Accurate detecting method for cavity leakage of lithium-ion battery and device thereof

A lithium-ion battery and battery cavity technology, which is used in measuring devices, using liquid/vacuum for liquid tightness measurement, and measuring the acceleration and deceleration rate of fluids, etc. Detection and other problems, to achieve the effect of improving detection accuracy, simple structure, and improving detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

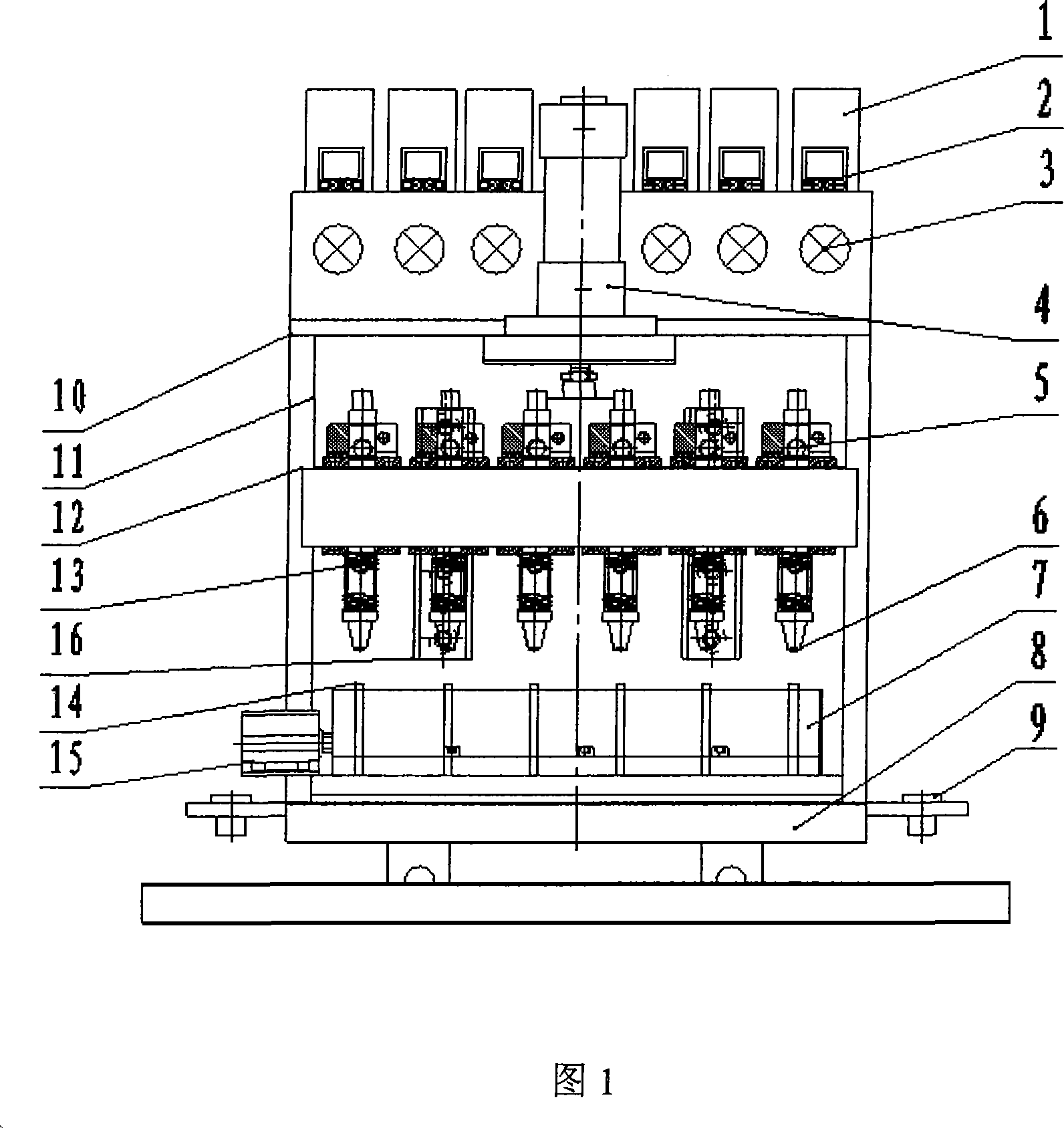

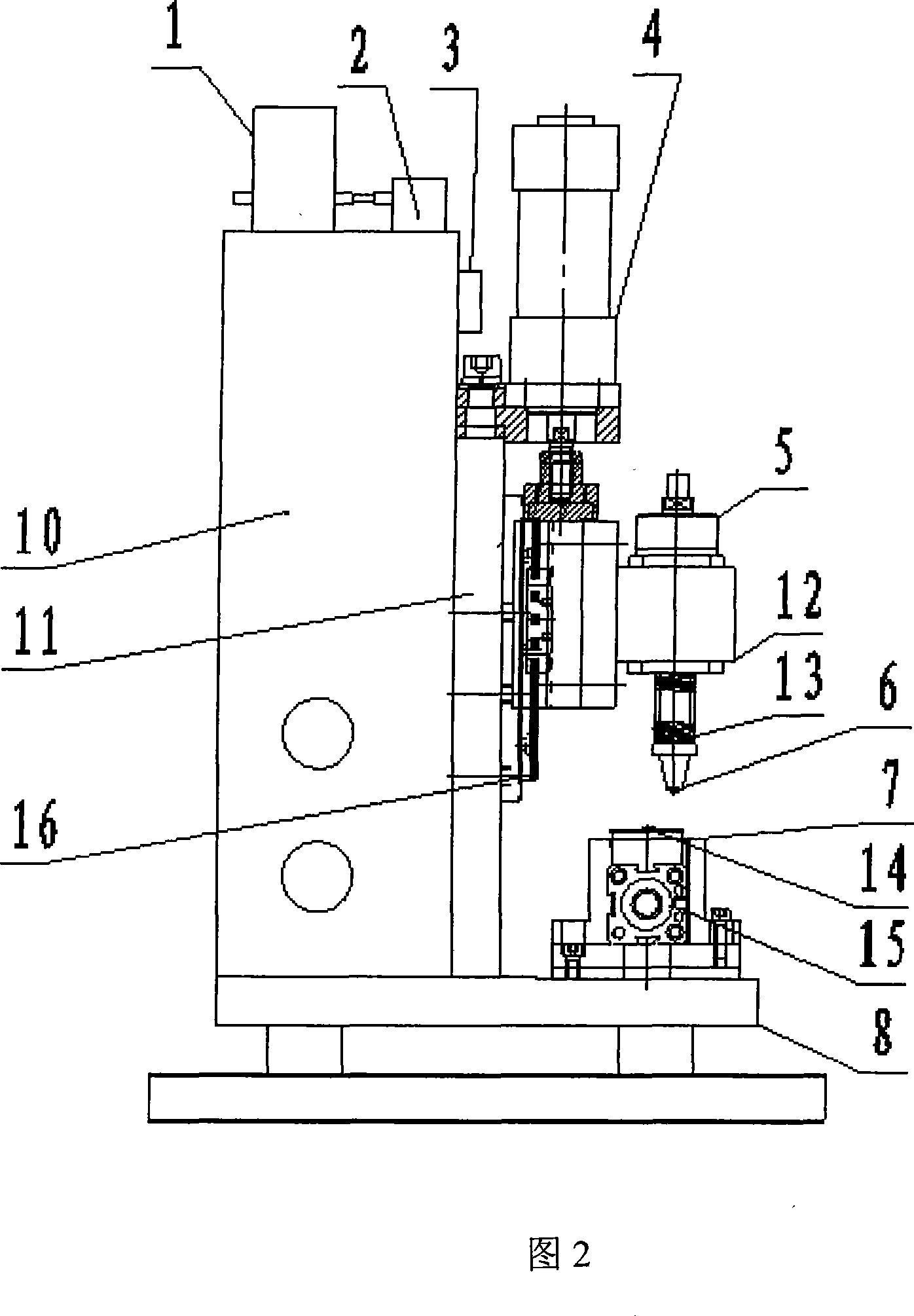

