Back light module unit and light conducting plate thereof

A technology of backlight module and light guide plate, applied in the direction of light guide, optics, optical components, etc., can solve the problem of difficulty in eliminating fireflies, and achieve the effect of eliminating firefly phenomenon and reducing energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

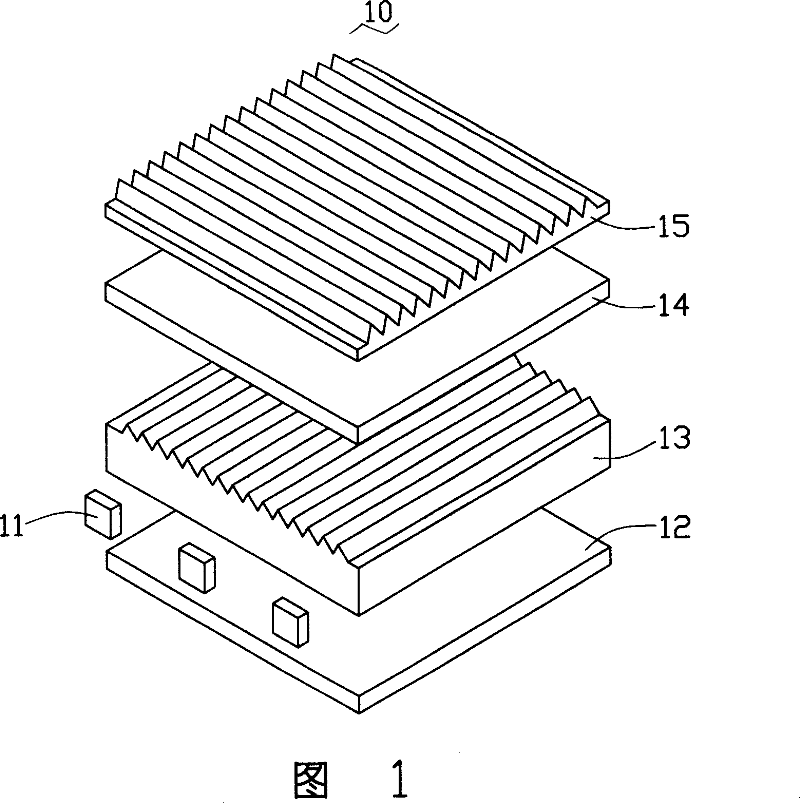

[0024] The backlight module and its light guide plate of the present invention will be further described in detail below with reference to the drawings and embodiments.

