Drawing rivet guns

A technology of pulling riveting gun and inner collar, applied in the field of pulling riveting gun, can solve the problems of weak connection, stress concentration, broken piston 14, etc., so as to prolong the overall trouble-free working time, improve the trouble-free working time, and save maintenance. effect of funding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

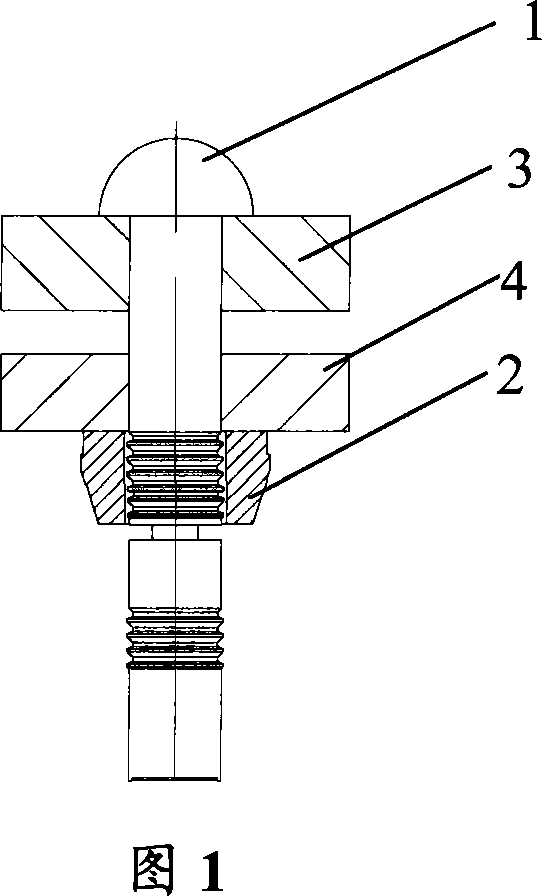

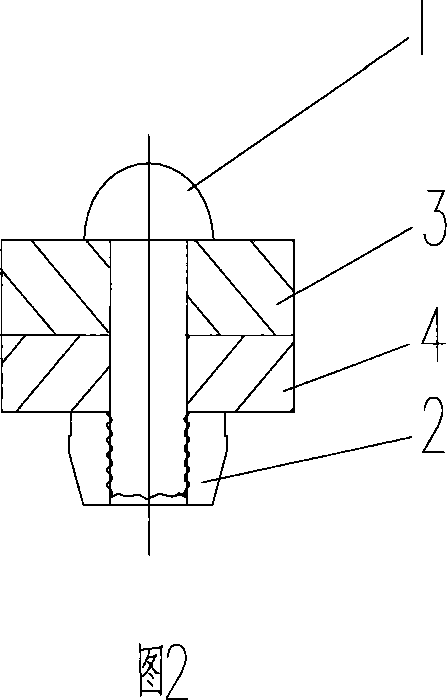

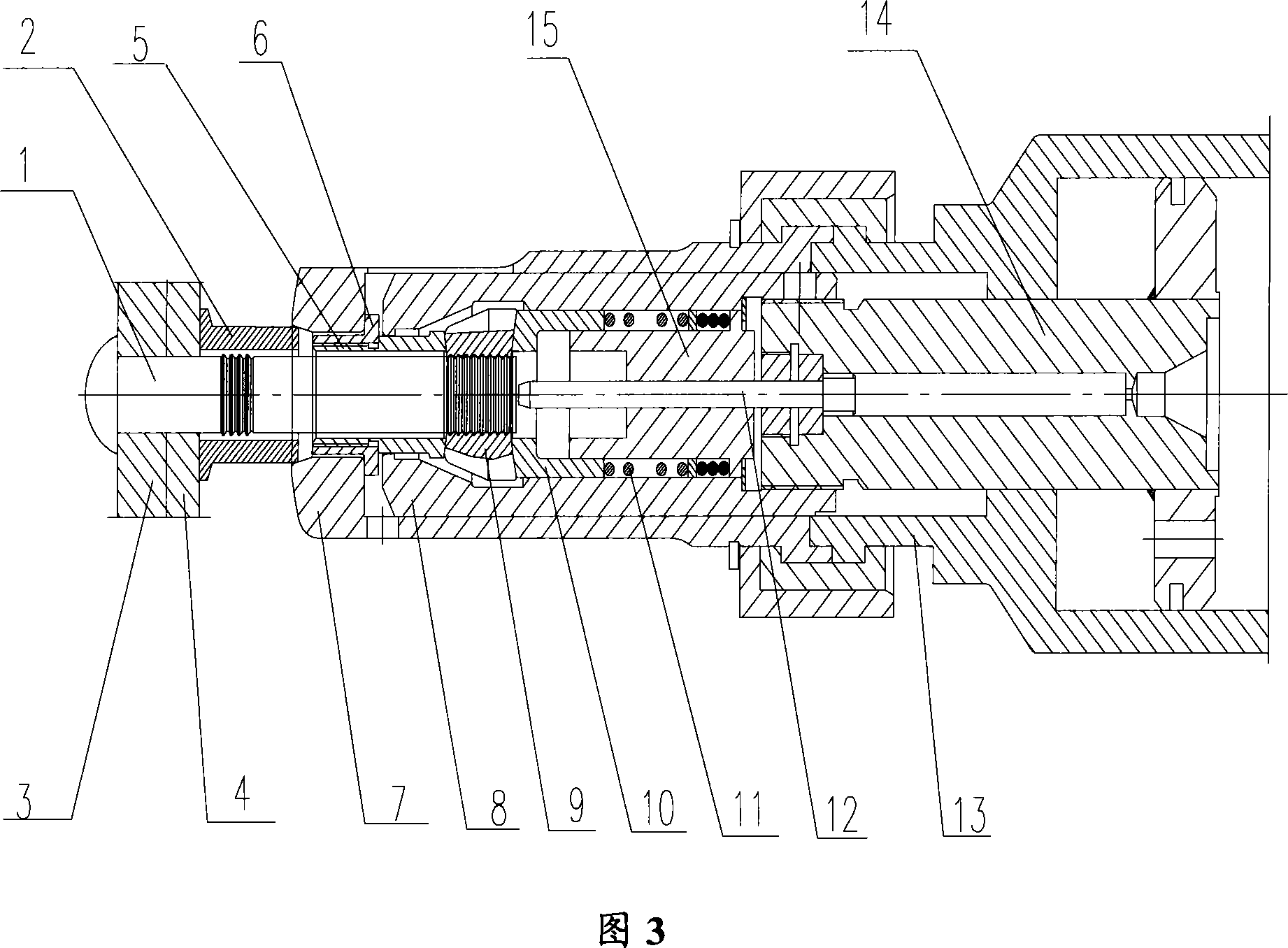

[0043] Please refer to FIG. 7 , which is a structural diagram of the riveting gun provided by the first embodiment of the present invention.

[0044] As shown in the figure, the basic structure of the riveting gun is basically the same as that of the riveting gun described in the background art, so the working principle of the riveting gun will not be introduced here, and only the improved part will be introduced.

[0045] In Fig. 7, the abdication group at the front end of the riveting gun has been improved. In order to clearly illustrate its improved parts, please refer to Fig. 8, which shows the structure of the abdication group of the riveting gun provided by the present invention.

[0046] Figure 8 shows that the abdication group also includes the abdication group inner collar 5' and the abdication group outer collar 6', because its structure is different from the prior art, therefore, different labels are used to show the difference (hereinafter referred to as the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com