Multi-direction round clamping device

A clamping device and circular rotation technology, applied in the field of machining, can solve the problem of not being able to carry out multiple machining processes at the same time, and achieve the effects of improving machining efficiency, beautiful appearance and convenient maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

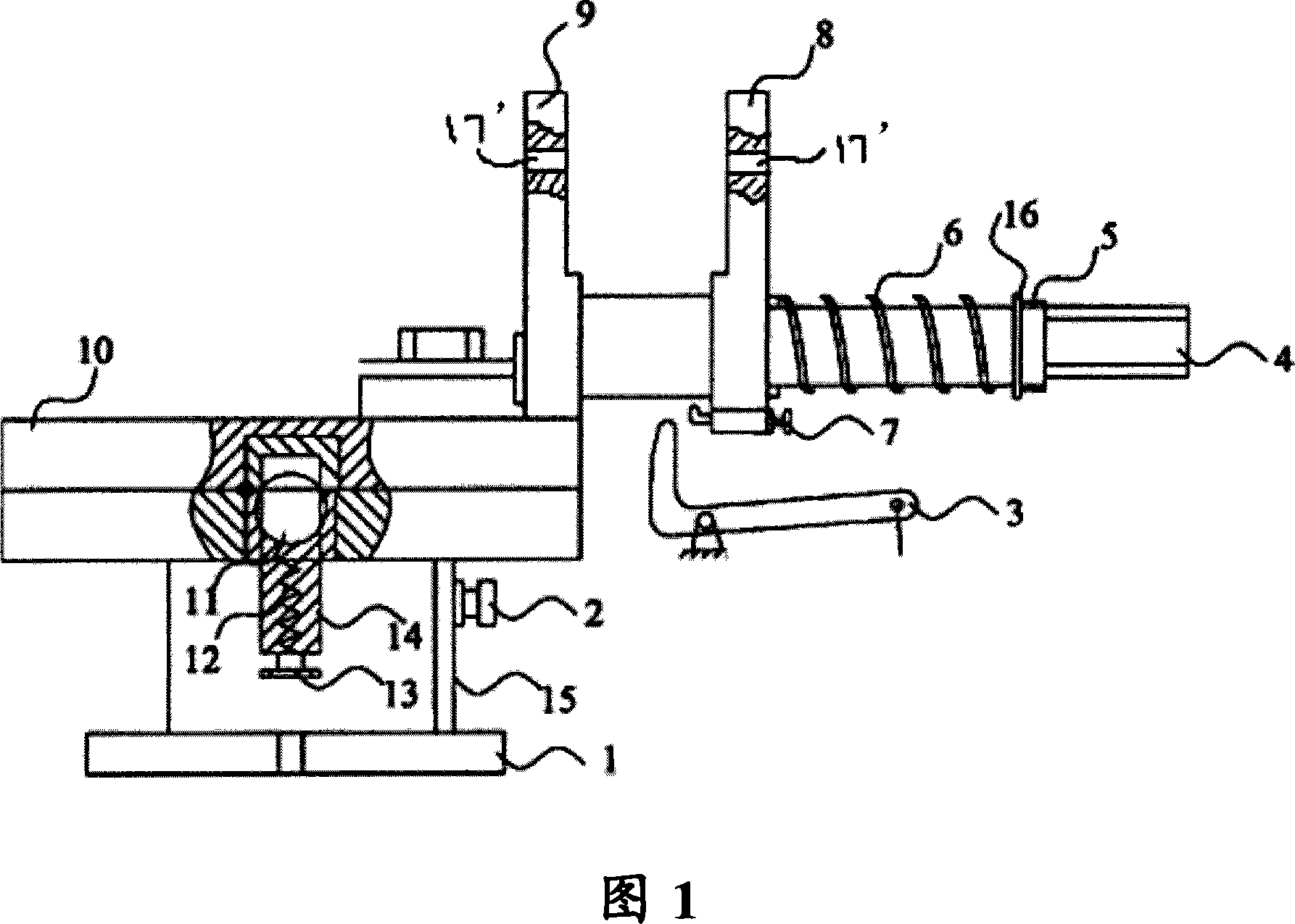

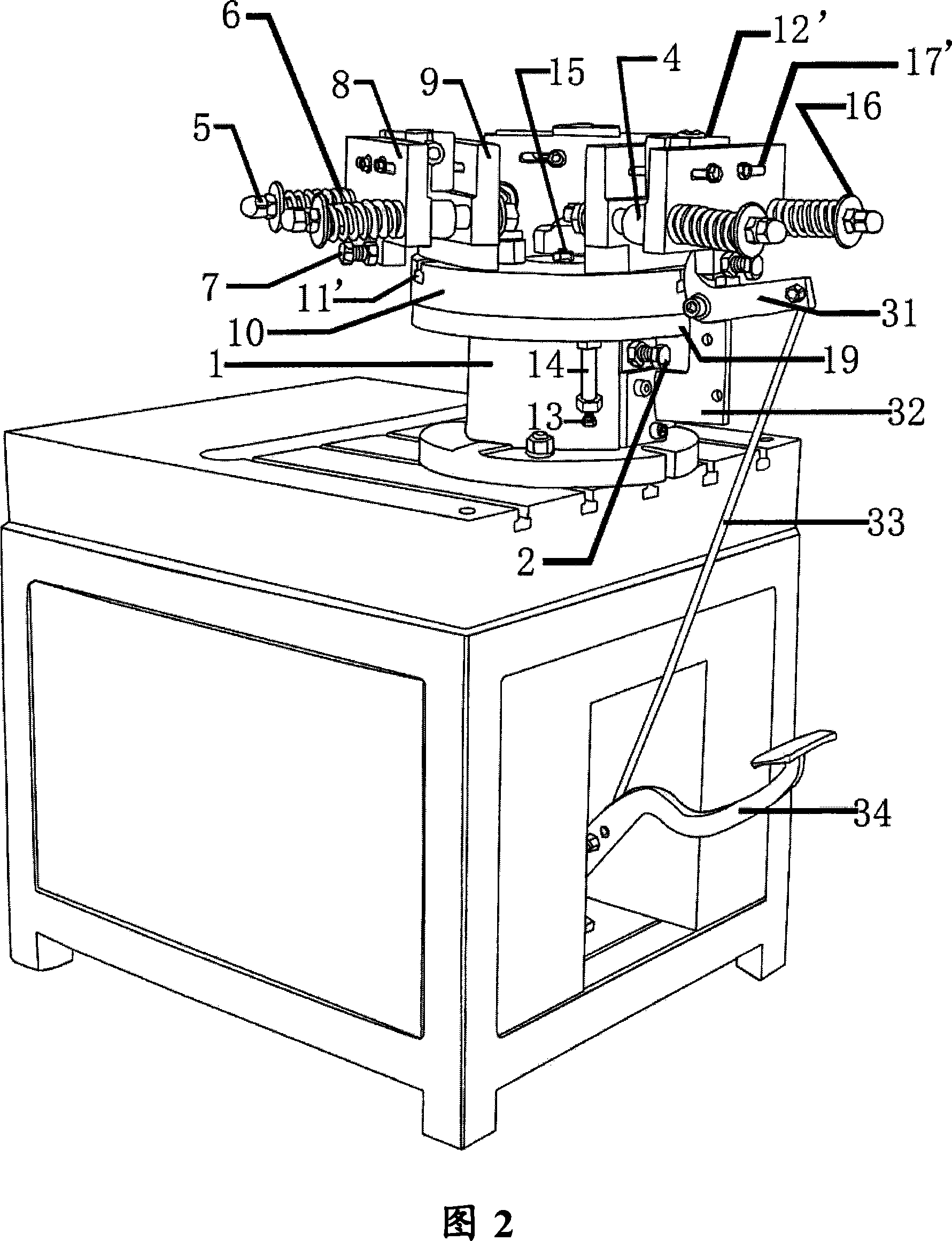

[0020] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments. For the convenience of illustration, the following drawings and descriptions use three vises as examples to illustrate multiple clamping tools, so as to illustrate the multi-directional circular clamping device according to the embodiment of the present invention.

[0021] Fig. 1 shows a schematic diagram of one direction of a three-way vise circular turning device according to an embodiment of the present invention. The three-way vise circular turning device includes: three vises and a circular turntable, one of which is shown in the figure vise.

[0022] The circular turntable mainly includes: a transposition turntable 10, a base plate 1 and a central axis 15, wherein the transposition turntable 10 is connected to the base plate 1 through the central axis 15, and can rotate around the central axis 15, and its upper surface includes t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com