Automotive glass washer arrangement

一种汽车玻璃、洗涤装置的技术,应用在车辆的清洗、车辆保养、运输和包装等方向,能够解决起动困难等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

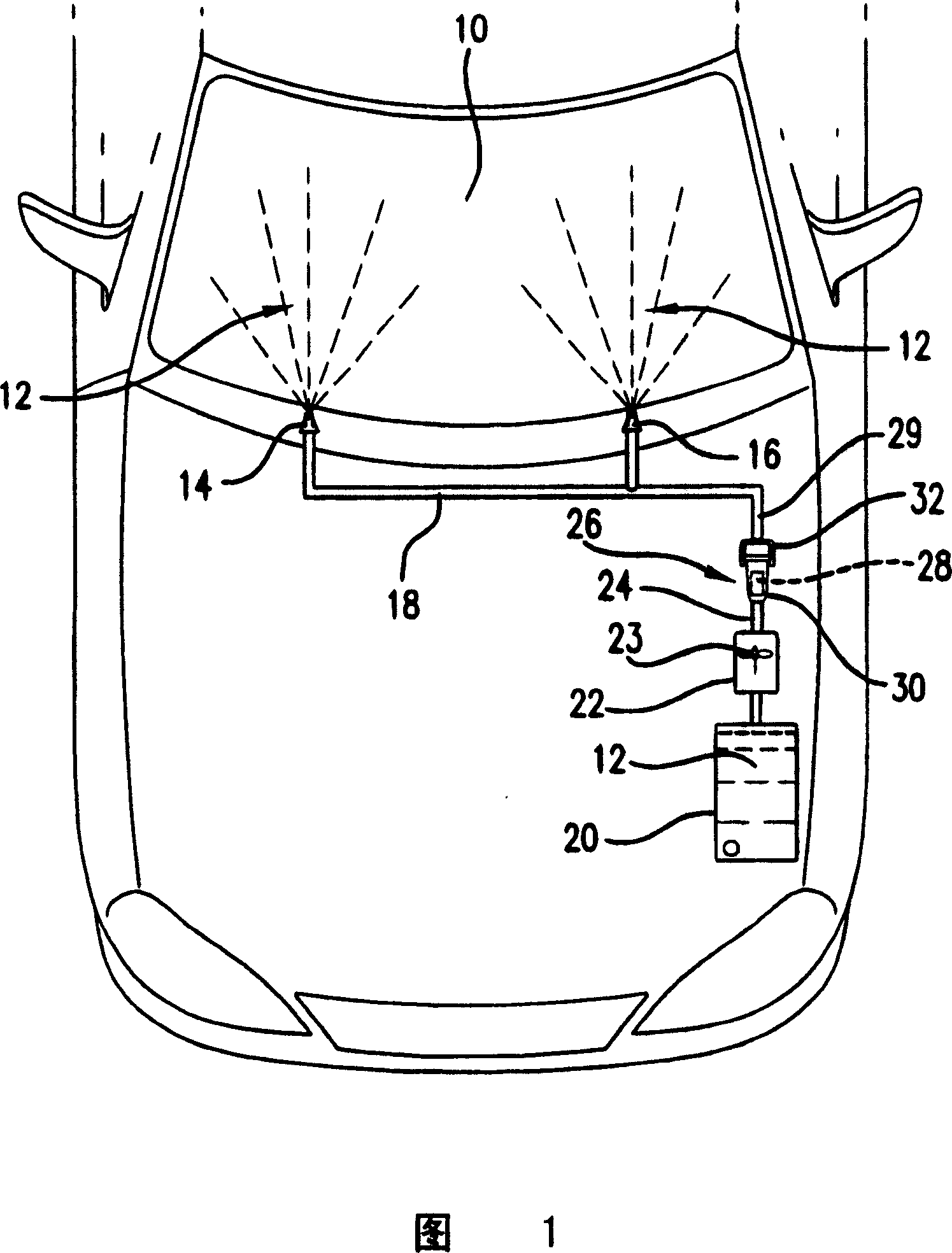

[0017] Referring now to FIG. 1 , automotive glass, such as a windshield 10 , is washed by a washer fluid 12 sprayed onto the glass through a pair of nozzles 14 and 16 . The nozzles 14 and 16 are connected in series via a fluid line 18 , which in turn is supplied with washing liquid from a water storage container 20 . The reservoir 20 is connected to a wash pump 22 which uses an impeller 23 to pump the wash liquor 12 through a first fluid line in the form of a first hose 24 to a fluid coupling 26 constructed in accordance with the principles of the present invention. Fluid coupling 26 includes a filter 28 for removing impurities, including impeller 23 passing through wash pump 22 to hose 24 . Filter 28 is preferably cylindrical and is preferably made of plastic or stainless steel. A second fluid line in the form of a second hose 29 conveys the filtered washing liquid 12 to the fluid line 18 connected to the nozzles 14 and 16 .

