Noise preventing device of balance gear of crank

A technology for balancing gears and crankshafts, which is applied in the direction of hoisting devices, portable lifting devices, belts/chains/gears, etc. It can solve the problems of increased manufacturing costs, complicated structures, and inconvenient assembly, so as to improve the use efficiency, simplify assembly, and Reduce the effect of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

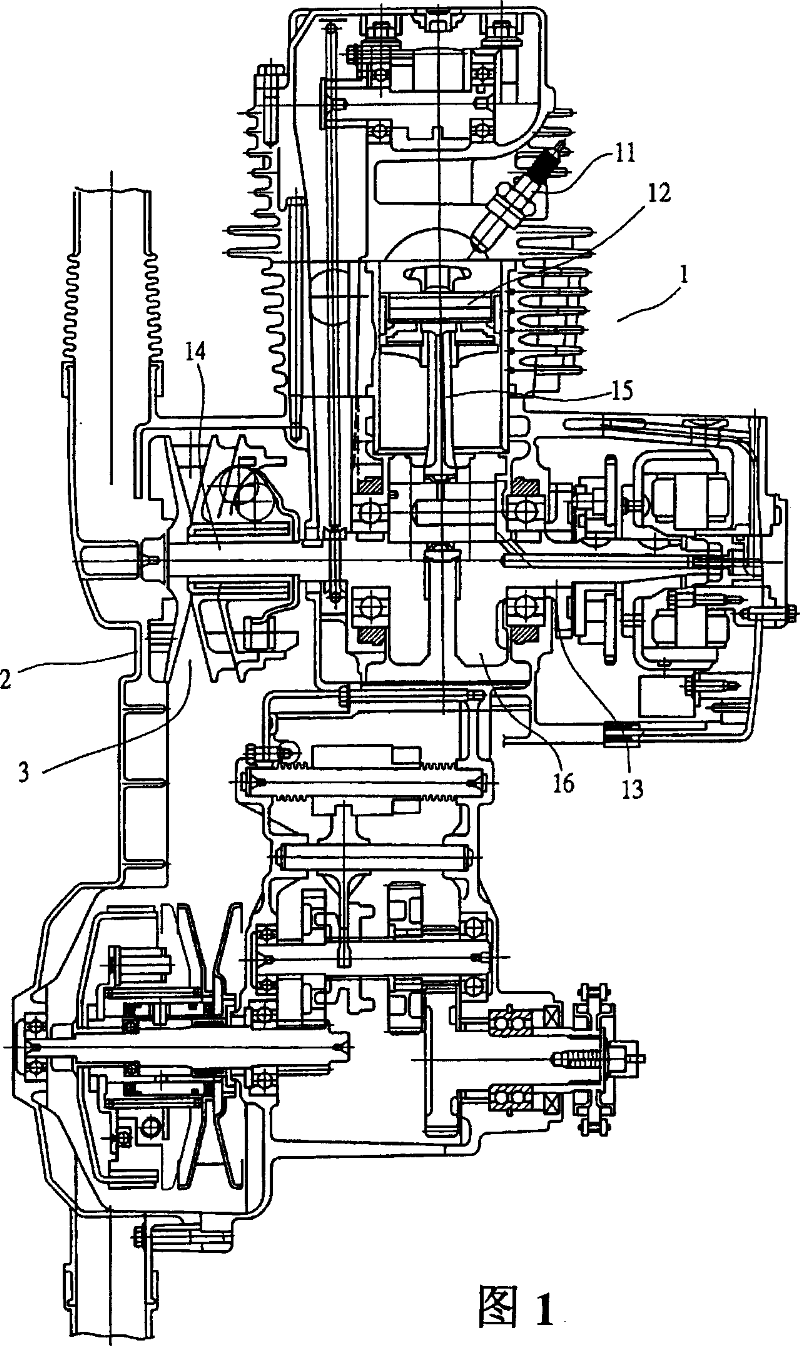

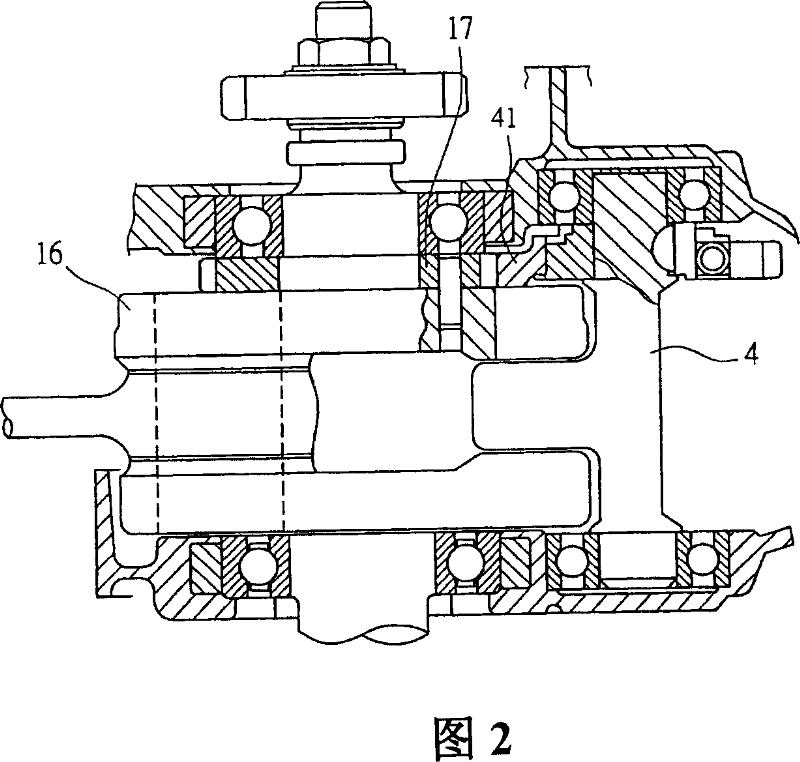

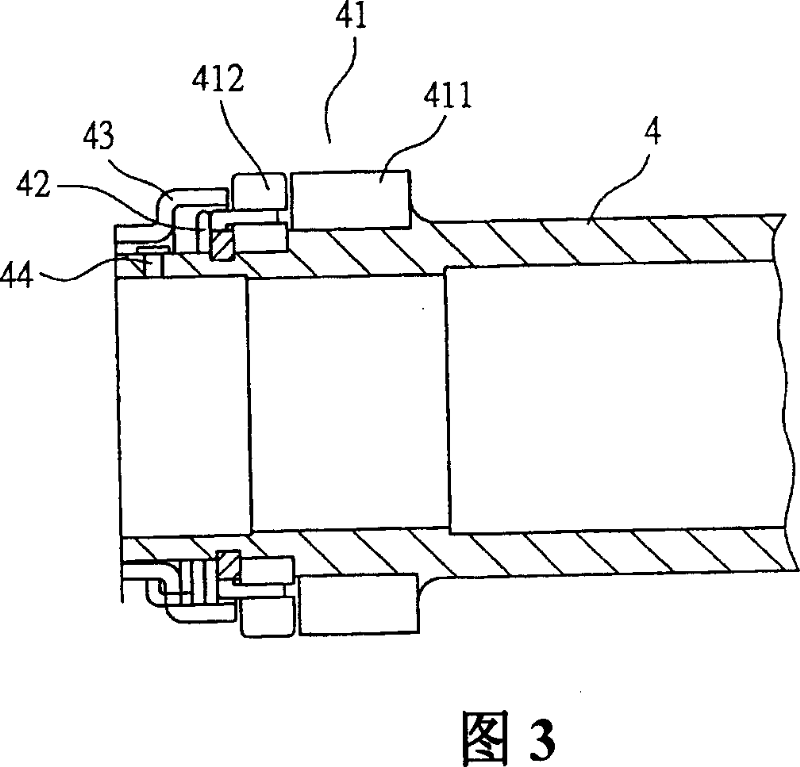

[0021] In order to be easier to understand the mechanism of the present invention and the effect that can be achieved, it is described as follows in conjunction with the drawings:

[0022] Its basic structure and mode of operation of the engine of the present invention are all the same as those known in the art, so the following detailed description of the implementation of the present invention will not repeat the relevant engine part, and will be stated first.

[0023] First, please refer to Figs. 4 and 5, the crankshaft 5 of the present invention is connected with the piston 52 through the connecting rod 51, the bottom of the crankshaft 5 has a counterweight 53, and the two sides of the counterweight 53 are respectively sleeved with bearings 54 In addition, a driving gear 55 is arranged between the counterweight 53 and the bearing 54 on one side, and a balance shaft 6 is arranged beside the parallel side of the crankshaft 5 .

[0024] A balance gear 7 is sheathed on the sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com