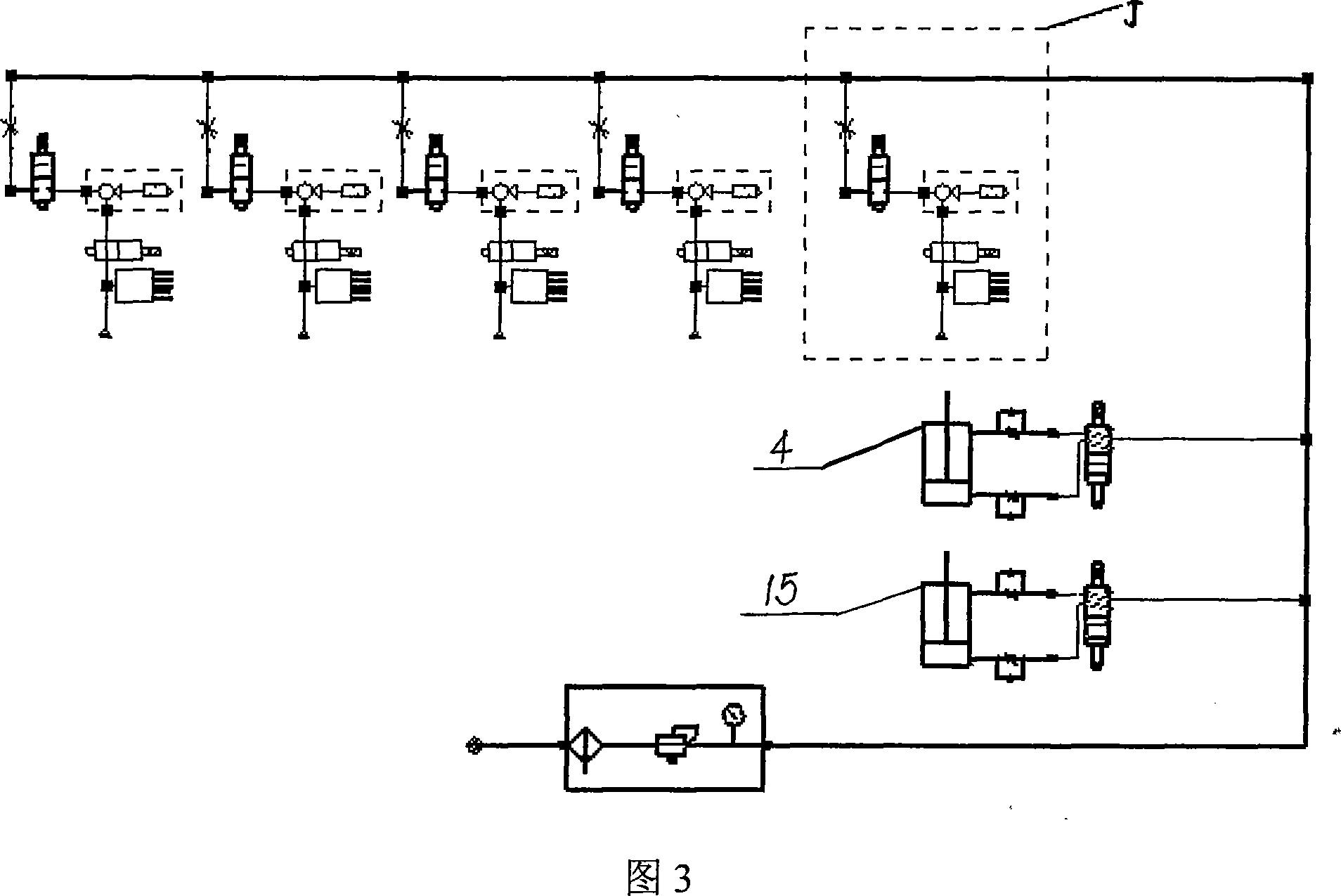

[0019] Below in conjunction with accompanying drawing and preferred embodiment, the specific embodiment, structure, feature of the method of the present invention and device thereof are described in detail as follows:

[0020] A precise detection method for lithium-ion battery cavity leakage, characterized in that the implementation steps are as follows:

[0021] (1) In the vacuuming stage, the time is controlled within T1: within 3 to 5 seconds, and the vacuum degree inside the battery cavity is pumped to a certain value P1; if the vacuum degree is within T1 time, the value of P1 cannot be reached , it means that the battery cavity has obvious leakage, which is judged as bad, where P1 is the set standard value: -75KPa~-95KPa;

[0022] (2) In the stage of maintaining balance, the time is controlled within T2: within 2-3 seconds, the seal of the battery cavity is kept, the vacuum degree is maintained, the gas path is stabilized, and interference is eliminated;

[0023] (3) In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com