Low-floor railroad (light rail) car for U-shape structure frame

A low-floor and frame technology, applied to suspensions, axles, wheels, etc., can solve the problem of inconvenience in getting on and off, and achieve the effect of scientific conception, simple process and easy manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

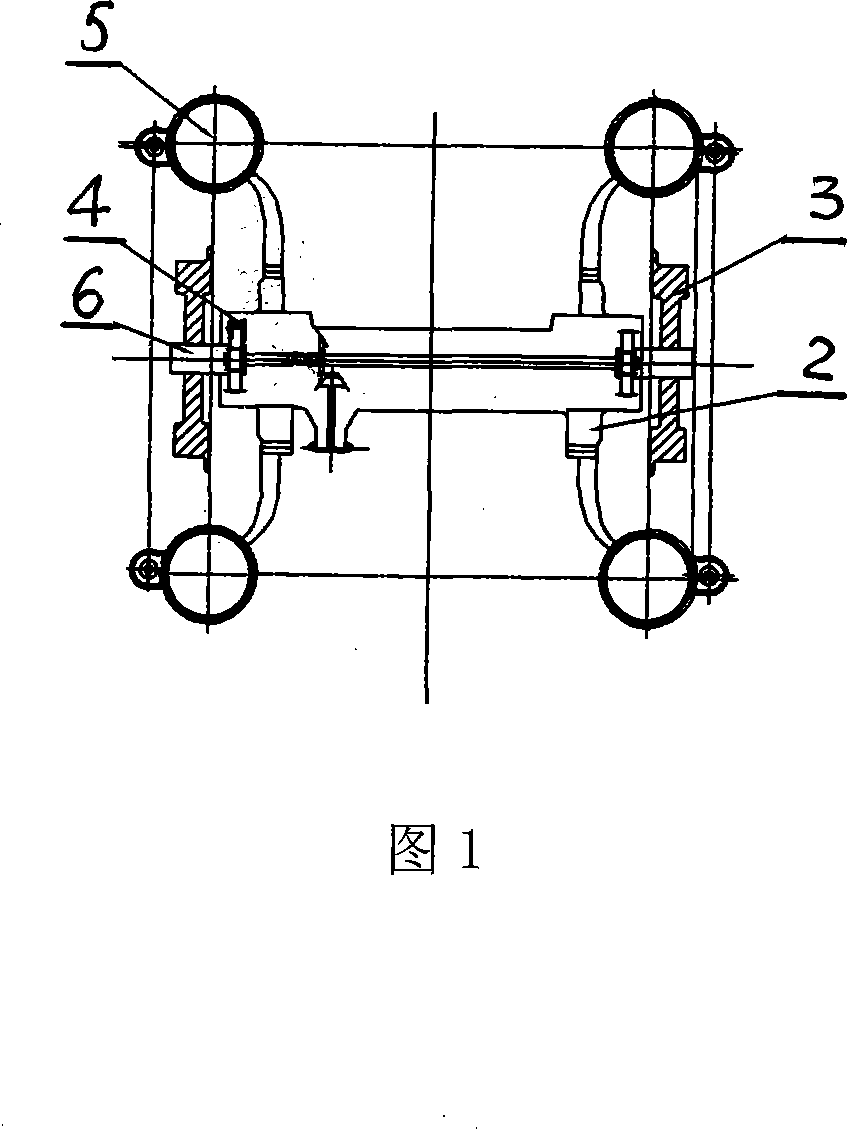

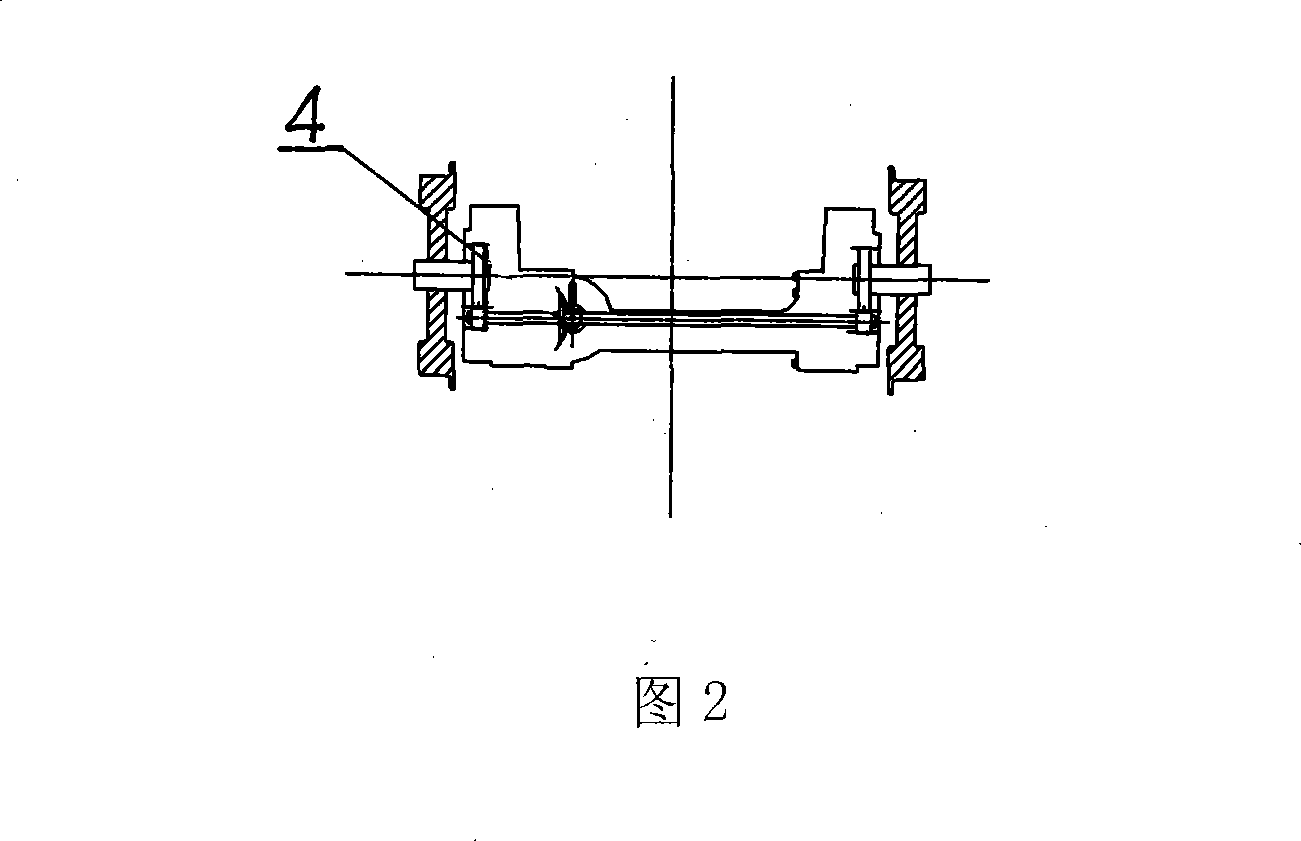

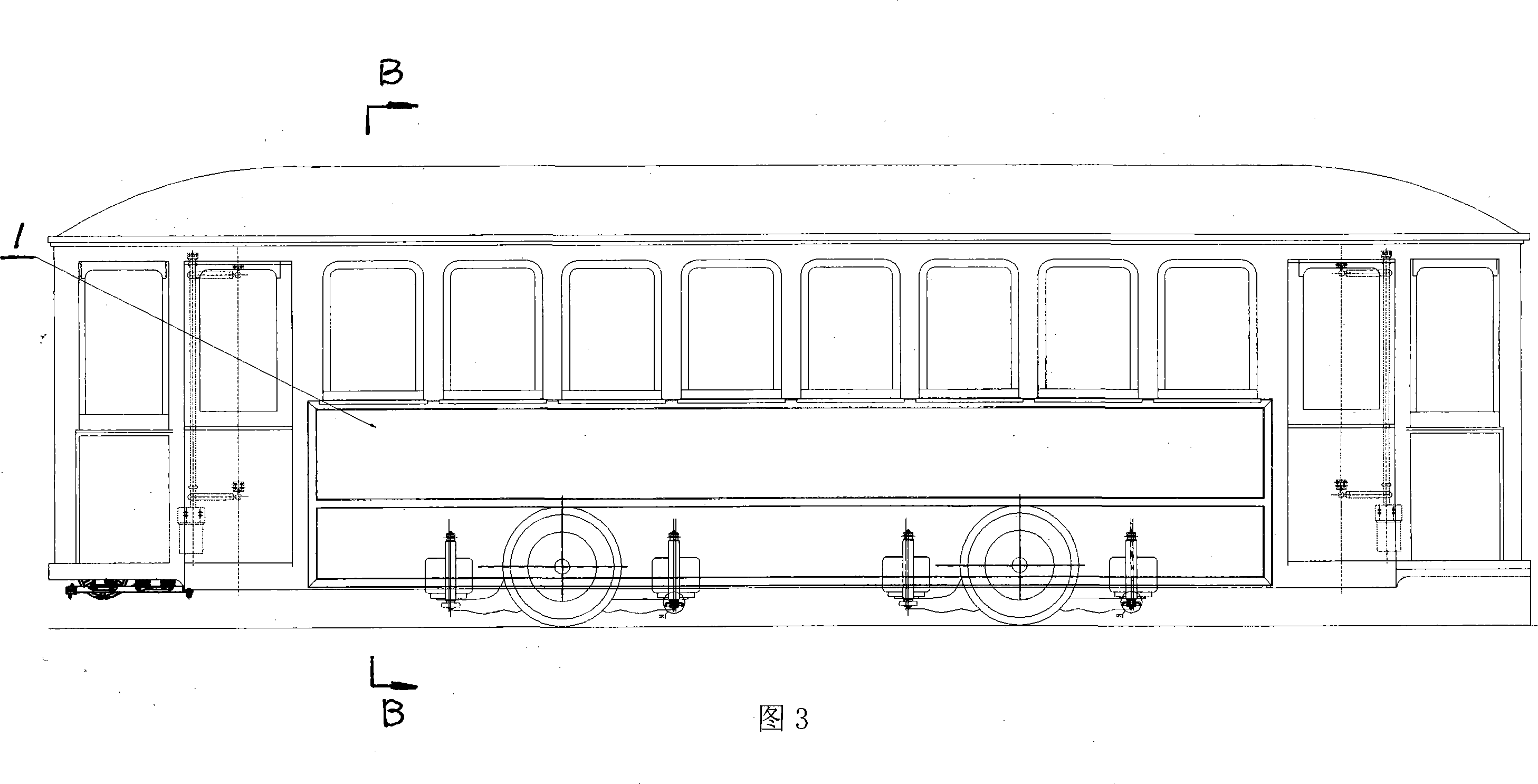

[0012] With reference to accompanying drawing, whole device is made up of car body 1, U-shaped vehicle frame 2, air spring 5, and air spring 5 is installed on U-shaped vehicle frame 2, and car body 1 is installed on the air spring 5. U-shaped vehicle frame 2 comprises wheel 3, transmission gear 4, axle shaft 6, and wheel 3 is connected with transmission gear 4 and makes vehicle frame be U-shaped, and the power of vehicle running is transmitted on the wheel 3 by the transmission gear 4 that is installed in wheel limit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com