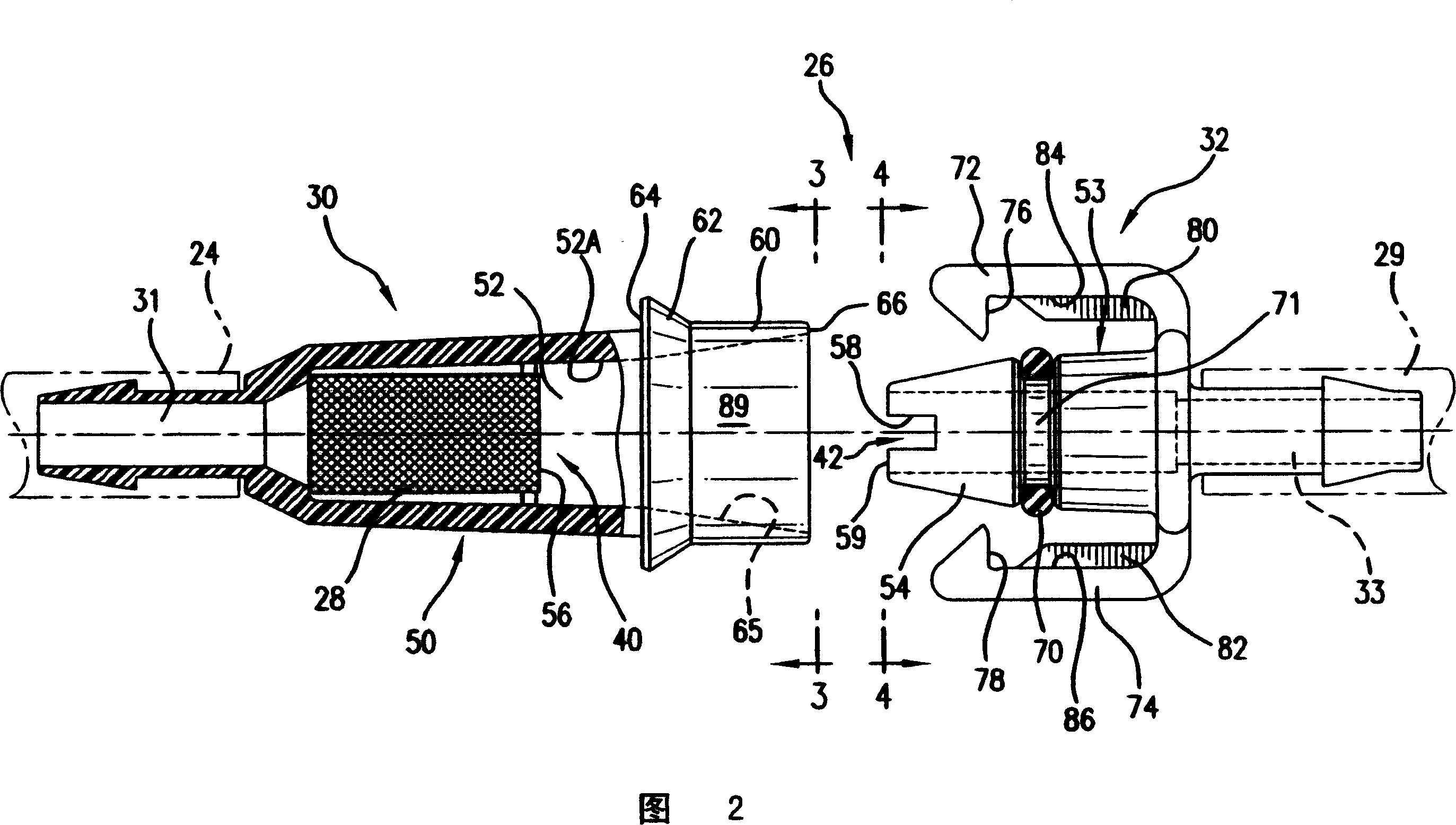

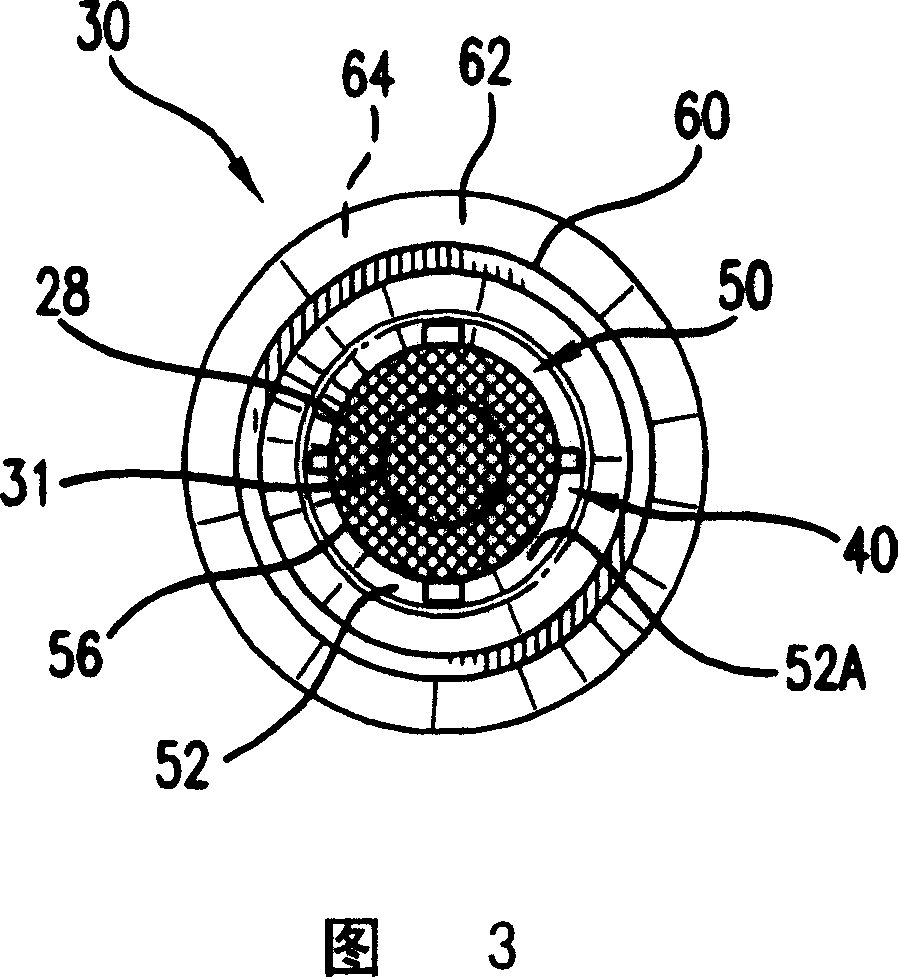

[0018] Referring now to FIG. 2, according to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com