Forward-reverse switching device for stepless speed changer

A technology of forward and backward, switching devices, applied in the direction of transmission, transmission parts, transmission control, etc., can solve the problems of large friction loss, unoptimized torque transmission, complicated hydraulic control, etc., to reduce processing costs, reduce Small friction loss, simple hydraulic control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0054] Example 1

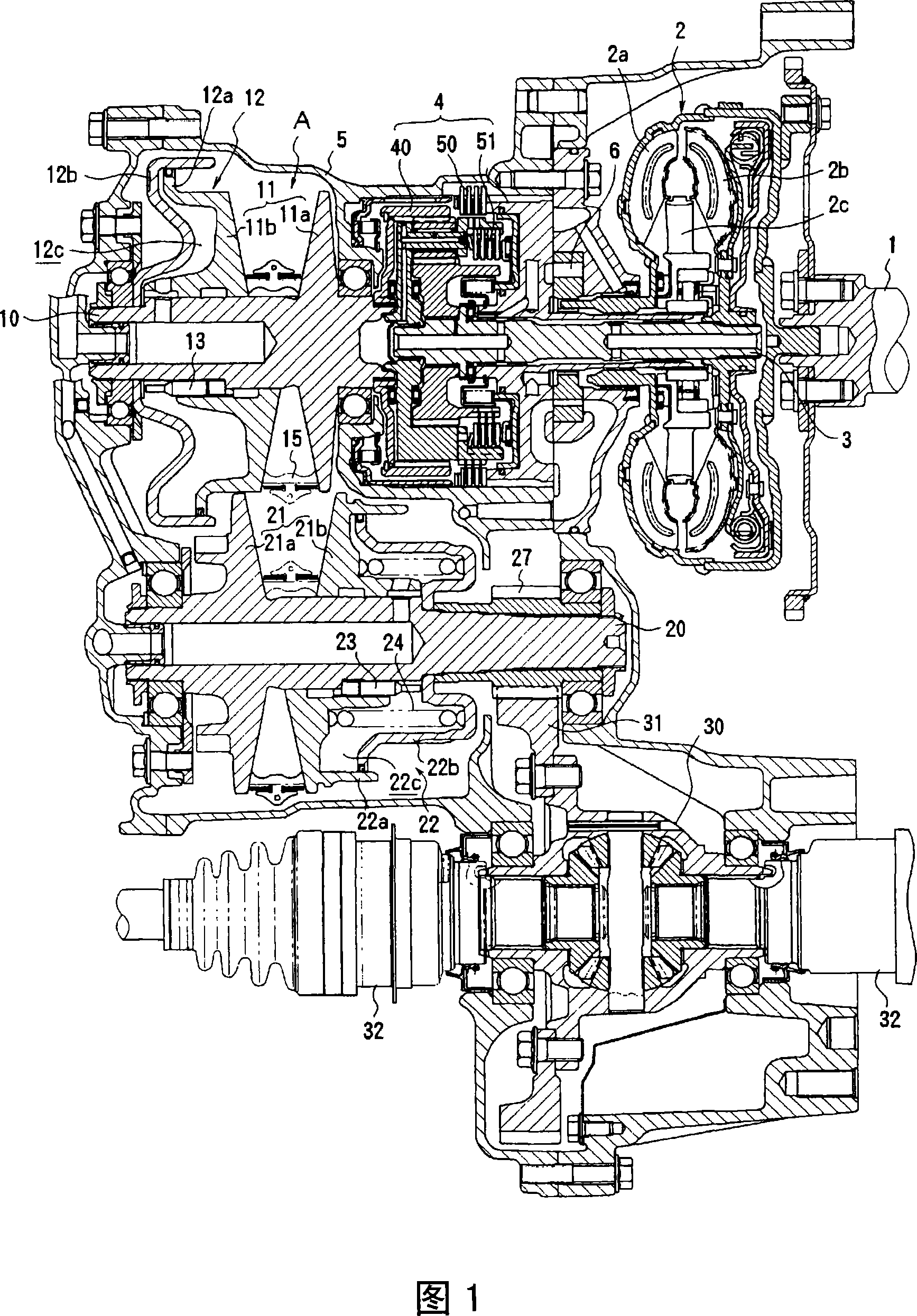

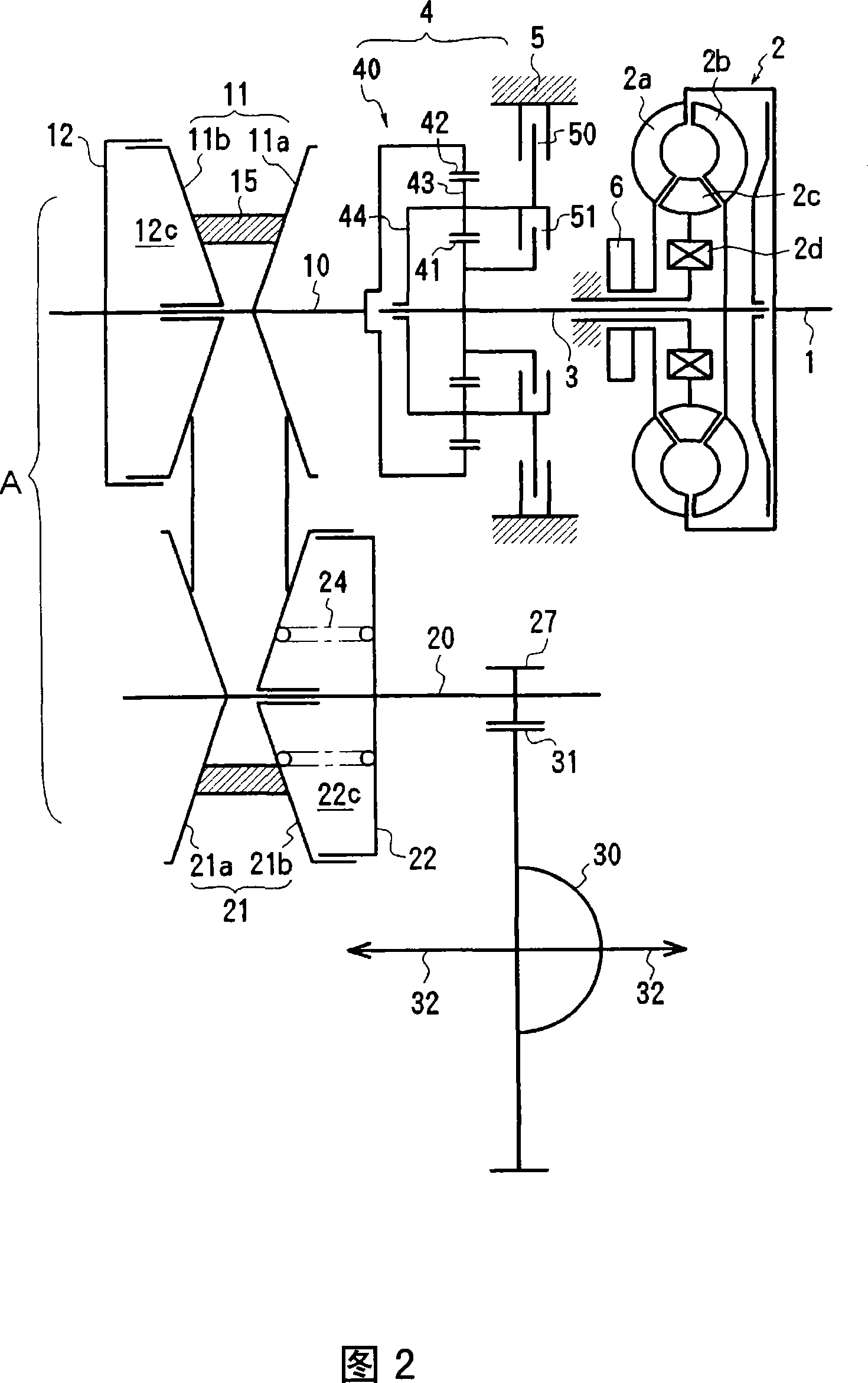

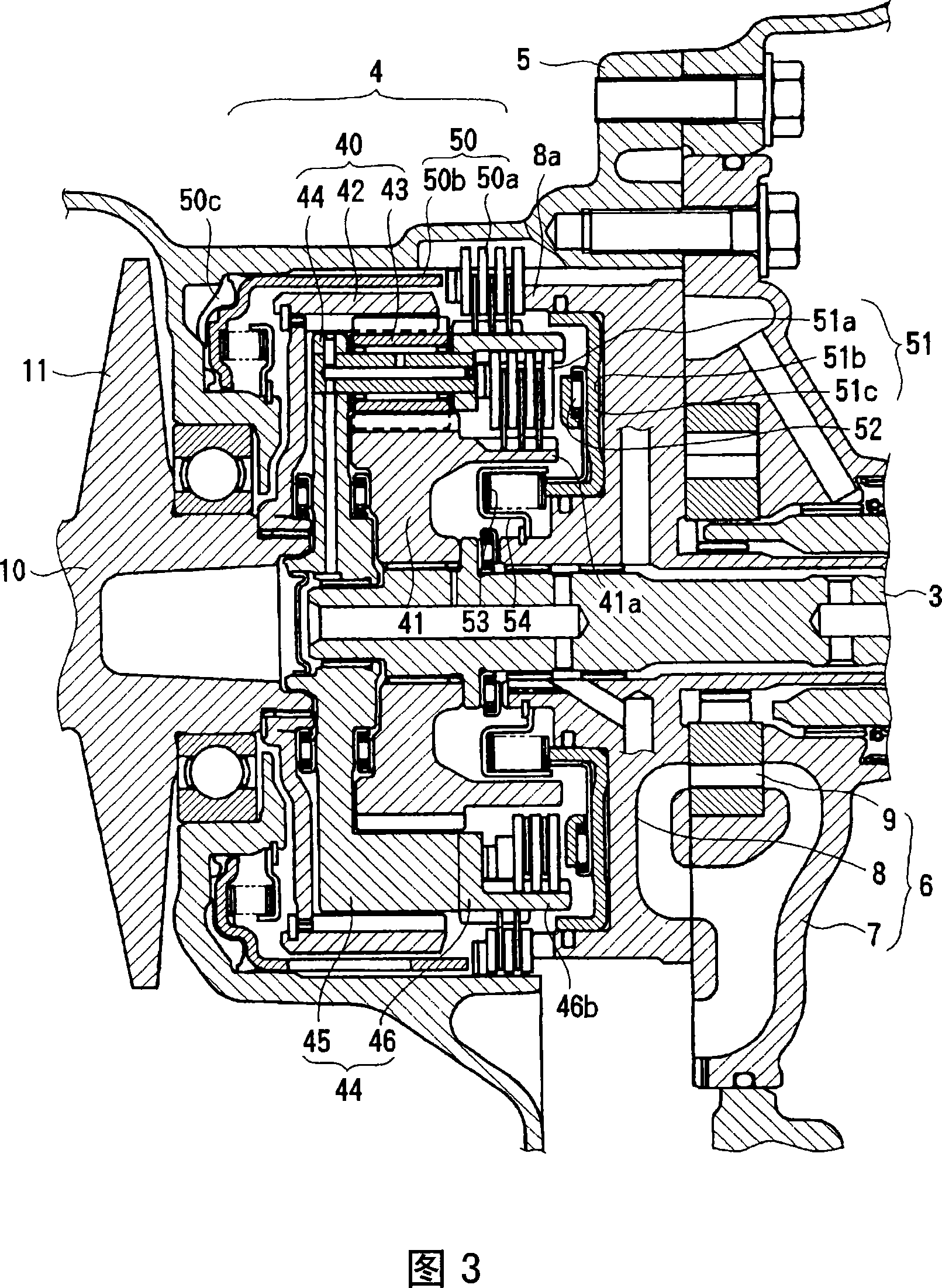

[0055] Figures 1 to 3 show an example of the continuously variable transmission of the present invention.

[0056] The continuously variable transmission of this embodiment is an FF horizontal type automobile transmission, and roughly includes: an input shaft 3 driven by a torque