Electro-thermal irradiation drying device

A drying device and electric heating technology, applied in the direction of heating device, drying, drying machine, etc., can solve the problems of poor material fixing effect, easy to be blown away, low drying efficiency, etc., to achieve drying and irradiation The effect of uniformity and expansion of the irradiation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

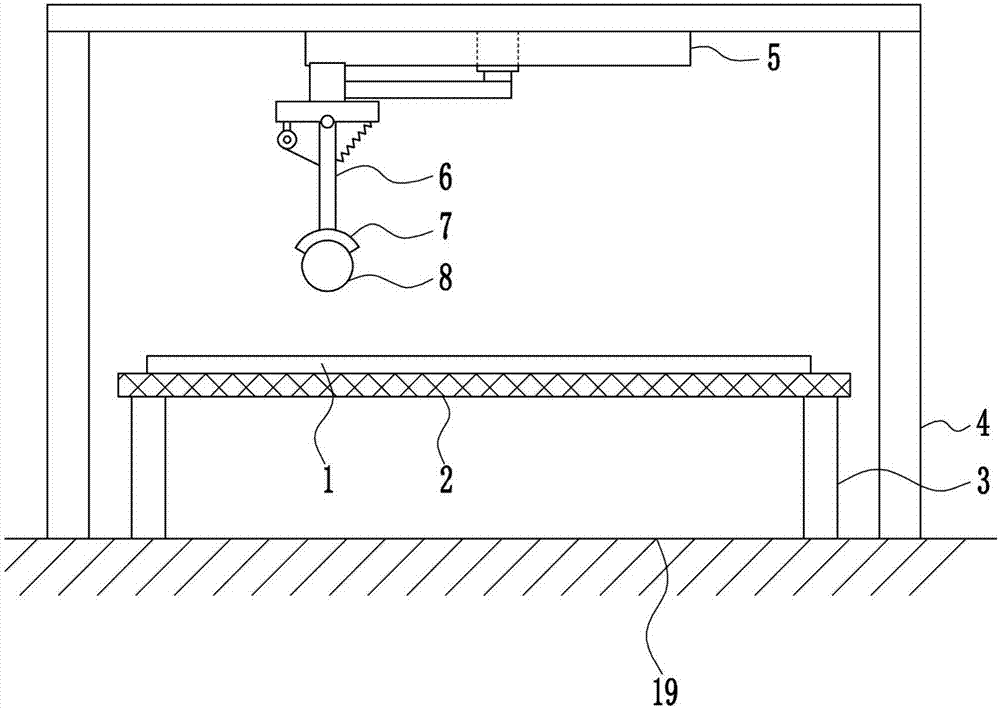

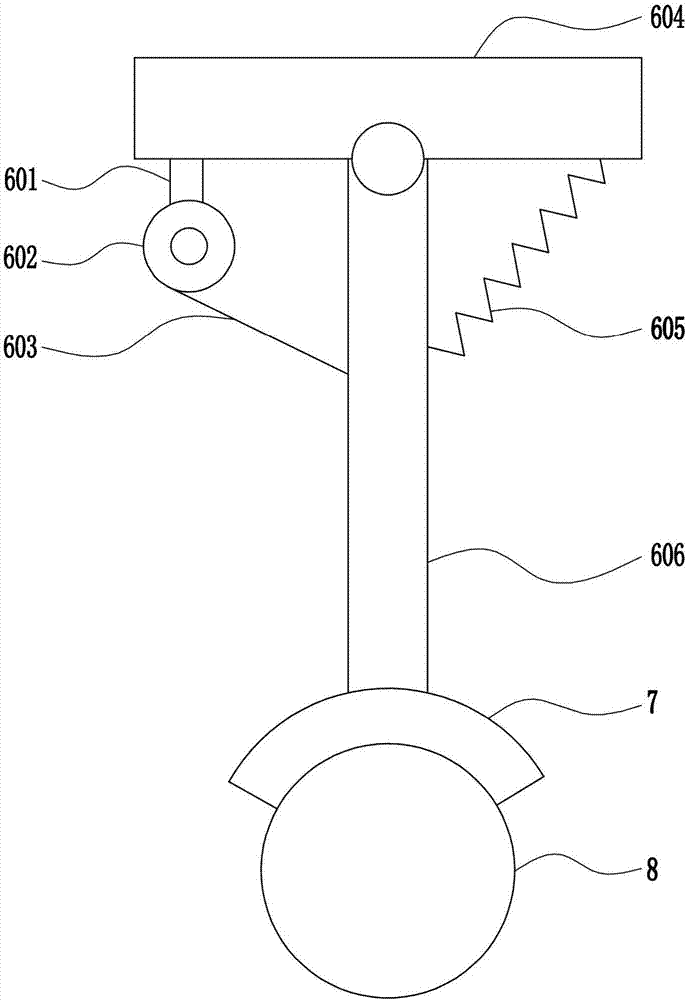

[0034] An electric heating irradiation drying device, such as Figure 1-5 As shown, it includes placing a grid plate 2, a first pole 3, a support 4, a rotating device 5, a swing device 6, a lampshade 7 and a warm light 8, and the ground 19 is provided with a first pole 3 and a support 4, and The first pole 3 is located inside the support 4, the top of the first pole 3 is provided with a grid plate 2, the top of the support 4 is provided with a rotating device 5, the bottom of the rotating device 5 is provided with a swing device 6, and the bottom of the swing device 6 is provided with a lampshade 7 , The bottom of the lampshade 7 is provided with a warm light 8, and the warm light 8 is located above the grid plate 2.

Embodiment 2

[0036] An electric heating irradiation drying device, such as Figure 1-5 As shown, it includes placing a grid plate 2, a first pole 3, a support 4, a rotating device 5, a swing device 6, a lampshade 7 and a warm light 8, and the ground 19 is provided with a first pole 3 and a support 4, and The first pole 3 is located inside the support 4, the top of the first pole 3 is provided with a grid plate 2, the top of the support 