Gas cell using two parabolic concave mirrors and method of producing gas sensor using the same

A parabolic and concave mirror technology, applied in instruments, scientific instruments, material analysis by optical means, etc., can solve a lot of problems such as time and high cost, and achieve the effect of reducing cost, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The structure of the present invention will be described below with reference to the drawings.

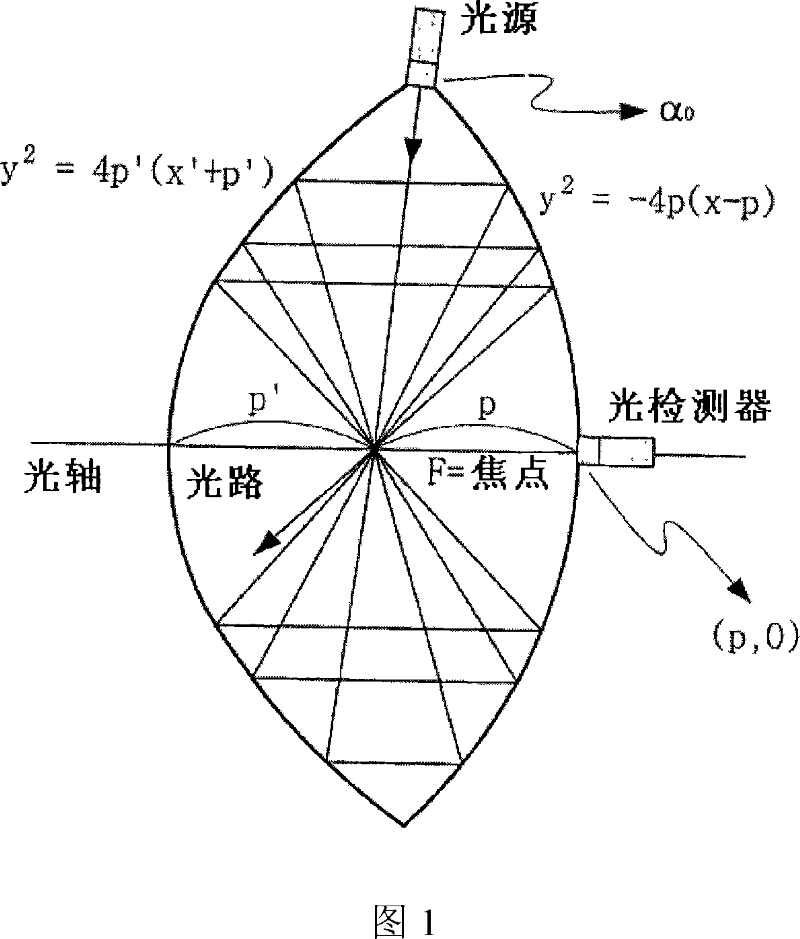

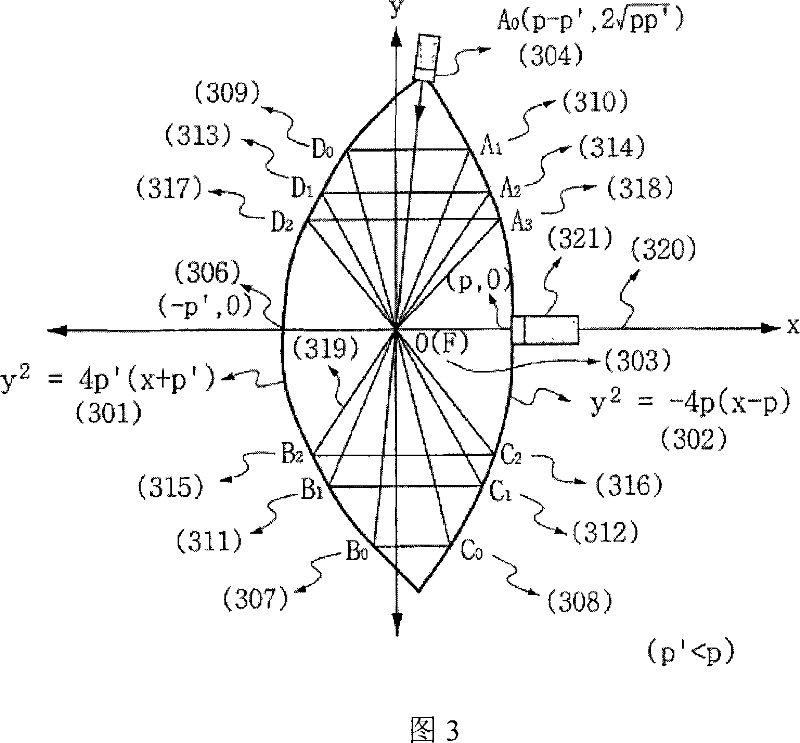

[0028] Figure 1 shows an optical cavity using two quadratic parabolic concave mirrors according to one embodiment of the present invention.

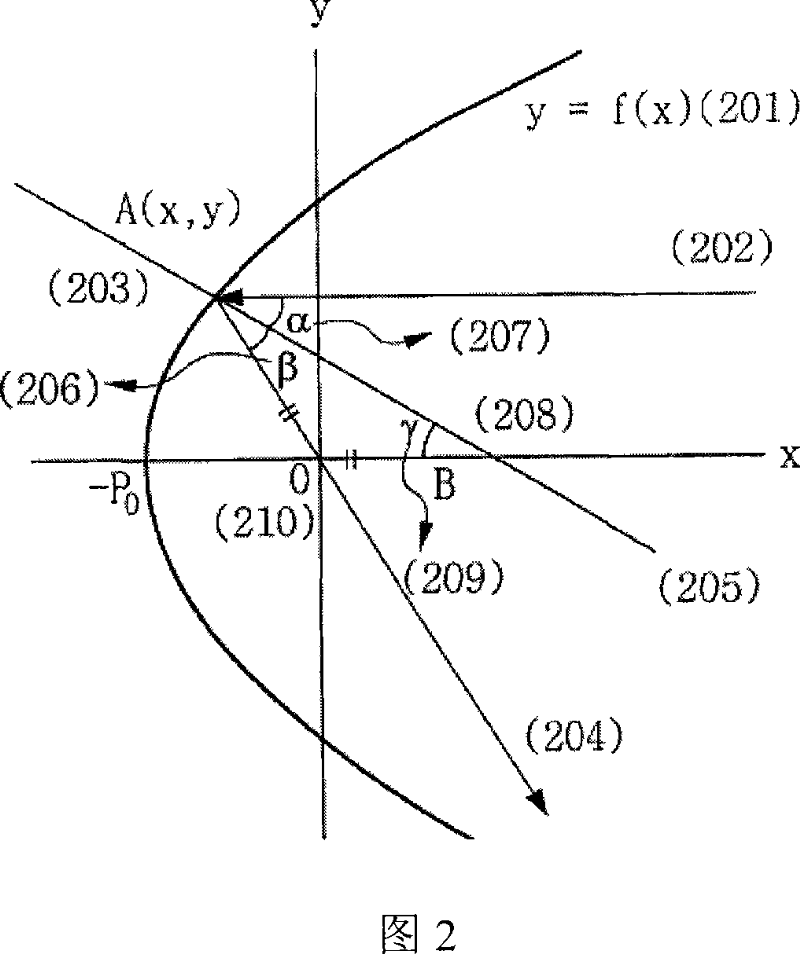

[0029] In a parabolic concave mirror, light incident toward the focal point travels parallel to the optical axis after being reflected by the mirror, and light incident parallel to the optical axis passes through the focus after being reflected by the mirror. Based on the above reflection characteristics of parabolic concave mirrors, as shown in Figure 1, two concave mirrors are arranged opposite to each other, so that the two concave mirrors obtained from two quadratic functions with focal lengths p and p′ are confocal, thereby forming a light cavity. At this point, the light source is at position A 0 And towards the focal point, the photodetector is located at the optical axis (p,0) along the -x direction.

[0030] The light emitt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com