Apparatus for automatically compensating for clearance of support yoke in rack-and-pinion steering system

A technology of steering system and automatic compensation, which is applied in the direction of transmission, friction transmission, transmission parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Hereinafter, preferred embodiments of the present invention will be described with reference to the accompanying drawings. In the following description and drawings, the same reference numerals are used to denote the same or similar components, and thus repeated descriptions of the same or similar components will be omitted.

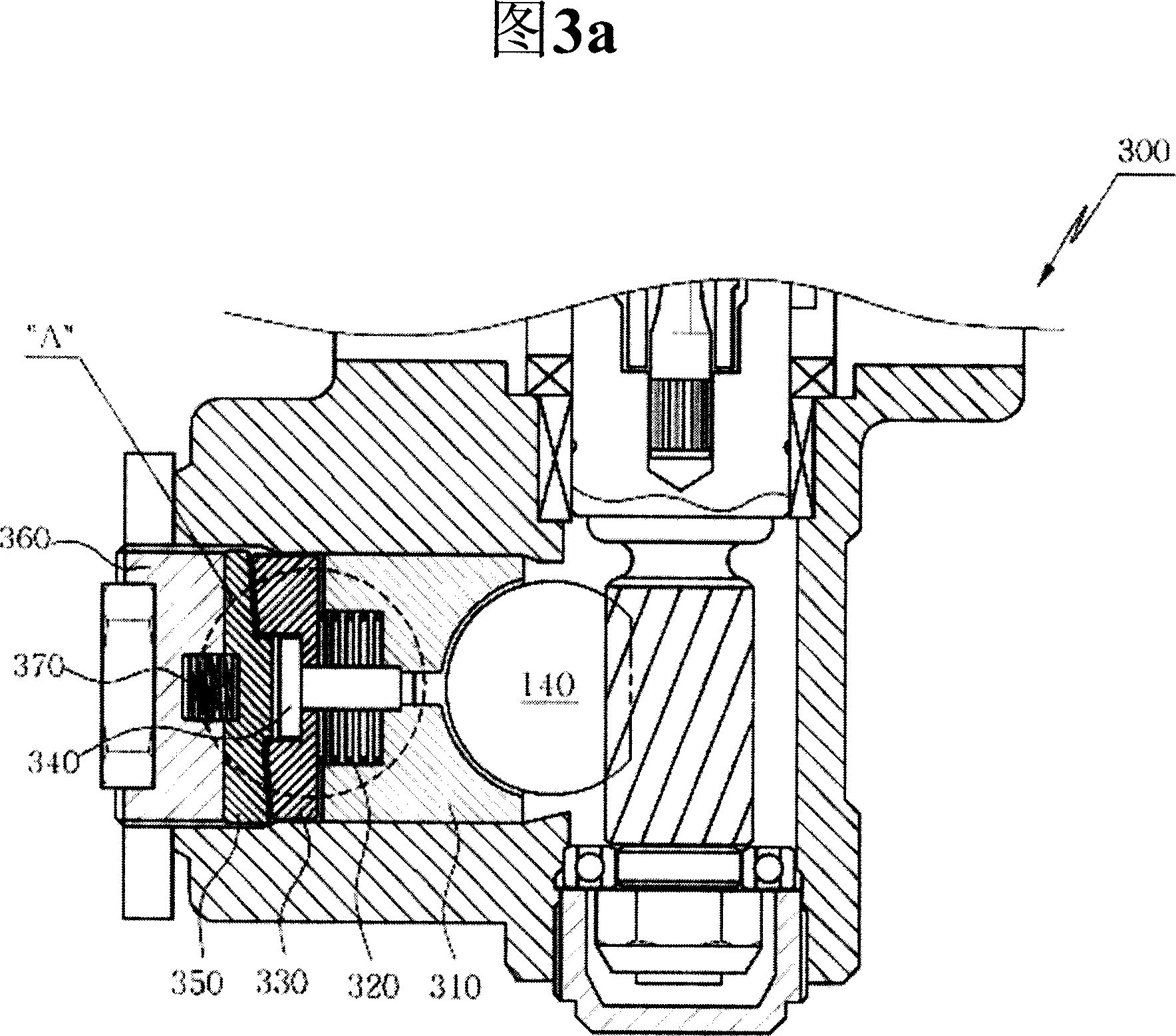

[0026] Fig. 3a is a cross-sectional view of the device for automatically compensating the clearance of a support yoke according to a preferred embodiment of the present invention, and Fig. 3b partially enlarges part A shown in Fig. 3a.

[0027] The device 300 for automatically compensating the backlash of a support yoke according to a preferred embodiment of the present invention includes: a support yoke 310; a yoke spring 320; a first cam 330; a fixing element 340; a second cam 350; Torsion spring 370.

[0028] The yoke plug 360 has the same material and shape as a conventional yoke plug except for a fixing recess 315 formed therein for mounting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com