Seesaw type squat toilet frame base

A squatting pan and seesaw technology, which is applied to flushing equipment with water tanks, flushing toilets, water supply devices, etc., can solve the problems of high cost, difficult maintenance, and unsuitable for high-frequency use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

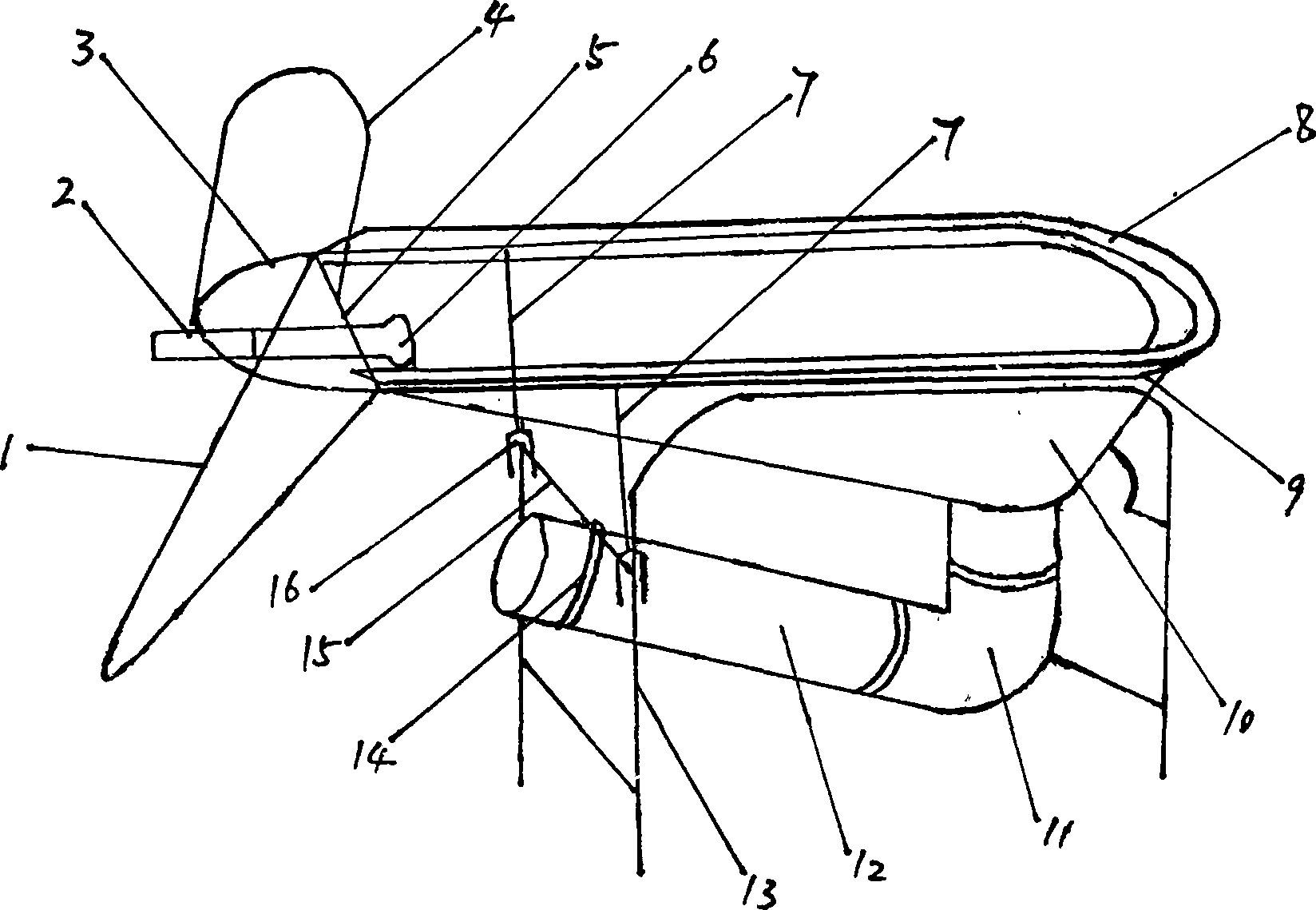

[0007] With reference to accompanying drawing, seesaw type squatting pan bucket frame 3,9 of the present invention is divided into middle, upper and lower three parts, and described middle part 3,9 is preferably 10 millimeters in diameter, is long and is 156mm. The steel bar of centimeter is an elliptical circle 3,9 that forms with the circumference of the whole barrel edge 8 of the squatting pan barrel as a standard, and the two ends are semicircular; the length from the front end to the rear end of the oval circle 3,9 is 60 cm, the diameter of the front semicircular circle 3 is 18 centimeters, and the diameter of the rear semicircular circle 9 is 20 centimeters; at the front end of the oval frame, the diameter of the semicircular circle 3 is 10 millimeters, a section of steel bar with a length of 18 centimeters 5. Fix the two ends of the semicircular circle 3 together to form a beam 5, weld and fix a section of water inlet pipe with a diameter of 21 mm and a length of 8 cm un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com