Novel garlic sprout cutting system

A cutting system and technology for garlic seedlings, which are applied to harvesters, agricultural machinery and implements, applications, etc., can solve the problems of damage to garlic seedlings, poor continuous operation ability of garlic seedling cutting machines, and missing cutting, so as to improve the cutting rate and facilitate the cultivation of seedlings in factories. , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

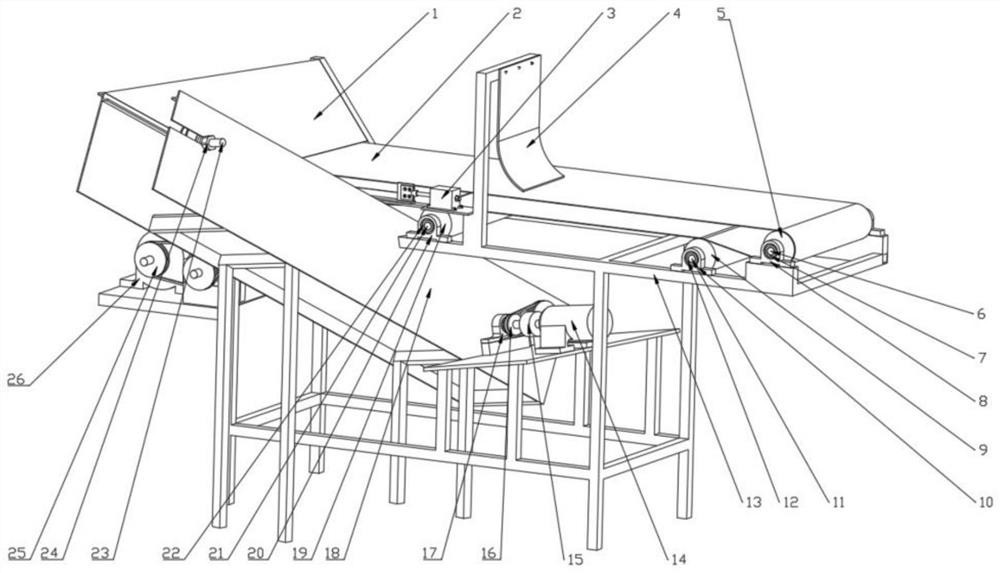

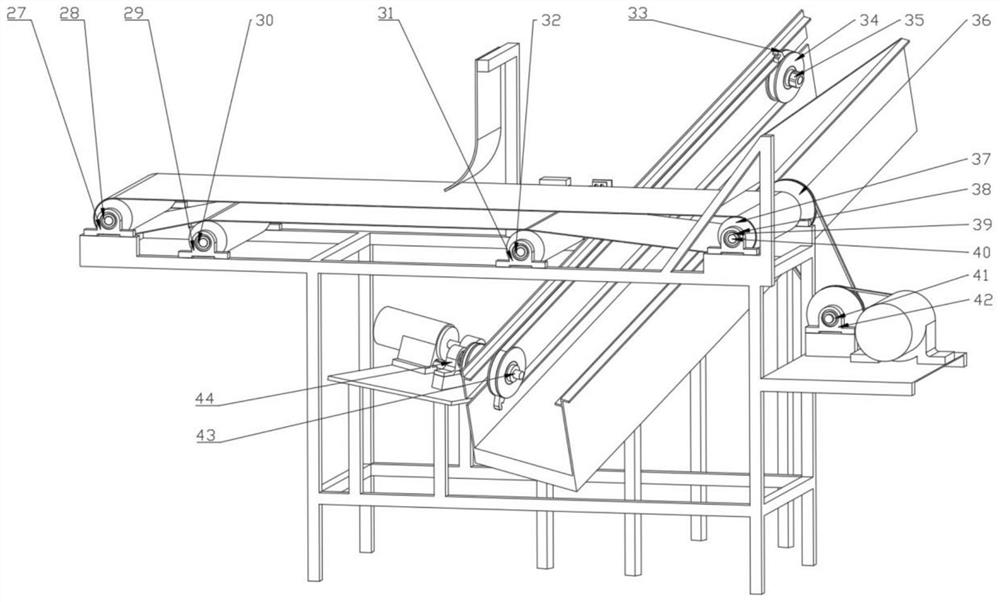

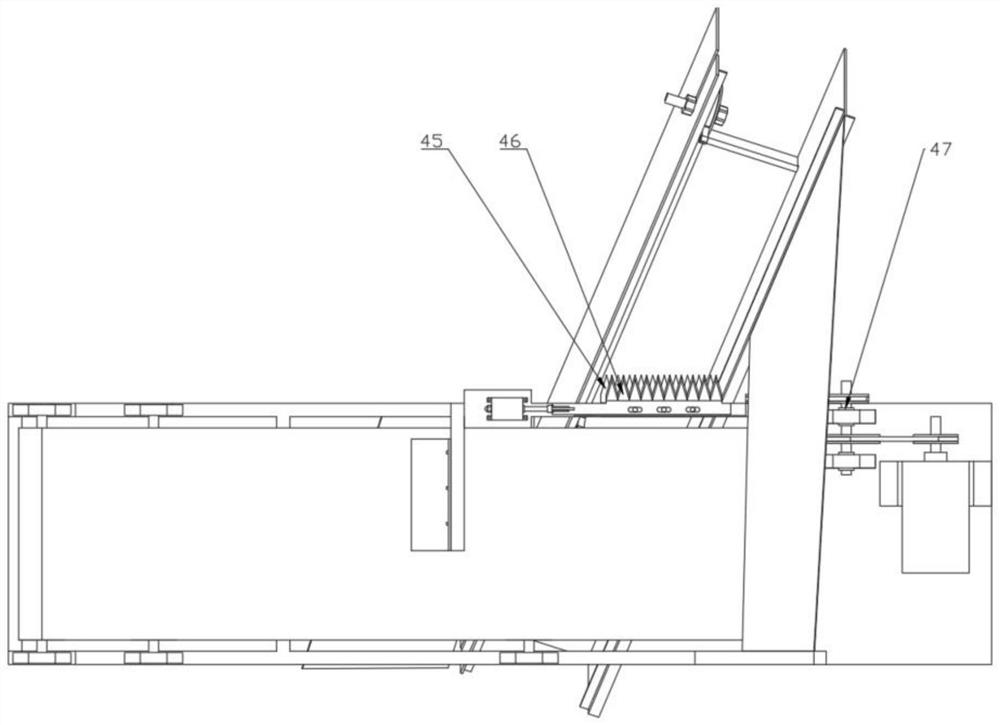

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

[0029] as attached Figure 1-5 : A kind of novel garlic seedling cutting system, comprises guide plate 1, conveyor belt 2 and reciprocating cutting mechanism; Described guide plate 1 is fixed between frame 13 and slide rail 18 by the mode of bolt fixing, drive roller 37 is set, from The driven roller 5, the first tension roller 20 and the second tension roller 9 are respectively assembled with the driving major shaft 40, the driven major shaft 6, the first tension major shaft 21 and the second tension major shaft 11, the The driving long shaft 40 is bolted to the frame 13 by the first bearing 39, the first bearing seat 38 and the second bearing seat 48; the first tensioning long shaft 21 passes through the third bearing 22, the third bearing seat 20, the first The four bearings 32 and the fourth bearing seat 32 are bolted to the frame 13; the second tensioning long ax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com