Rear axle reverse gear mechanism for four-wheel motorcycle

A technology for motorcycles and rear axles, applied to vehicle parts, control devices, transportation and packaging, etc., can solve the problems of power transmission stability, complex rear axle structure, large installation space, etc., to ensure stability and reliability , Unified movement coordination, and the effect of enhancing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

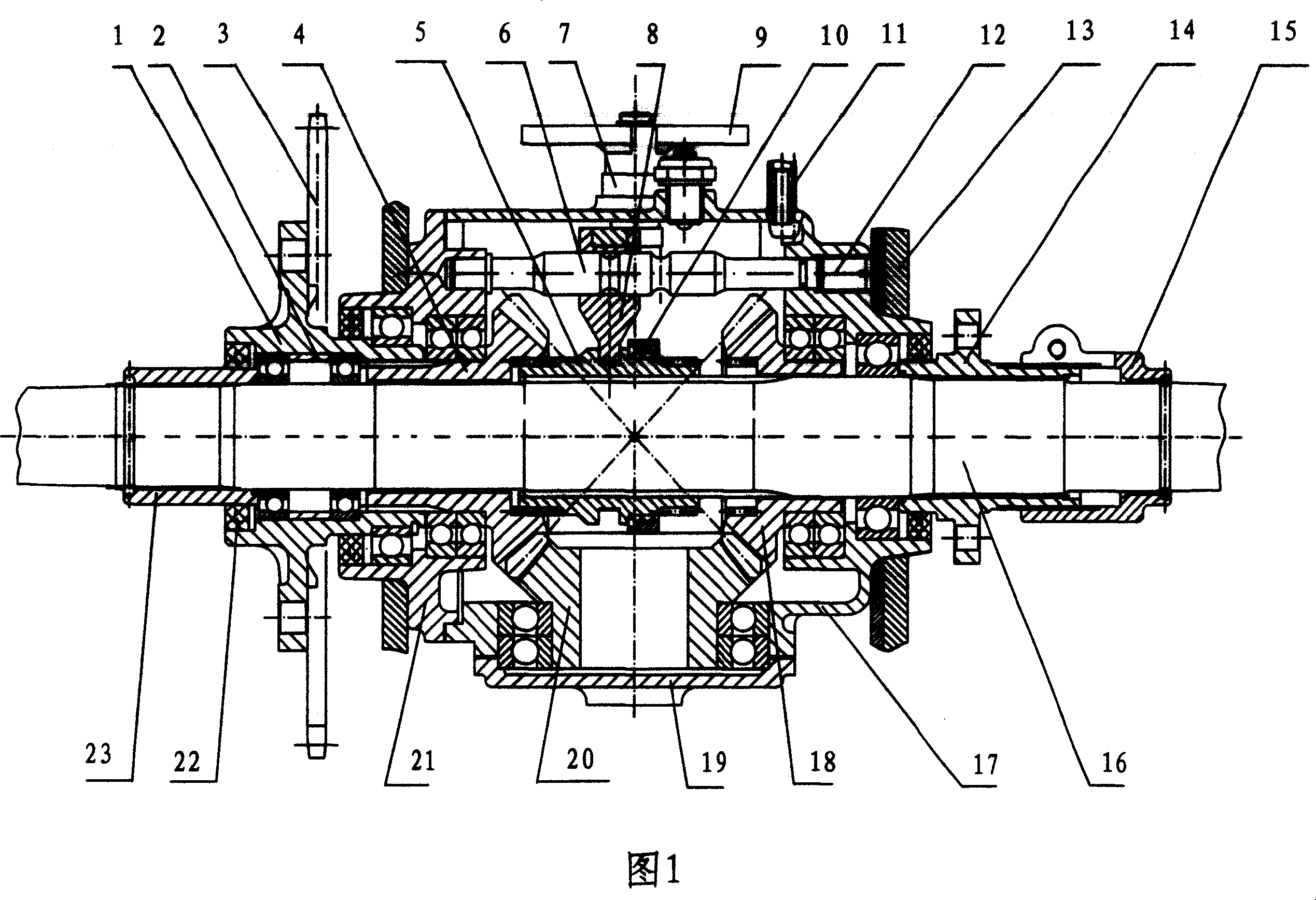

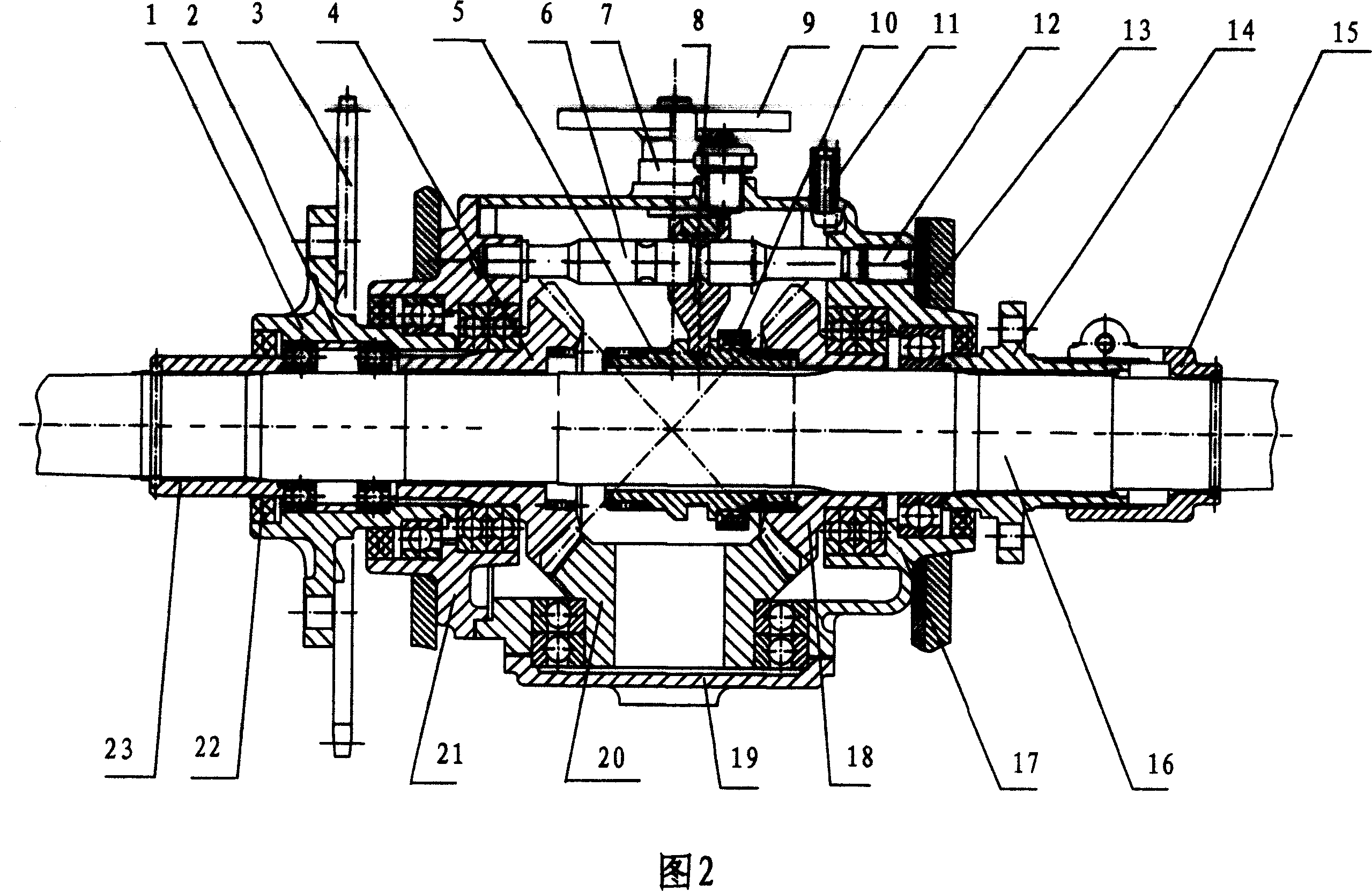

