Method and device for igniting and monitoring a burner

A burner and fuel technology, applied in the direction of burner ignition device, combustion method, gas fuel burner, etc., can solve the problems of flame symmetry interference and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

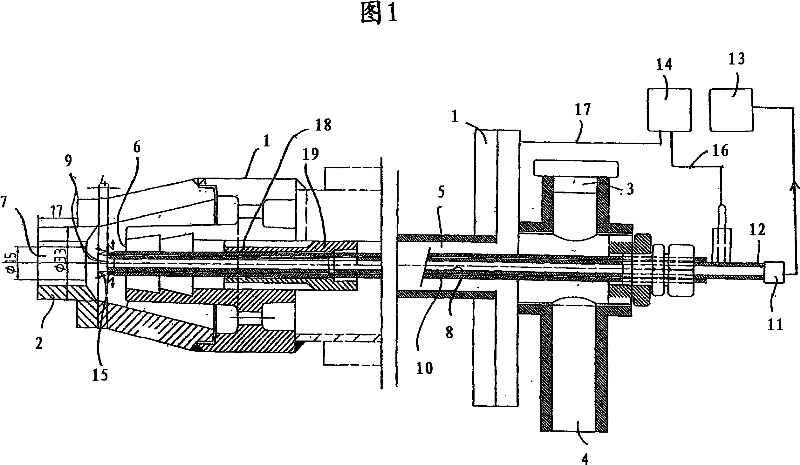

[0016] Figure 1 shows a high velocity burner designed to discharge a fuel / oxygen mixture from a burner head 2 at high velocity, where the length of the flame depends on said velocity. Figure 1 shows only the front and rear of the burner. The rear of the burner includes respective fuel and oxygen-containing gas inlets 3,4. This mixture is conveyed in a tubular channel 5 whose mouth 6 is surrounded by the burner head 2 . The burner head comprises a mixture outlet 7 and the mixture is burned outside the burner head.

[0017] According to the invention, the burner comprises a conductive tube 8 located inside and coaxially with the fuel mixture delivery channel 5 of the burner 1 . The first end 9 of the tube 8 terminates at the outlet of the fuel mixture close to the burner head.

[0018] Furthermore, the tube has an electrical insulator 10 which, according to a preferred embodiment of the invention, consists of a ceramic tube embedded in the conductive tube.

[0019] According...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com