A kind of production method of plasma enhanced coal-to-acetylene

A production method and plasma technology, applied in the fields of chemical instruments and methods, organic chemistry, hydrocarbons, etc., can solve the problems of large dust entrainment in the product gas, blockage of the plasma reactor, and inability to carry out work, so as to save energy. , avoid energy consumption, avoid the effect of a large number of inclusions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

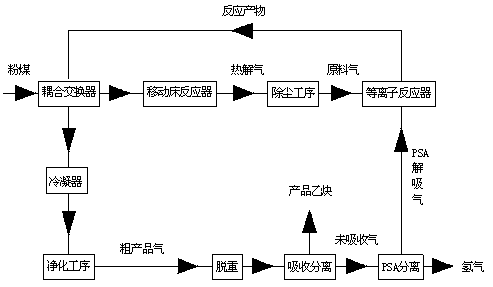

Image

Examples

Embodiment 1

[0025] Put pulverized coal into the moving bed at a rate of 12 kg / h, carry out medium-temperature pyrolysis at 800°C, and release hydrocarbon-rich pyrolysis gas. After the pyrolysis gas is filtered and dedusted by cyclone + ceramics, semi-coke and dust content are 0.05 mg / Nm 3 Pyrolysis raw material gas, hydrogen is introduced into a plasma generator with a power of 250kw as a flow gas to form a hydrogen plasma jet, and the reaction of plasma pyrolysis to acetylene is carried out at 1700 ° C. The reaction product is heat exchanged through a coupling exchanger, and the reaction product is cooled and released. The heat is used to preheat the pulverized coal, and then heated to 800°C for medium temperature pyrolysis. After the reaction product is cooled to 50°C, it enters the purification process and uses a silica gel adsorbent loaded with 3.8% (wt) sodium ions to remove impurities such as carbon black, sulfur, phosphorus, fluorine, chlorine, etc., and the purified gas is absorbe...

Embodiment 2

[0027] Put pulverized coal into the moving bed at a rate of 12 kg / h, carry out medium-temperature pyrolysis at 800°C, and release hydrocarbon-rich pyrolysis gas. After the pyrolysis gas is filtered and dedusted by cyclone + ceramics, semi-coke and dust content are 0.05 mg / Nm 3 Pyrolysis raw material gas, hydrogen is introduced into a plasma generator with a power of 250kw as a flow gas to form a hydrogen plasma jet, and the reaction of plasma pyrolysis to acetylene is carried out at 1700 ° C. The reaction product is heat exchanged through a coupling exchanger, and the reaction product is cooled and released. The heat is used to preheat the pulverized coal, and then heated to 800°C for medium temperature pyrolysis. After the reaction product is cooled to 50°C, it enters the purification process to remove carbon black, sulfur, phosphorus, fluorine, chlorine and other impurities with silica gel adsorbent that does not support metal ions. The purified gas absorbs propadiene and vi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com