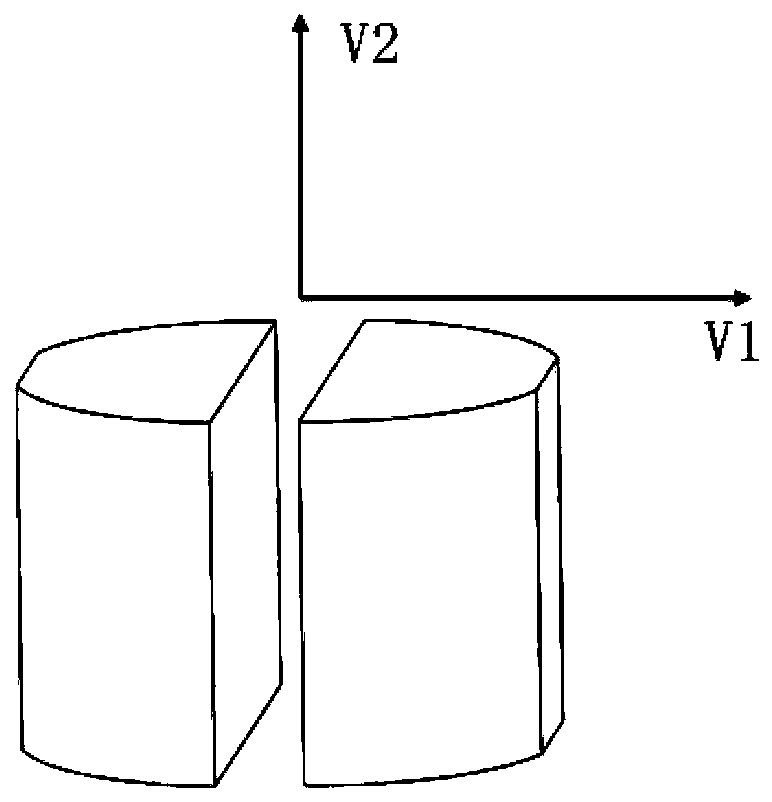

Cylindrical structure anisotropy testing device based on ultrasonic waves

An anisotropy, testing device technology, applied in measurement devices, analysis of solids using sonic/ultrasonic/infrasonic waves, material analysis using sonic/ultrasonic/infrasonic waves, etc. It is difficult to maintain the centering of the transmitting probe and the receiving probe, increasing the complexity of theoretical analysis, etc., so as to improve the test efficiency, save the test time, and save the installation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

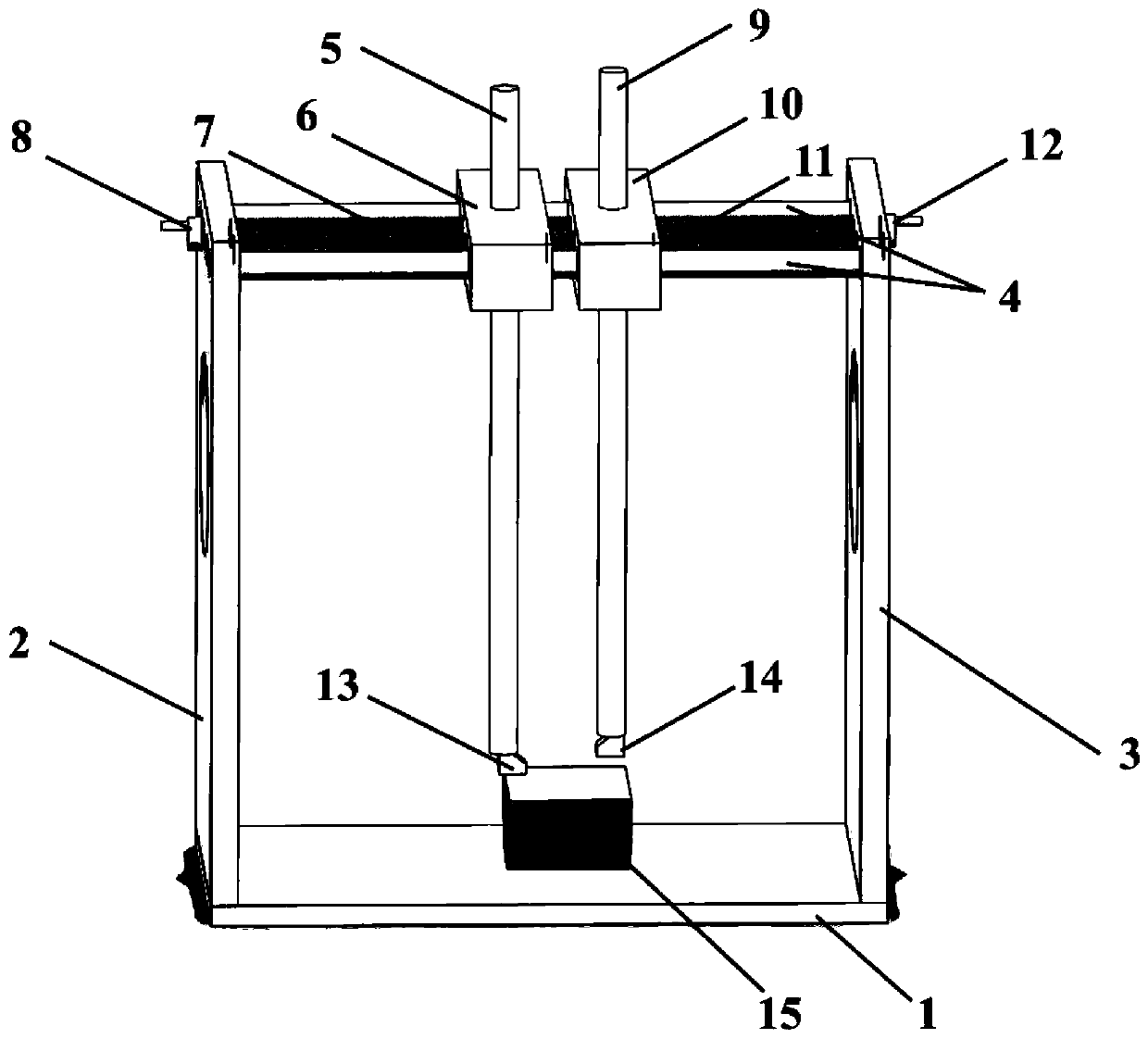

[0013] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below through specific examples.

[0014] see figure 2 , the present invention provides a cylindrical structure anisotropy testing device based on ultrasonic waves, comprising: a bottom plate 1, a left side plate 2 and a right side plate 3 symmetrically arranged on both sides of the bottom plate 1, and a left side plate 2 and a right side plate arranged in parallel Two smooth round rods 4 between the plates 3 and the first screw 7 and the second screw 11, the left slider 6, the right slider 10, the ultrasonic transmitting probe 13, the ultrasonic receiving probe 14, the first screw 7, the second Two screw rods 11 are located between two smooth round rods 4, and the two ends of the first screw rod 7 and the second screw rod 11 are respectively arranged on the left side plate 2 and the right side plate 3 through bearings, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com