Bisectional four-color offset press

A technology of offset printing machine and frame, which is applied in the field of four-color offset printing machine, which can solve the problem that the printing quality is difficult to meet higher requirements, the printing quality of offset printing machine is difficult to improve, and the end of printing paper is prone to curling, etc. problems, to achieve great practical and promotional value, easier balance of ink and wash, and better printing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

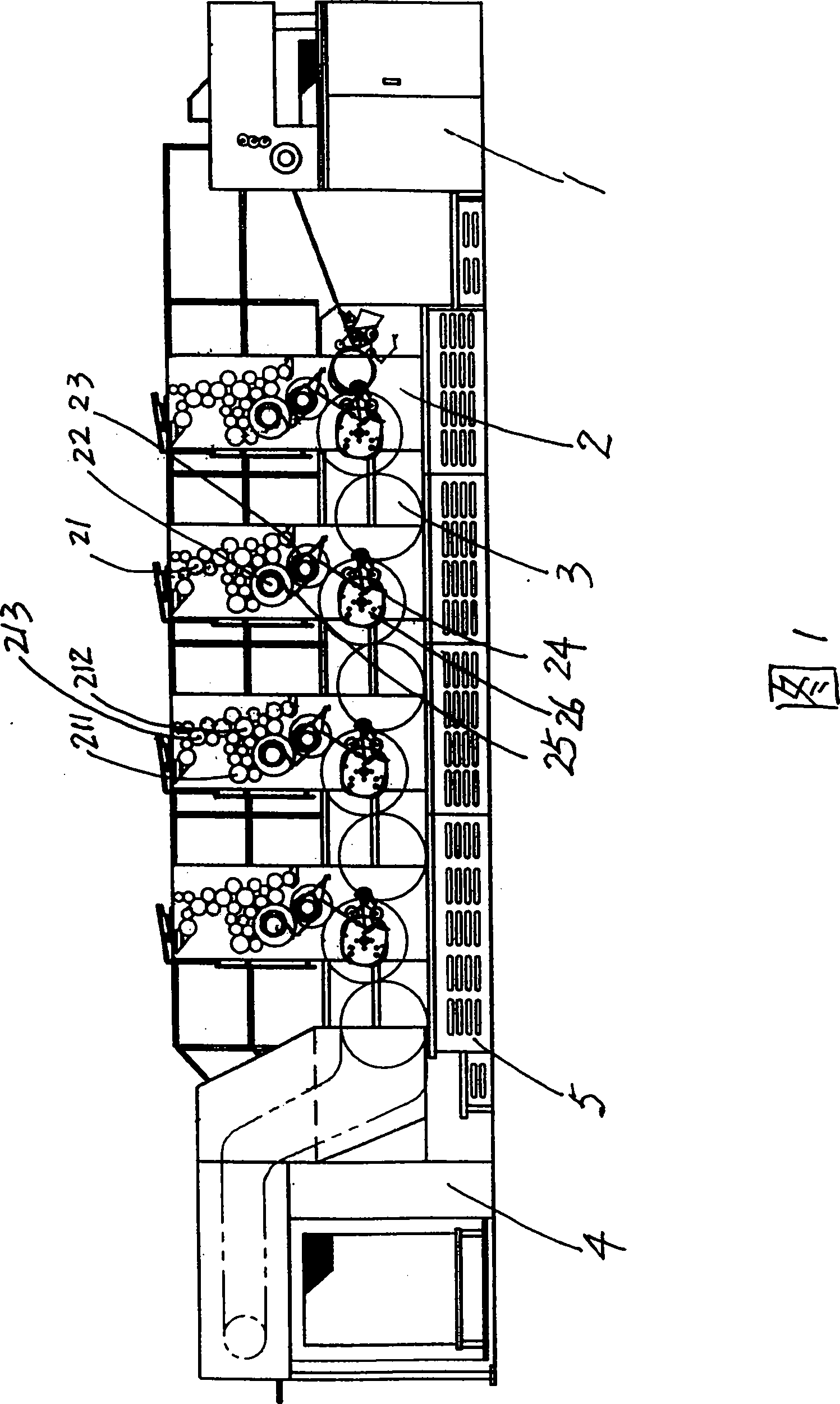

