Powder injection argon blowing pressure casting technology

A casting process and powder injection technology, applied in the field of die casting, to achieve the effect of fine grain, flexible operation and scientific conception

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

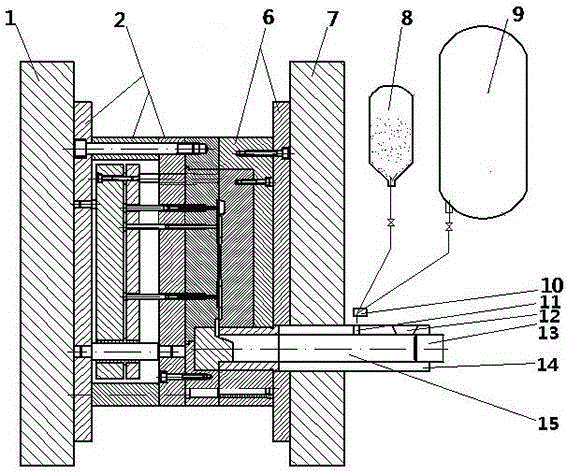

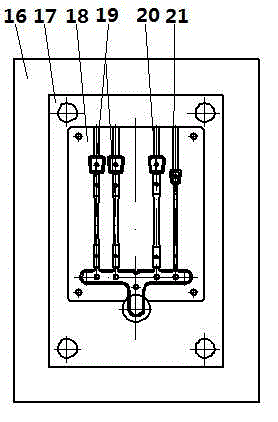

[0025] A powder injection and argon blowing die-casting process system is realized on a sample die-casting mold. figure 2 It is a top view of the moving mold direction after the die-casting mold is opened. The die-casting mold is matched with a 350-ton die-casting machine. One mold has four cavities. It is designed according to the national standard "Die-casting non-ferrous alloy samples (GB / T 13822-1992)". Two tensile A samples and one tensile B sample are die-cast at one time. , an impact toughness sample, so there are four cavities in a pair of die-casting molds, namely, two tensile sample A cavity 19, one tensile sample B cavity 20, and one impact toughness sample cavity twenty one. Among them, the mold material is H13 steel; it can be seen from the figure that the die-casting mold is basically the same as the ordinary high-pressure die-casting mold, so there is no need to make any changes to the mold during the powder injection and argon blowing process. The powder inj...

Embodiment 2

[0027] For aluminum alloy die-casting parts with a pouring weight of 1500 grams, such as 90cc and 100cc motorcycle engine crankcase molds, it is matched with a 650-ton die-casting machine, with one mold and one cavity. The mold material is H13 steel. The powder injection and argon blowing process can be like this Setting: The injection punch 13 advances under the action of the injection mechanism of the die-casting machine, gradually blocks the pouring port 12, and injects argon gas into the injection chamber 15 for 0.3 seconds. At this time, the air in the injection chamber 15 is driven out. Go, the injection punch 13 has not reached the powder injection argon blowing channel 11; then the powder in the powder storage cylinder 8 passes through the powder storage cylinder 8, the powder injection argon blowing channel 11, and the powder injection argon blowing controller 10 into the injection chamber 15 Within 0.2 seconds, the injection stops, and argon gas is introduced at the s...

Embodiment 3

[0029]For aluminum alloy die-casting parts with a pouring weight of 3000 grams, such as a crankcase mold for a small car engine, it is matched with a 1500-ton die-casting machine, with one mold and one cavity, and the mold material is H13 steel. The powder injection and argon blowing process can be set as follows: The injection punch 13 advances under the action of the injection mechanism of the die-casting machine, gradually blocks the pouring port 12, and injects argon gas into the injection chamber 15 for 0.5 seconds. At this time, the air in the injection chamber 15 is driven away, and the pressure The injection punch 13 does not reach the powder injection argon blowing channel 11; then the powder in the powder storage cylinder 8 passes through the powder storage cylinder 8, the powder injection argon blowing channel 11, and the powder injection argon blowing controller 10 into the injection chamber 15, and injects Stop after 0.3 seconds, and feed argon gas at the same time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com