4 is provided with a rotating device 5, the bottom of the rotating device 5 is provided with a swing device 6, and the bottom of the swing device 6 is provided with a lampshade 7 , The bottom of the lampshade 7 is provided with a warm light 8, and the warm light 8 is located above the grid plate 2.

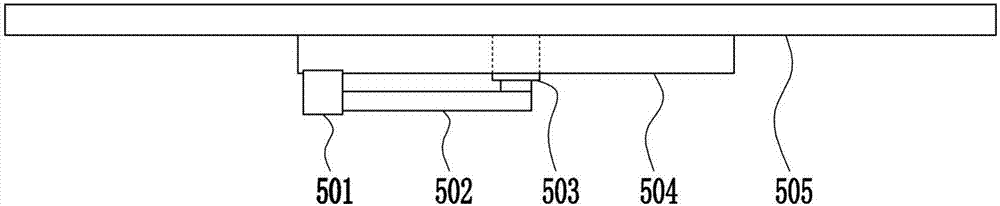

[0037]The rotating device 5 includes a first slider 501, a first connecting rod 502, a motor 503, an annular slide rail 504 and a top plate 505, the top of the support 4 is provided with a top plate 505, and the middle position of the bottom of the top plate 505...

Embodiment 3

[0039] An electric heating irradiation drying device, such as Figure 1-5 As shown, it includes placing a grid plate 2, a first pole 3, a support 4, a rotating device 5, a swing device 6, a lampshade 7 and a warm light 8, and the ground 19 is provided with a first pole 3 and a support 4, and The first pole 3 is located inside the support 4, the top of the first pole 3 is provided with a grid plate 2, the top of the support 4 is provided with a rotating device 5, the bottom of the rotating device 5 is provided with a swing device 6, and the bottom of the swing device 6 is provided with a lampshade 7 , The bottom of the lampshade 7 is provided with a warm light 8, and the warm light 8 is located above the grid plate 2.

[0040] The rotating device 5 includes a first slider 501, a first connecting rod 502, a motor 503, an annular slide rail 504 and a top plate 505, the top of the support 4 is provided with a top plate 505, and the middle position of the bottom of the top plate 50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com