converter 2 under the action of an engine output shaft 1; The forward and backward switching device 4 transmitted to the drive shaft 10; the continuously variable transmission device A composed of the drive wheel 11, the driven wheel 21, and the V belt 15 wound between the two wheels; the power of the driven shaft 20 is directed to the output shaft 32 transfer of the differential device 30 and so on. The input shaft 3 and the drive shaft 10 are arranged on the same axis, and the driven shaft 20 and the output shaft 32 of the differential device 30 are arranged in parallel and non-coaxially with respect to the input shaft 3. Therefore, the continuously variable transmission is formed as ...

Example Embodiment

[0079] Example 2

[0080] Fig. 7 shows a second embodiment of the forward and backward switching device of the present invention. In FIG. 7, the same parts as those in the first embodiment are denoted by the same symbols, and repeated descriptions are omitted. In addition, the structure other than the forward-reverse switching device is the same as in Patent Document 2.

[0081] The planetary gear mechanism 40' is formed in a double pinion system, and the planetary carrier 44 supports two types of pinion gears 43A and 43B. One pinion gear 43A meshes with the ring gear 42 and the pinion gear 43B, and the other pinion gear 43B meshes with the pinion gear 43A and the sun gear 41. The sun gear 41 is combined with the input shaft 3, and the planetary gear carrier 44 is combined with the drive shaft 10. The reverse brake 50 is provided between the ring gear 42 and the transmission housing 5, and the hydraulic piston 50 b for operating the reverse brake 50 is arranged in the transmission...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap