Hot-melt glass substrate marble fountain production process

A production process, marble technology, applied in the direction of building locks, buildings, building structures, etc., to achieve the effect of flexible changes, high production efficiency, and elegant appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

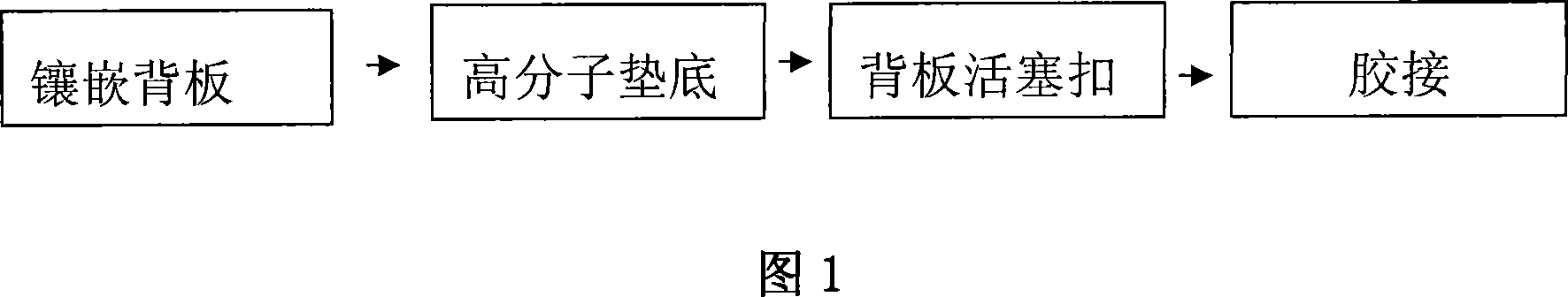

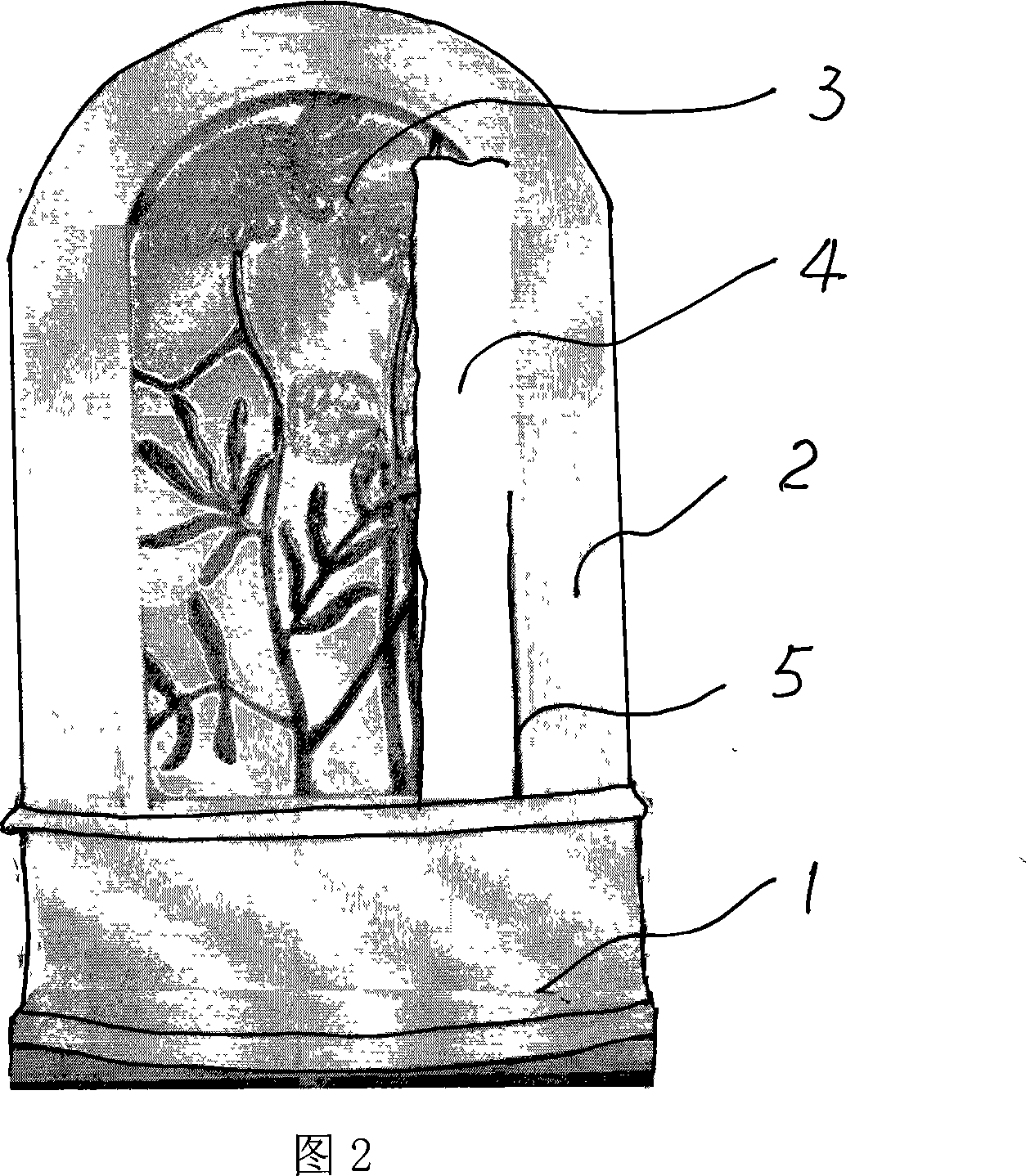

[0017] As shown in the process flow chart of the embodiment in Figure 1 and the structural schematic diagram of the marble fountain with a hot-melt glass substrate in Figure 2, a marble fountain with a hot-melt glass substrate is composed of a marble base 1 and a marble frame 2 as an annular frame, and a hot-melt glass 3 is embedded In the marble frame 2, its manufacturing process comprises the steps:

[0018] The first step: inlay the back plate 4 on the circular marble frame;

[0019] The second step: make the bottom material layer 5 with polymer material, and arrange it at the junction of the hot-melt glass and the circular marble plate, so as to protect and fix the hot-melt glass;

[0020] Step 3: Install detachable hooks (not shown in the figure) on the inner side of the back panel to fix hot-melt glass and other structures that need to be hung. The fixing method is to drill holes on the back panel and bury the steel components into the back panel to make a detachable ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com