Novel straight seam welding machine

A new type of straight seam welding technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of inconvenience, low processing efficiency, and very large workload, and achieve convenient use and improve work efficiency. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

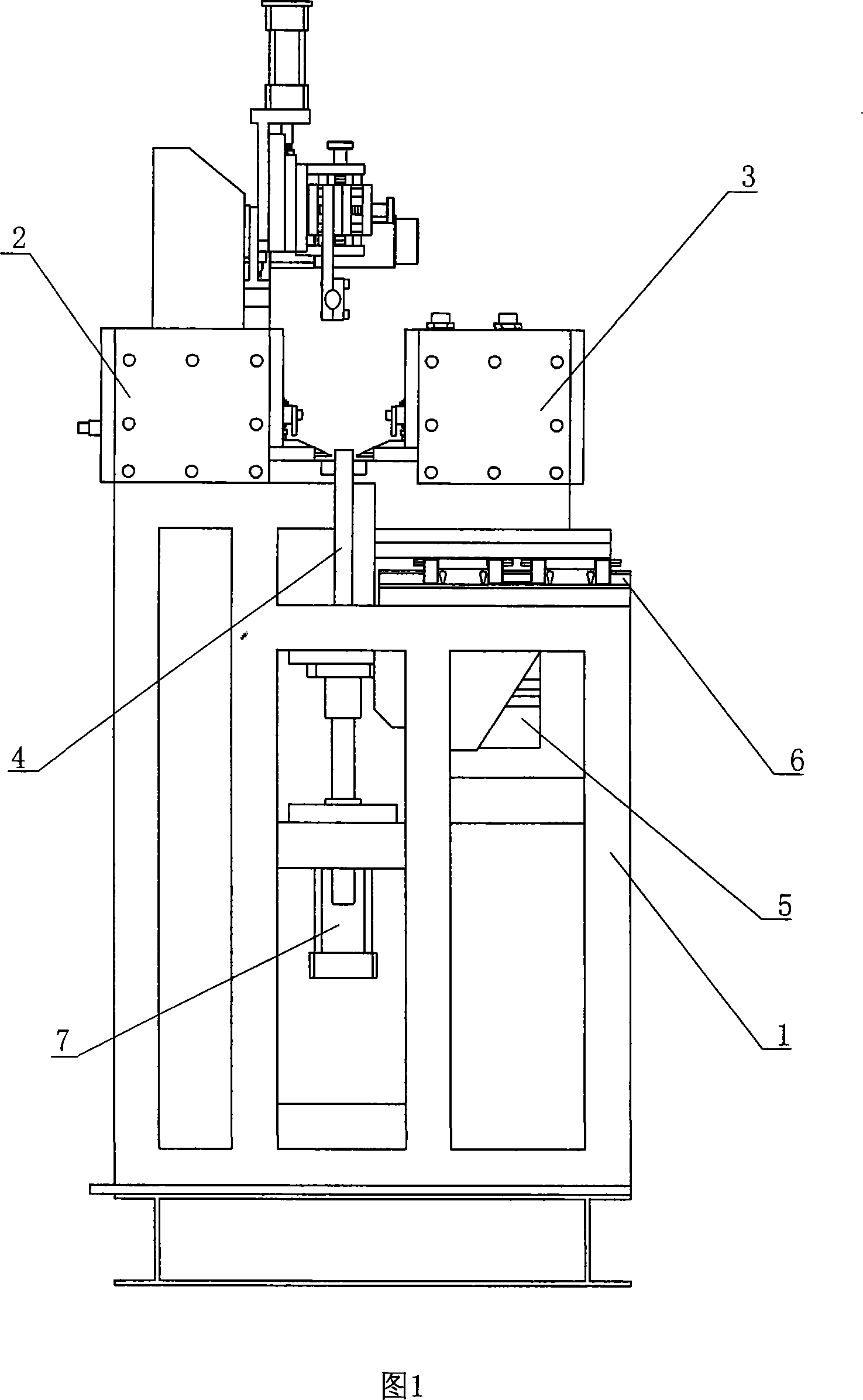

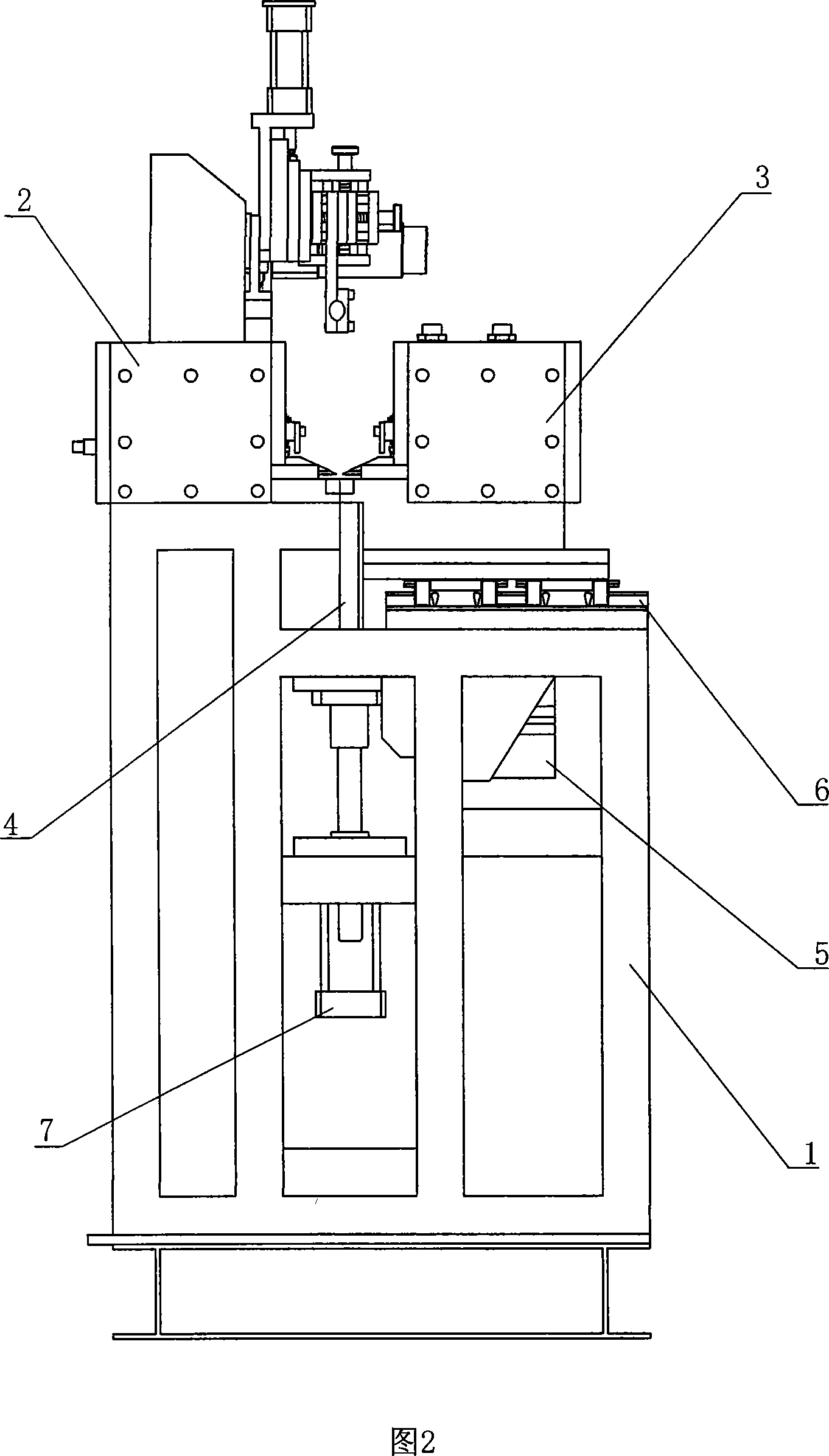

[0021] Referring to Fig. 1 and Fig. 2, a new type of straight seam welding machine includes a body 1, which is provided with left and right clamping beds 2, 3, and the horizontal direction of the clamping table tops of the left and right clamping beds 2, 3 is Alignment, the bottom of the right clamping bed 3 is provided with a slide rail 6, and a driving device 5 drives the right clamping bed 3 to translate along the slide rail 6 in the left and right direction of the body 1, and the body 1 is provided with a limiting plate 4, which limits The position plate 4 links to each other with the driving device two 7, drives the position limiting plate 4 to expand and contract between the left and right clamping beds 2,3 by the driving device two 7.

[0022] The working principle of the present invention is: when metal plate is welded and stitched, first utilize the driving device 2 7 to drive the limiting plate 4, so that the limiting plate 4 is lifted out and placed between the left ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com