Shallow buried and underground excavated engineering project execution method and equipment thereof

A technology of shallow burial and underground excavation and engineering construction, which is applied to mining equipment, shaft equipment, earthwork drilling and mining, etc., and can solve problems such as excessive deformation and adverse effects of the surrounding environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

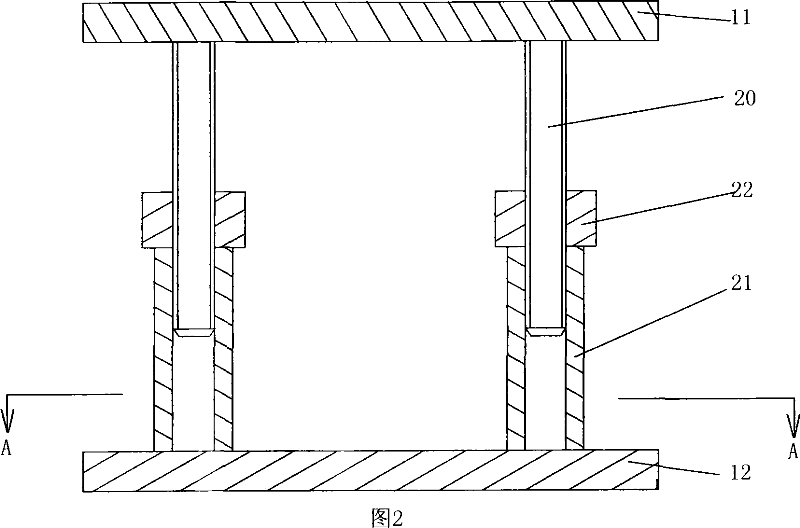

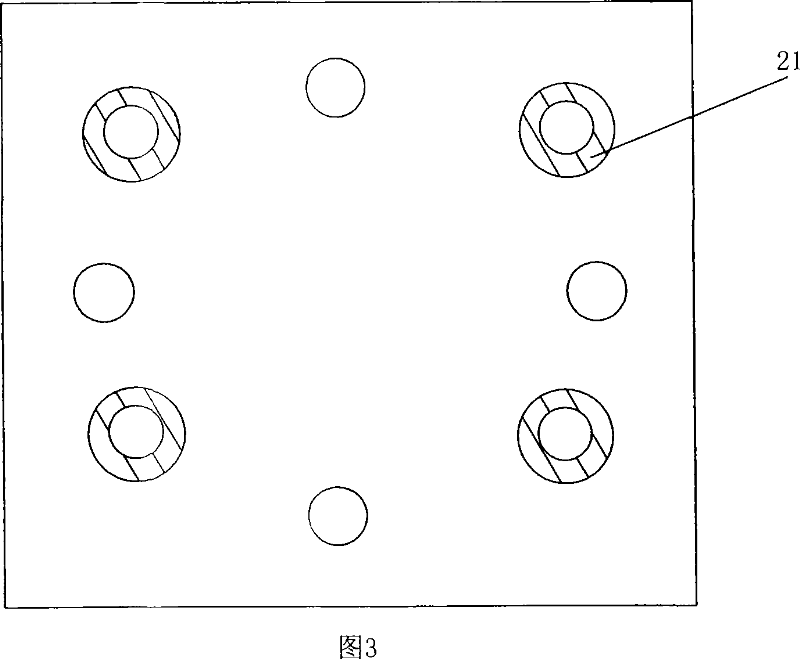

[0025] The present invention will be further described in conjunction with the embodiments and accompanying drawings.

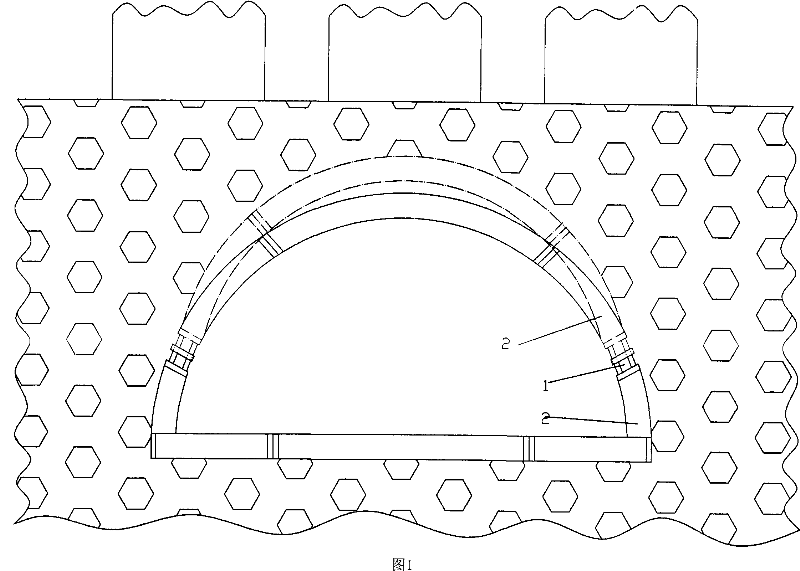

[0026] A construction method and equipment for a shallow buried excavation project. The construction method and steps include auxiliary construction, excavation, primary support, secondary mold injection, and primary support, including the following steps:

[0027] (1) Pre-spraying concrete, that is, hanging nets on the excavated tunnel section, and pre-spraying 5-10 centimeters of concrete, the three embodiments of the present invention are respectively 5 centimeters, 8 centimeters, and 10 centimeters.

[0028] (2) Install adjustable prestressed steel arches, that is, install adjustable prestressed steel arches at intervals of 0.5-1 meters on the excavated tunnel section. The three embodiments of the present invention are respectively 0.5 meters and 0.8 meters ,1 meter.

[0029] (3) Rigid pads, that is, rigid pads between the adjustable prestressed steel ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com