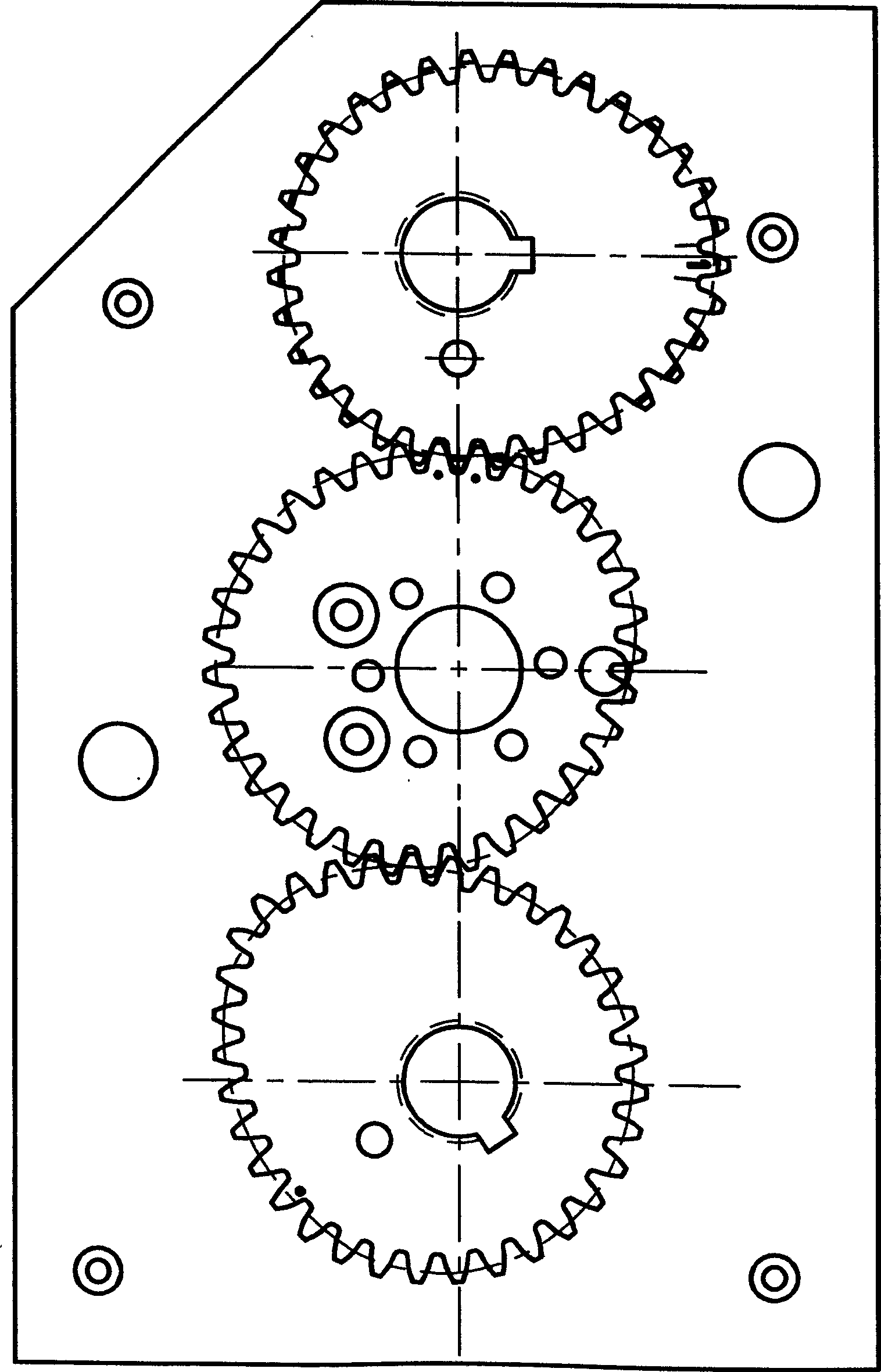

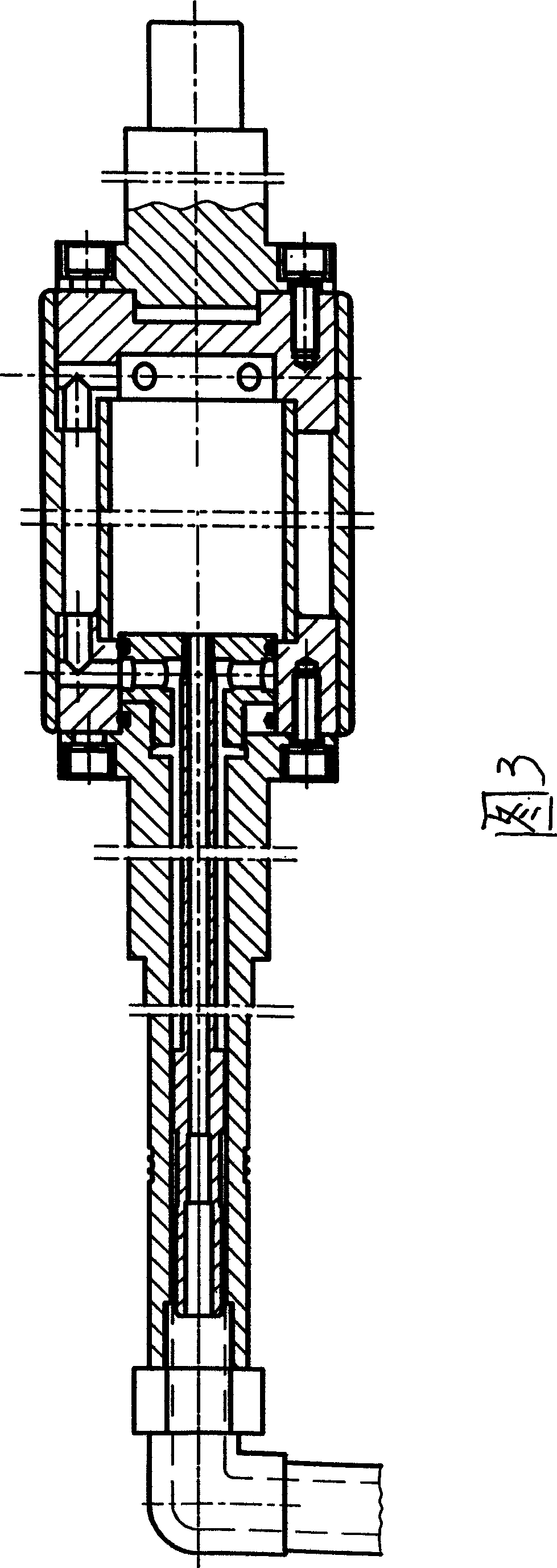

[0021] Refer to attached figure 1 , attached figure 2 , attached image 3 , attached Figure 6, the folio four-color offset printing machine of the present invention is composed of a paper feeding mechanism 1, four printing units 2, a paper transfer cylinder 3, a paper delivery mechanism 4, and a frame 5, and the four printing units 2 are respectively arranged on the frame 5 , between two adjacent printing units 2 are provided with a paper transfer cylinder 3 respectively. The paper feeding mechanism 1 is a mechanism that uses a set of non-circular gears to adjust the feeding speed of the paper. The paper feeding mechanism 1 of this embodiment uses two sets of non-circular gears that mesh with each other to periodically adjust the speed of the paper. Printing unit 2 is made up of ink system 21, plate cylinder 22, blanket cylinder 23, impression cylinder 24, follow-up mechanism 25, clutch pressure mechanism 26; 23 multiple diameters; the diameter of the paper transfer cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com