Method of directly leaching zinc ore concentrate or low grade mixing zinc ore under normal pressure and alkaline condition

A zinc concentrate, low-grade technology, applied in the direction of improving process efficiency, can solve the problems of limited applicability, high material requirements, high cost, etc., and achieve good social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

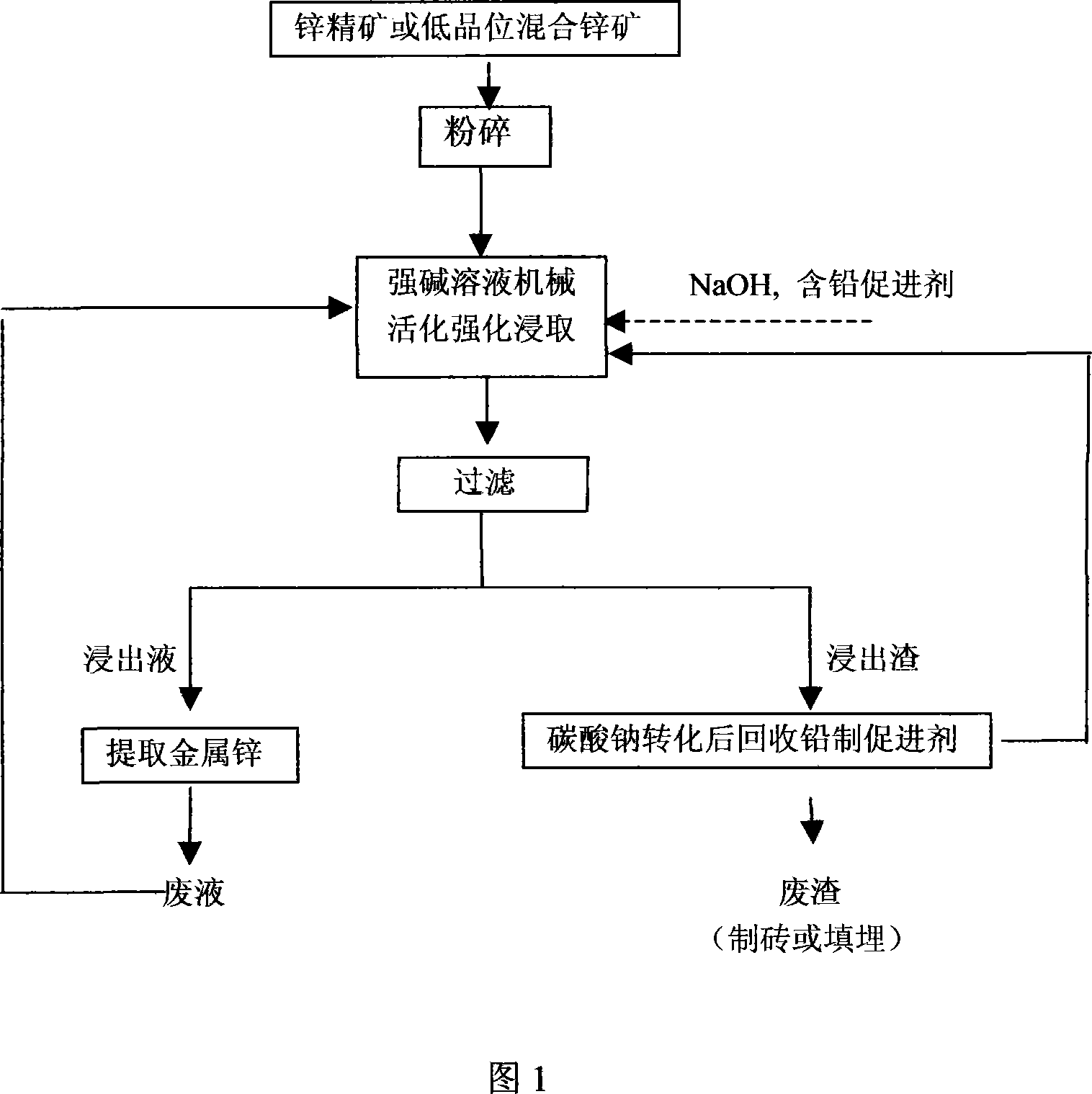

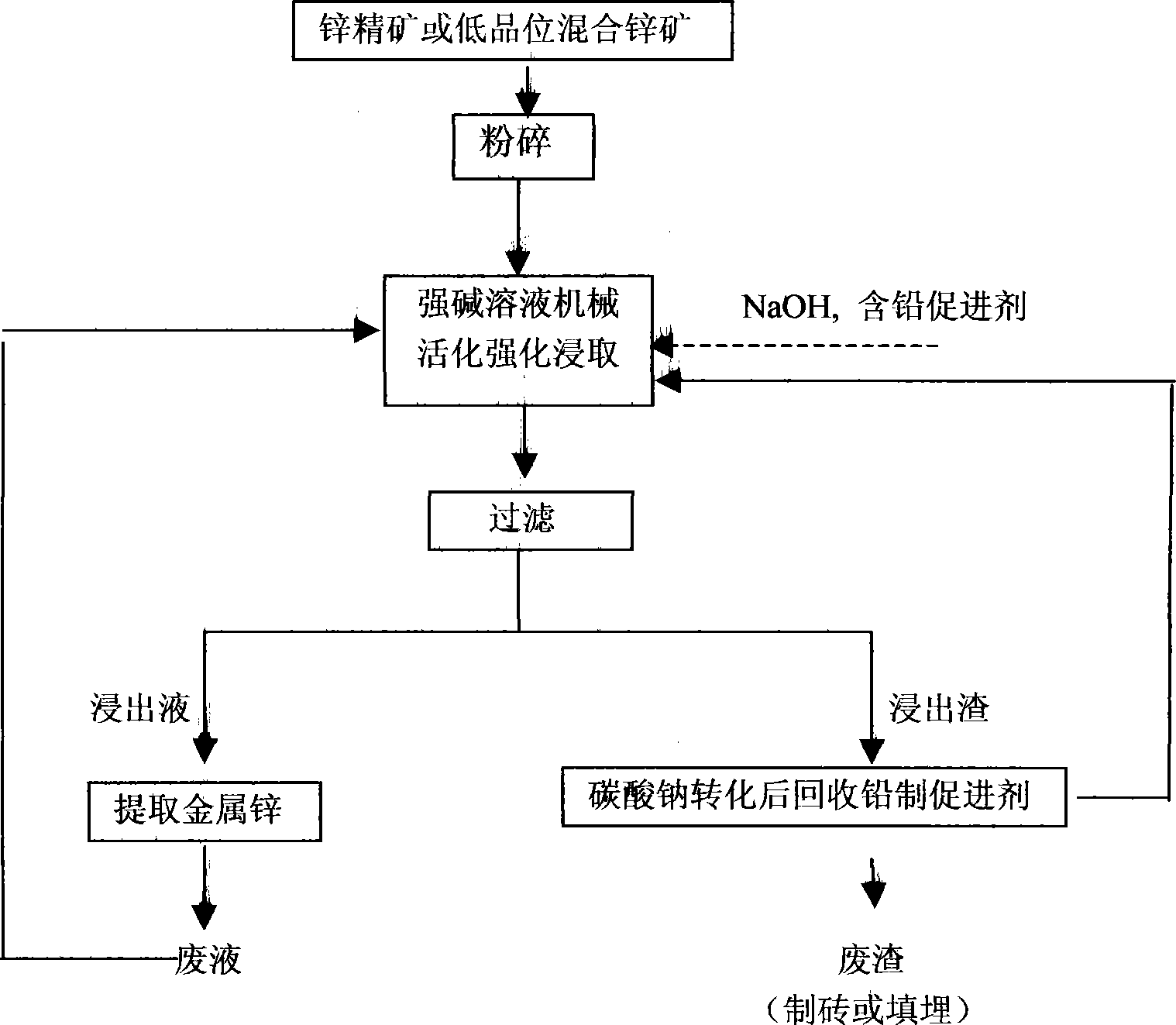

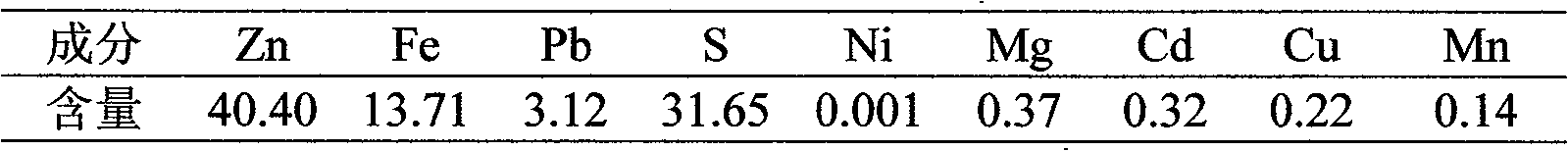

[0018] Please refer to the attached figure 1 . The zinc concentrate produced in Lancang, Yunnan is used as raw material, and its chemical composition is shown in Table 1.

[0019] Table 1 Chemical composition of Lancang zinc concentrate

[0020]

[0021] 100g of above-mentioned zinc concentrate raw material is pulverized to 0.5-1mm, joins in the stirred mill reactor, adds 1-1.5L concentration simultaneously and is 2-8M industrial caustic soda solution and 50-150g leaded leaching reaction accelerator (is the Commercial-grade lead carbonate and lead oxide are mixed in any proportion), and raw materials: activation medium (corundum ball or stainless steel ball) with an activation medium ratio of 1:5 (mass ratio), and the leaching temperature is controlled at 70-90°C , under the stirring condition of 300-600 rev / min, react for 60min. The extraction rate of zinc in zinc concentrate is 86.5%. Filter, wash the leaching residue (filter residue) with water, and use the washing ...

Embodiment 2

[0023] The zinc concentrate in Mengzi, Yunnan is used as raw material, and its chemical composition is shown in Table 2.

[0024] Table 2 Chemical composition of Yunnan Mengzi zinc concentrate

[0025]

[0026] 100g of the above-mentioned zinc concentrates are pulverized to 0.5-1mm and added to the stirred mill reactor, and 0.8-1.2L concentration of 2-8M industrial caustic soda solution and 40-100g lead-containing leaching reaction accelerator (commercially available industrial grade) are added simultaneously. lead sulfate and lead peroxide mixed in any proportion), and the activation medium (corundum ball or stainless steel ball) with the mass ratio of raw material:activation medium (1:5~1):20, and the leaching temperature is controlled at 80-90 °C, react for 90 minutes under the stirring condition of 300-600 rpm. The extraction rate of zinc in zinc concentrate is 89.2%. Filter, wash the filter residue with water, and keep the washing water for the leaching process. Mea...

Embodiment 3

[0028] The low-grade mixed zinc ore in Xinjiang is used as raw material, and its chemical composition is shown in Table 3. According to phase analysis, ZnS accounts for 40% of the zinc content, ZnO and ZnCO 3 60%.

[0029] Table 3 Chemical composition of low-grade mixed zinc deposits in Xinjiang

[0030]

[0031] 100g of the above-mentioned low-grade mixed zinc ore pulverized to 0.5-1mm is added in the stirring mill reactor, and 0.2-0.6L concentration is added at the same time as 2-8M industrial caustic soda solution and 5-25g lead-containing leaching reaction accelerator (according to any The mixture of lead nitrate and trilead tetroxide mixed in proportion), and raw material: activation medium is 1:10 (mass ratio) of corundum ball or stainless steel ball activation medium, the leaching temperature is controlled at 70-80 ° C, at 300-600 The reaction was carried out for 120 min under the stirring condition of rev / min. The extraction rate of zinc in zinc concentrate is 81...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com