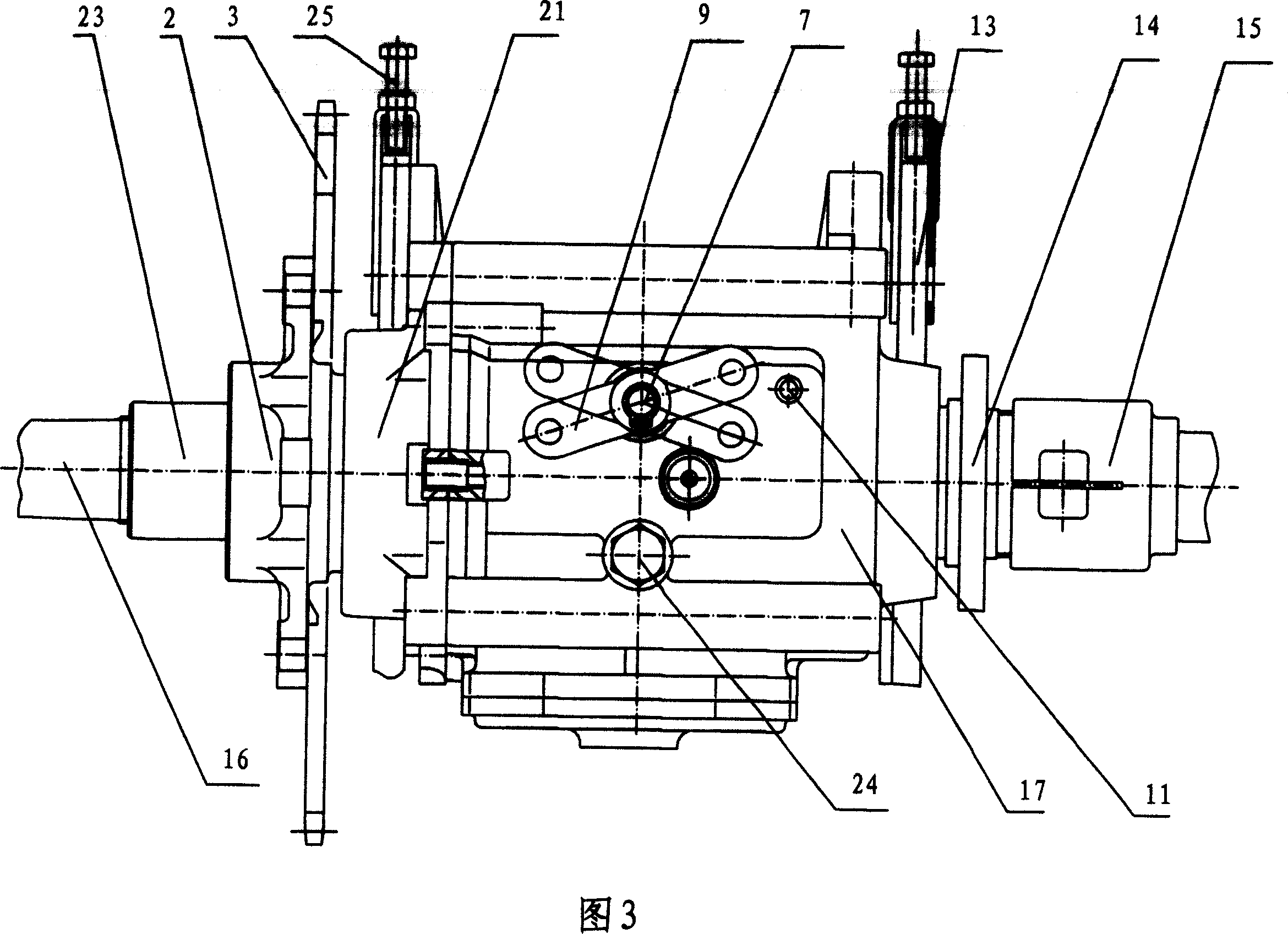

[0015]Referring to Fig. 1 to Fig. 3, a rear axle reverse gear mechanism of a four-wheel motorcycle commonly known as a beach car, the housing of the reverse gear mechanism is connected by a left housing 21, a right housing 17 and a lower cover 19 through a plurality of bolts Fixed structure, the shell is made of aluminum alloy die-casting, which realizes lightness. A rear axle 16 as the rear axle of the motorcycle runs through the housing from the shaft holes at the left and right ends of the housing, and the two ends of the rear axle 16 are respectively equipped with the left and right rear wheels of the motorcycle. The shaft holes at the left and right ends of the housing are respectively positioned and assembled with the driving bevel gear 4 and the driven bevel gear 18 through bearings. The idler bevel gear 20 meshes through the bearing. The shaft holes at the left and right ends of the housing are stepped holes, and the bearings on the driving bevel gear 4 and the driven...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap