Yarn end cutting method for spinning machine

A technology of spinning machine and yarn tail, which is applied in the field of yarn tail cutting of spinning machine, and can solve problems such as inability to hold yarn

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

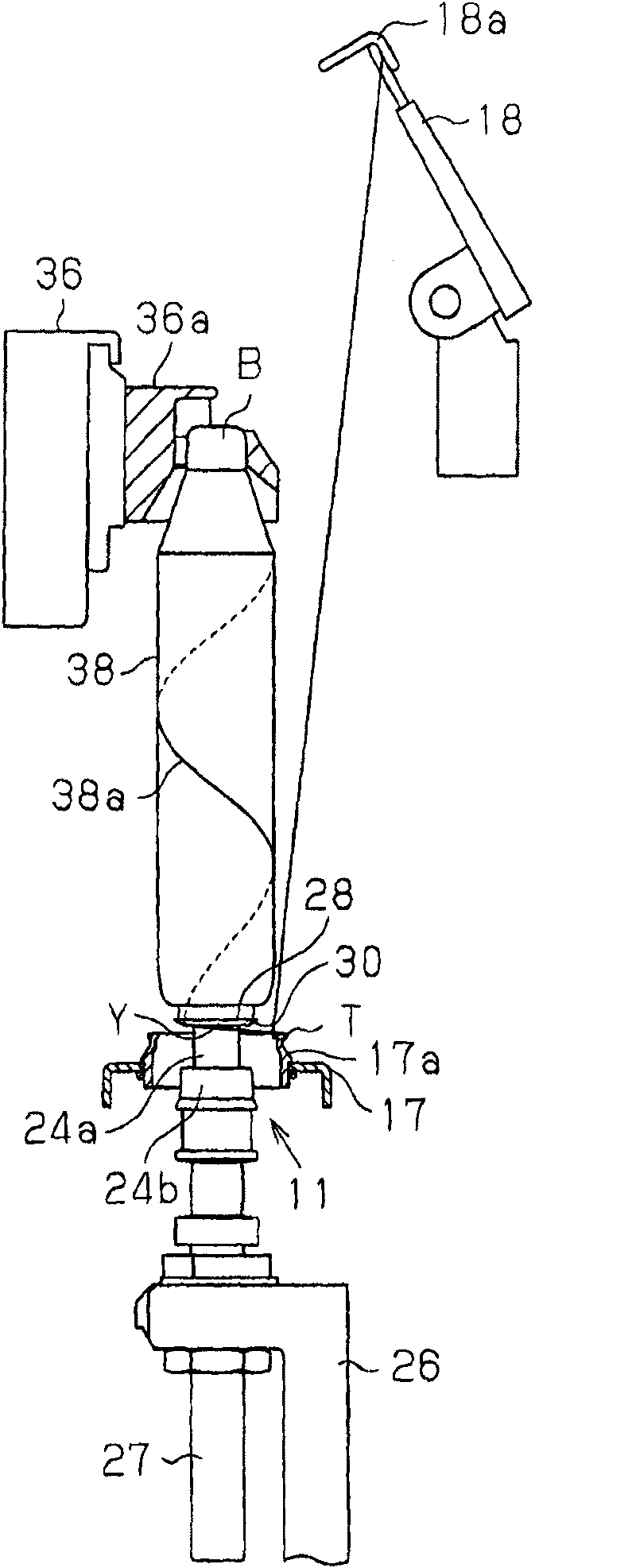

[0020] Below, according to Figure 1A to Figure 5B One embodiment of the present invention will be described. One embodiment shows a method for cutting a yarn tail of a ring spinning frame.

[0021] image 3 A spindle drive system for rotating a plurality of spindles 11 is shown. The spindle drive system includes: a spindle motor 12, a drive pulley 13 driven by the spindle motor 12, a driven pulley 14, and a tangential transmission belt (dragon belt) wound around the drive pulley 13 and the driven pulley 14. 15. A tangential drive belt 15 is wound on a plurality of spindles 11 .

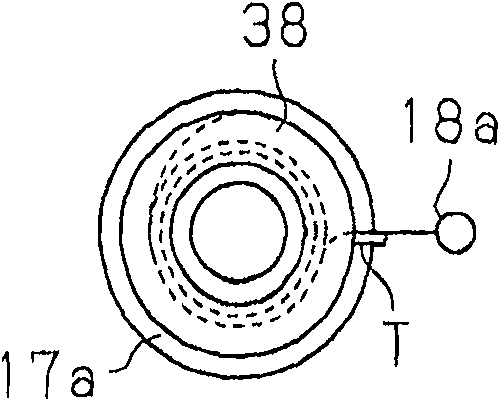

[0022] image 3 A lift motor 23 for lifting and lowering the ring bar 17 is shown. A servo motor is used as the lift motor 23 . The traveler T moves along the ring 17 a provided in the ring shoe 17 . The main shaft 16 is connected to the drive shaft of the elevating motor 23 via a gear mechanism (not shown). The main shaft 16 extends along the arrangement of the plurality of spindles 11 . O...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com