Non symmetrical interleaving mixed exciting synchronization motor

A hybrid excitation synchronous and asymmetric technology, applied in the field of hybrid excitation synchronous motors and improved motors, can solve the problems of limited installation space of the excitation winding, increase the axial length of the motor, and reduce the utilization rate of materials, and achieves obvious magnetic adjustment effect. The effect of improving electric excitation efficiency and avoiding irreversible demagnetization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

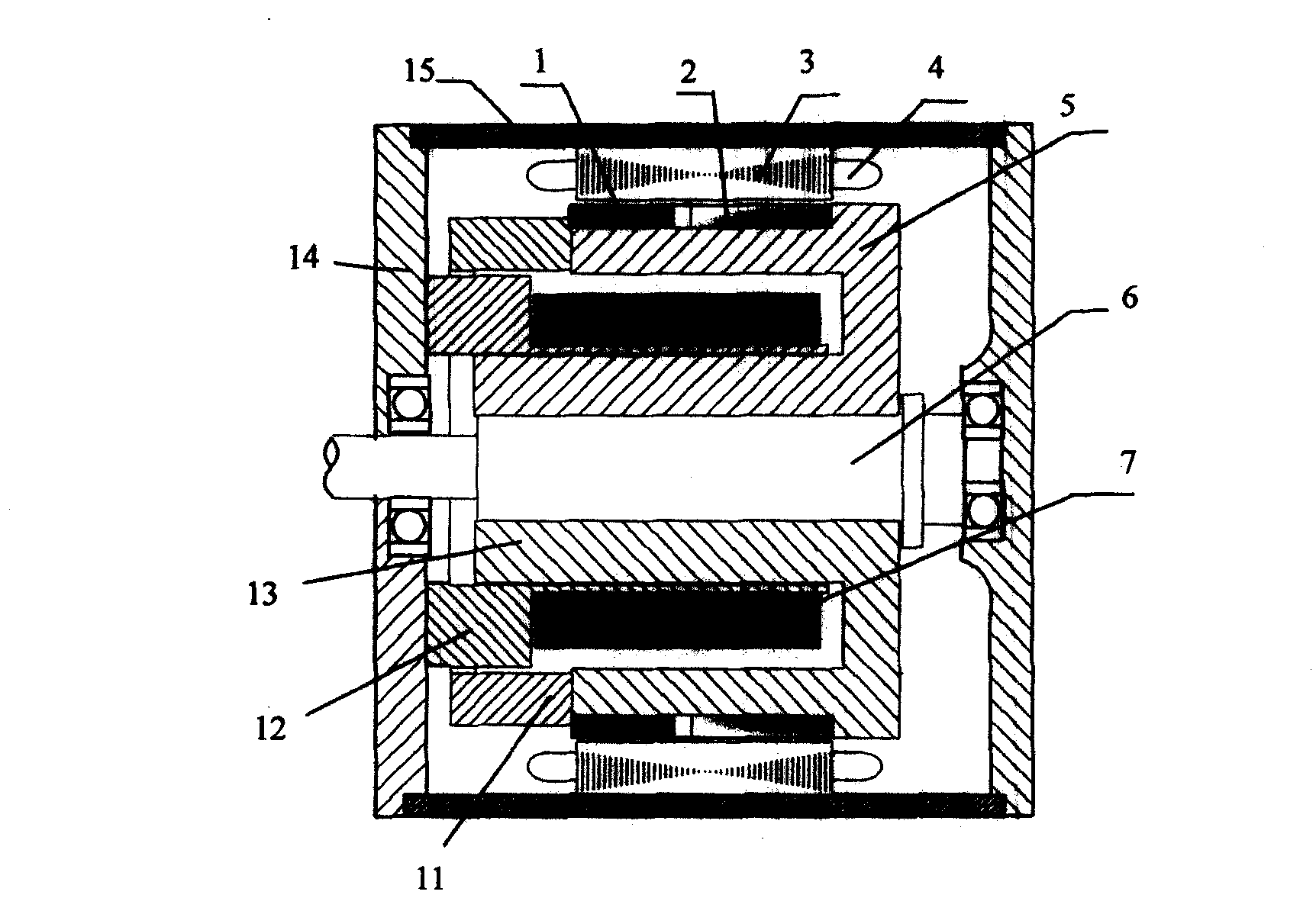

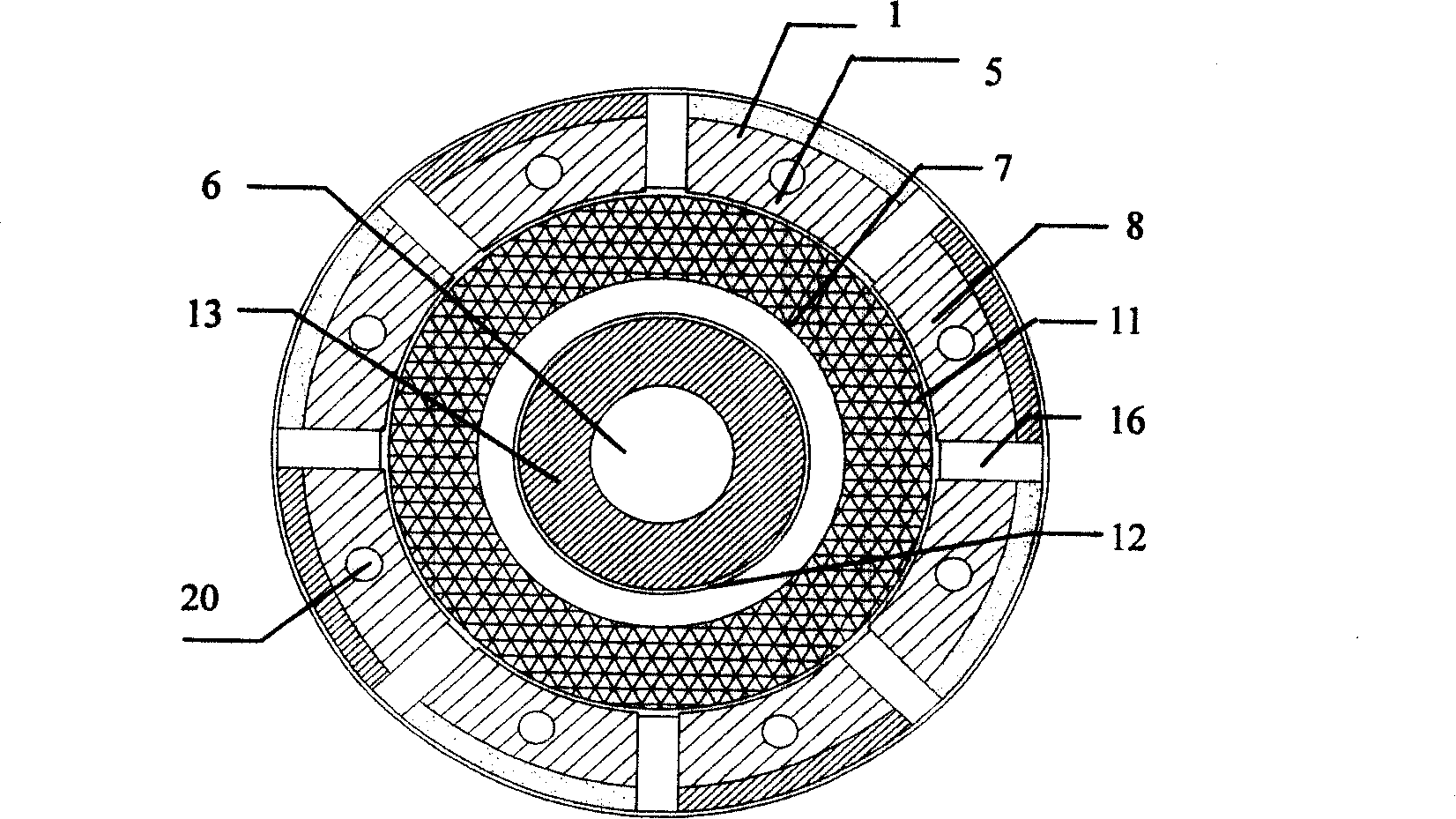

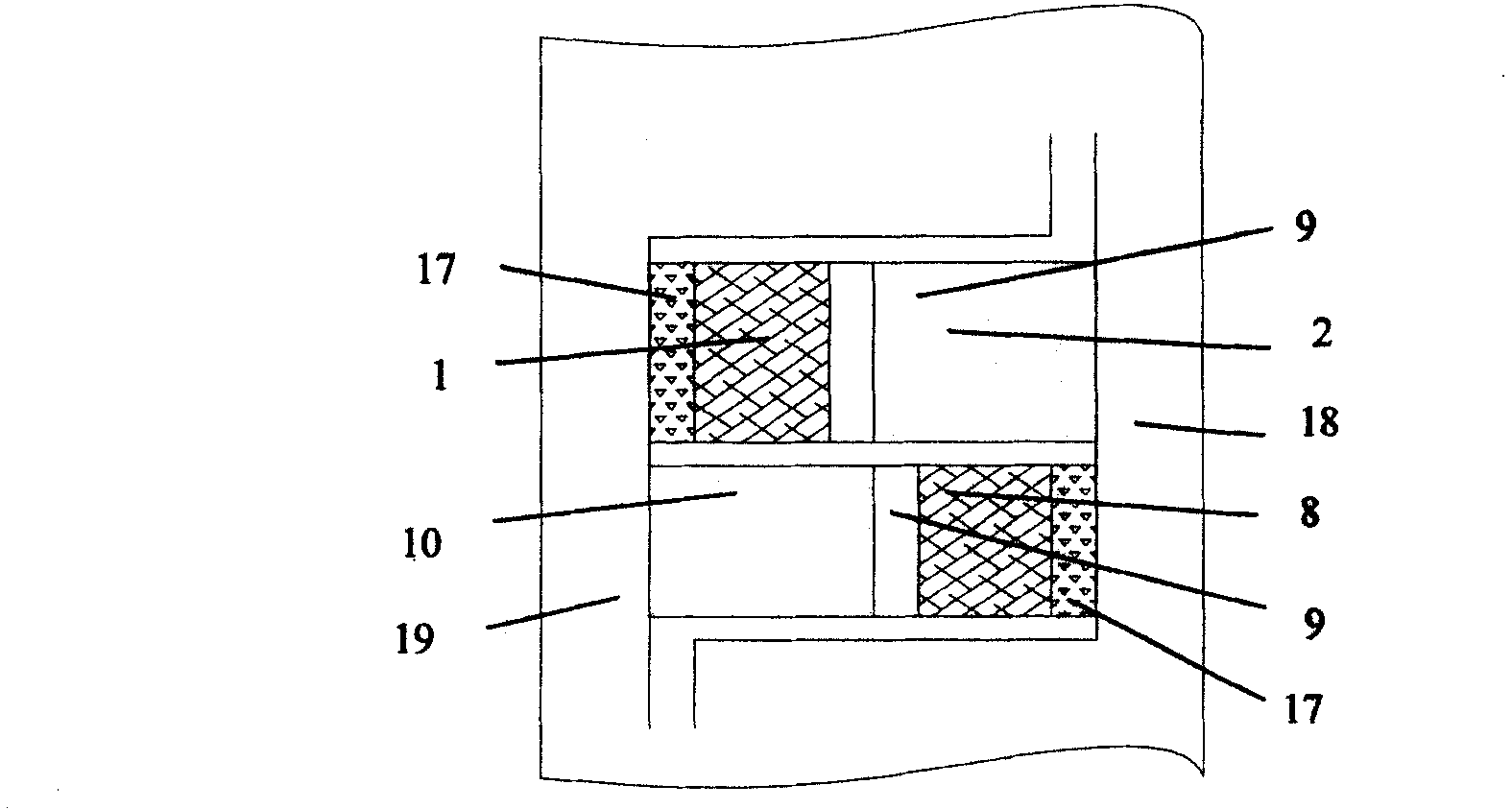

[0025] The outer stator of the motor is similar to the stator of an ordinary motor, with multi-phase symmetrical armature windings 4 embedded in the slots, and a ring-shaped excitation winding 7 placed on the inner stator of the motor. The field winding 7 is fixed on the motor end cover 14 via a magnetically conductive yoke bracket 12 . Since the field winding 7 is placed in the area formed by the inner and outer units of the tile-shaped claw poles, the space utilization rate is high and the structure is compact. The excitation winding 7 is placed inside the rotor, so that each turn of the excitation coil is greatly shortened, thereby reducing the resistance and excitation loss of the excitation winding 7, and improving the efficiency of the motor. In addition, due to the large internal space of the rotor, more excitation coils can be accommodated.

[0026] The use of tile-shaped claw poles facilitates processing and greatly simplifies the manufacturing process.

[0027] By ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com