Method for producing water coal slurry

A coal-water slurry and slurry storage technology, which is applied in the petroleum industry, liquid carbon-containing fuel, fuel, etc., can solve the problems of high maintenance costs, large floor space, and high manufacturing costs, and achieve low equipment manufacturing costs and low floor space. The effect of less and no dust pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

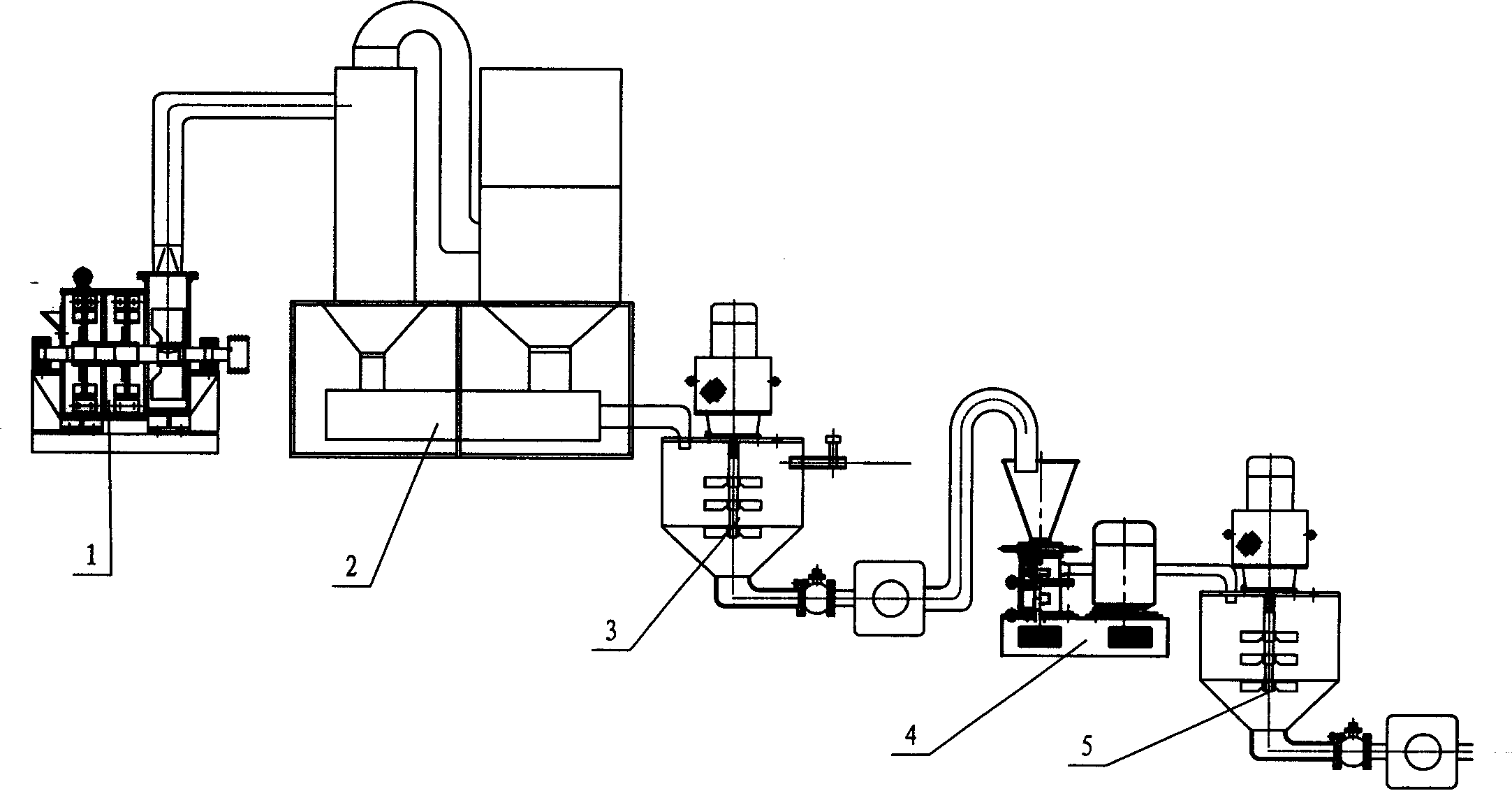

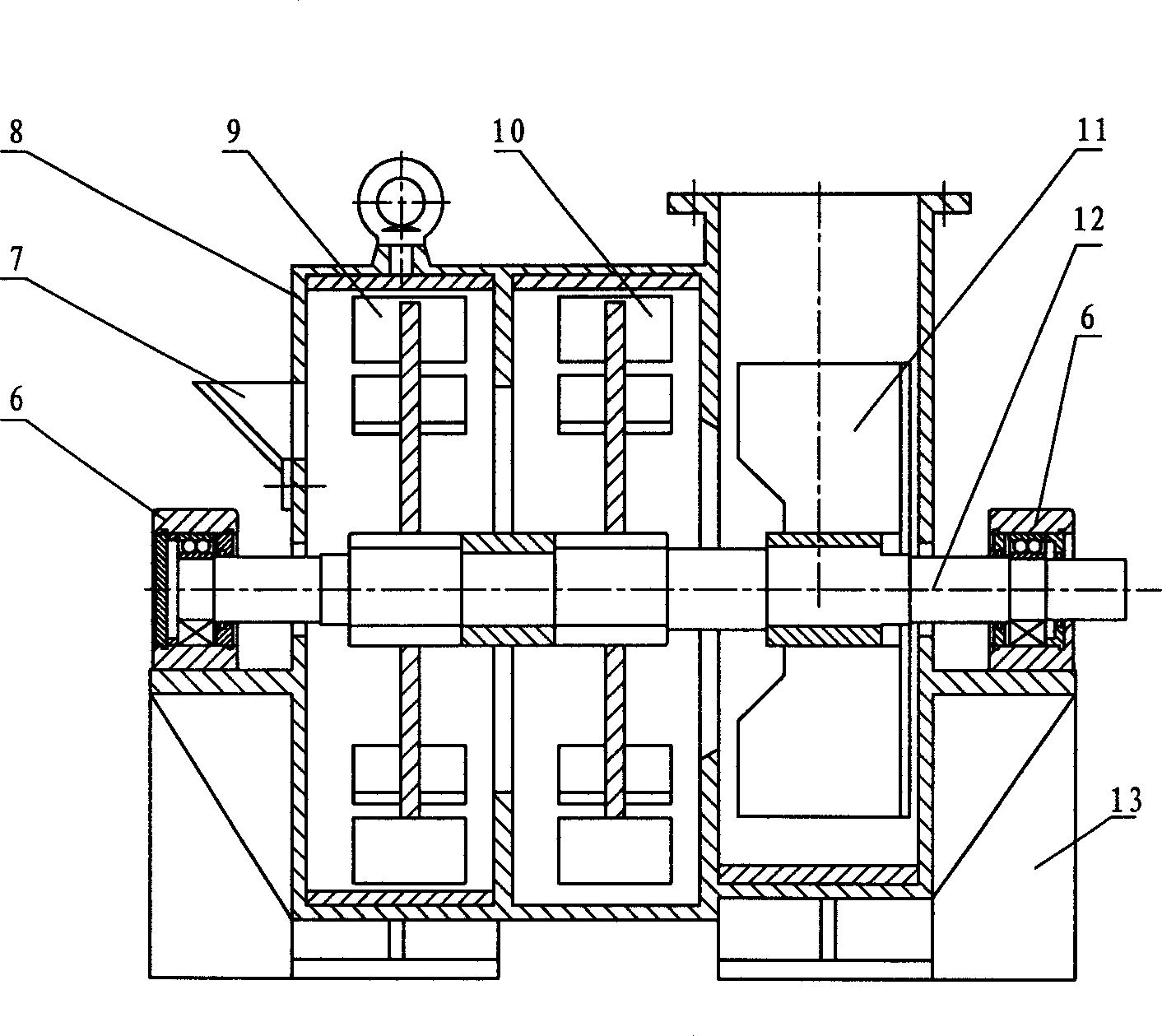

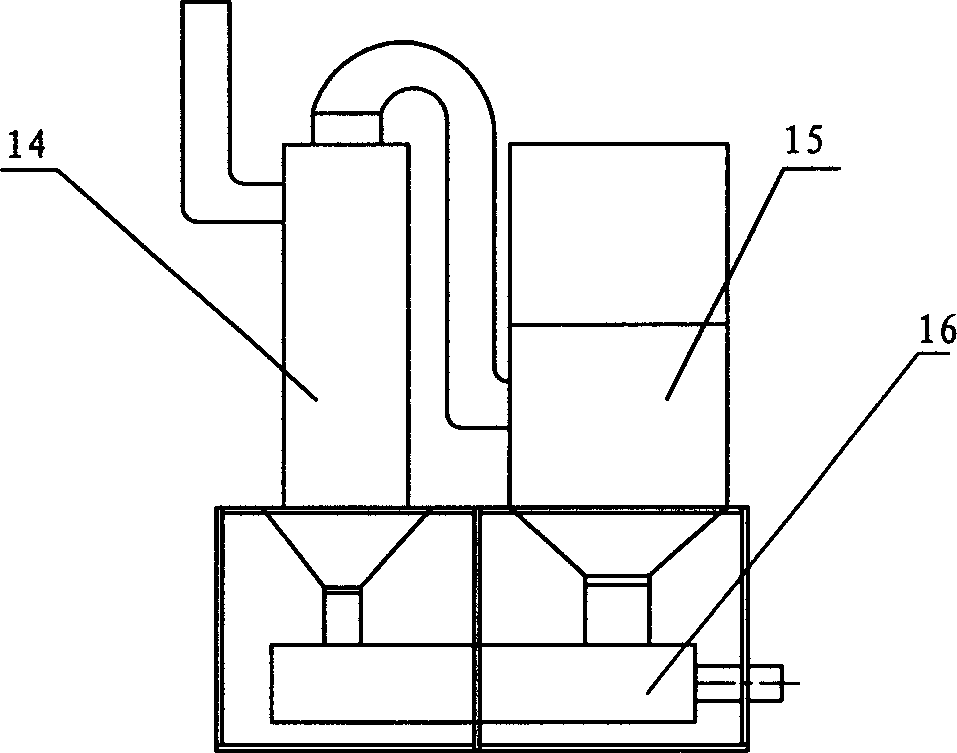

[0012] According to attached Figure 1-4 The technical process of the present invention and the specific structure of the equipment used are described in detail.

[0013] The technological process of the invention is crushing→collecting→premixing→homogenizing→storage. Among them, the pulverizing process adopts a pulverizer 1 with multi-stage crushing and optional functions. The collection process adopts a dust collector 2 composed of a cyclone dust collector 14 , a bag dust collector 15 and a feeding device 16 connected to each other. The mixing process adopts a premix mixing tank 3 and a homogeneous mixing colloid mill 4 with an agitator 17 . A dust collector 2 is provided between the pulverizer 1 and the mixing tank 3 . Coal pulverizer 1 (patent applied for separately) comprises the lower body 13 that is assembled with bearing block 6, the upper body 8 that has feeding hopper 7 and parts such as transmission shaft 12, hammer plate, fan 11 that assemble in it. Wherein ham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com