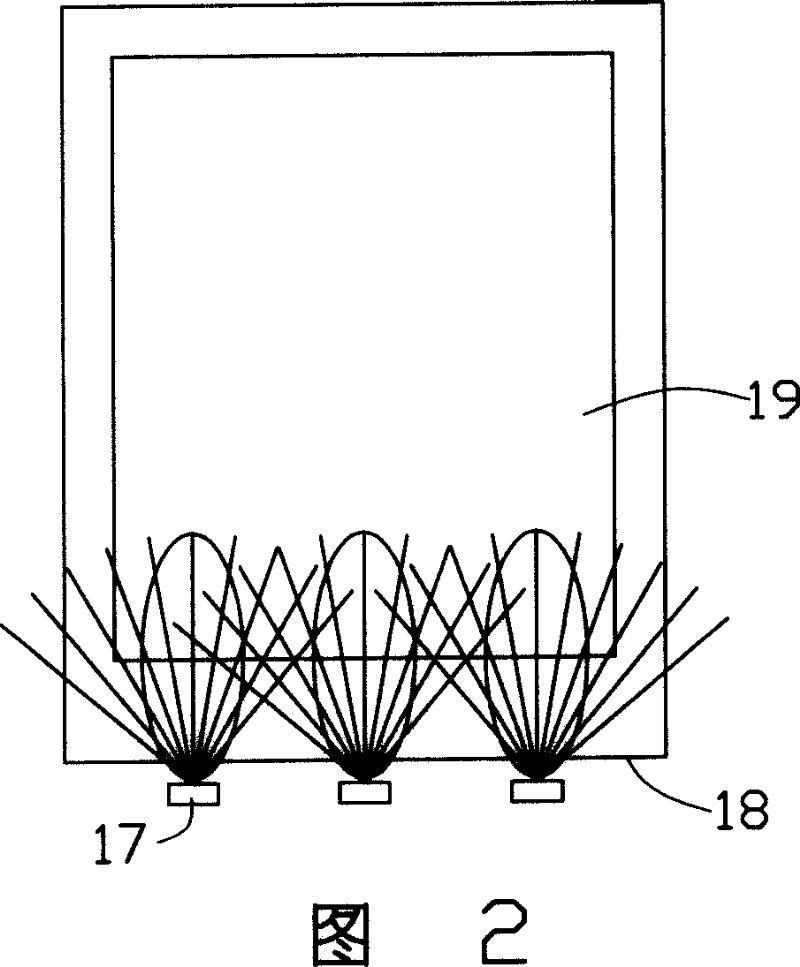

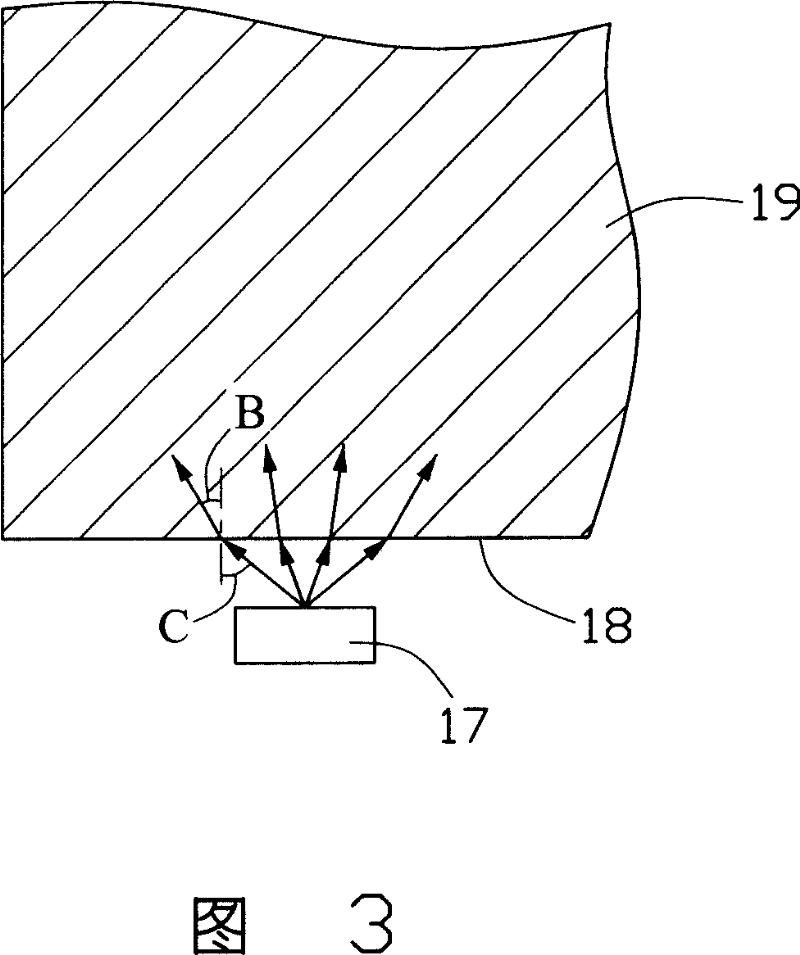

[0025] Please refer to FIG. 6 and FIG. 7 at the same time. The first embodiment of the present invention provides a backlight module 30 . The backlight module 30 includes a light guide plate 31 and a light source 33 located on one side of the light guide plate 31. The light source 33 is composed of a plurality of LED light sources. The light splitting groove 32 is a cylindrical hole with an arcuate cross section, and the light splitting groove 32 can be a through hole or a blind hole. When the light L emitted from the light source 33 passes through the incident surface 311, due to the refractive index n of the air 0 greater than the refractive index n of the light guide plate 31 1 , the first refraction will occur. The incident angle of light entering the light splitting groove 32 becomes B, and since the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com