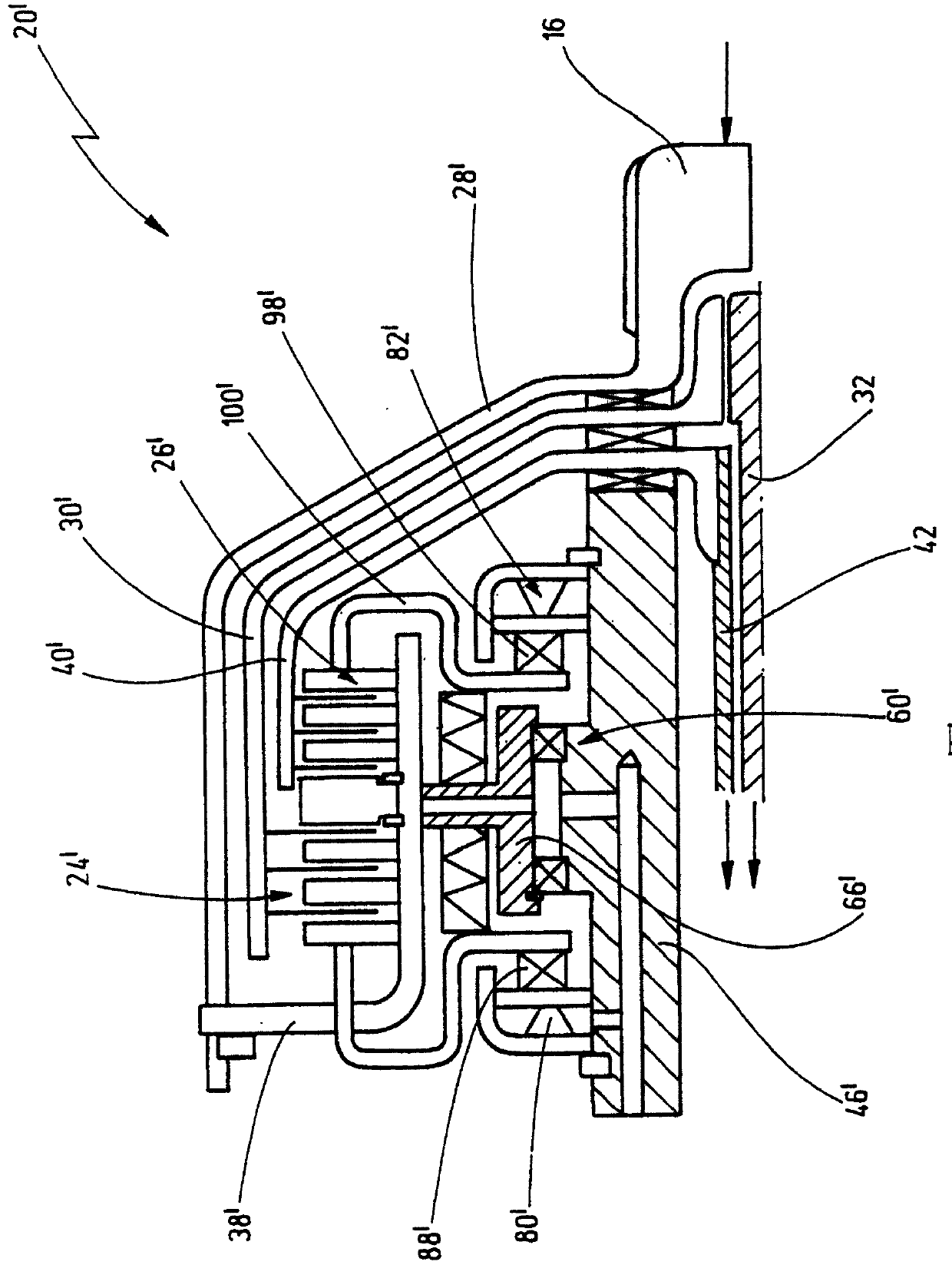

A double clutch device (20) for a double clutch transmission (14) is provided; the double clutch device comprises an input shaft (16), a first friction clutch (24), a second friction clutch (26), two output shafts (32, 42), a hub (46) fixed on the shell, a first piston / cylinder unit (80) fixed on the shell, and a second piston / cylinder unit (82) fixed on the shell; wherein, the input elements (28, 38) of the friction clutches (24, 26) are connected to the input shaft (16), and the output elements (30, 40) of the friction clutches (24, 26) are connected to one of the two output shafts (32, 42) in all cases, and the friction clutches (24, 26) can utilize the piston / cylinder units (80, 82) fixed on the shell to exercise actuation in all cases; the double clutch device further comprises axle bearings (88, 98), wherein, at least one of the input elements (28, 38) utilizes a radial bearing unit (60) to mount to the hub (46) fixed on the shell in a rotary manner.

Description

technical field The invention relates to a dual clutch device for a dual clutch transmission, the dual clutch device has an input shaft, a first friction clutch, a second friction clutch, two output shafts, a hub fixed to the housing, a hub fixed to the housing A first piston / cylinder arrangement on the housing, and a second piston / cylinder arrangement fixed to the housing, the input element of the friction clutch is connected to the input shaft, the output element of the friction clutch is in each case Connected to one of the two output shafts and the friction clutch can in all cases be actuated by means of one of the piston / cylinder arrangements fixed on the housing, the dual clutch arrangement also has an axial bearing. Background technique A dual clutch arrangement of the type described is known from DE 10 2004 061 020 A1. A dual clutch transmission has a dual clutch arrangement and two subtransmissions. Said partial transmissions are generally designed as spur gear ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F16D21/06F16D25/06F16D25/10F16D25/12

CPCF16D25/10F16D25/082Y02T10/76F16D2021/0661F16D21/06

Inventor 汉西·格伦普利尼库诺·弗罗纽斯

Owner GETRAG GETRIEBE & ZAHNRADFABRIK HERMANN HAGENMEYER GMBH & CO KG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com